|

||||||||||||||||||||||||

| Archive | Subscribe | Send to a Friend | www.mhi.org | Solutions Magazine | ||||||||||||||||||||||||

|

Top Story

Technology and Innovation

Emerging technologies such as IIoT, robotics and artificial intelligence provide exciting opportunities for supply chains. The more digitized a supply chain becomes, the more it is at risk of cyberattack. No matter the scale of your supply chain, it is essential to have solid cybersecurity processes in place to manage and mitigate the growing risk of cyberattack.

Switching from manual to digital data management will bring immediate value in the analytics that are available. With multiple solutions available, getting the infrastructure in place to start collecting and interpreting your data can be a challenge. But the benefits of having all of your operational data on hand are almost immediate.

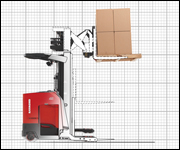

Providers of AGVs are often asked which type of AGV is the best. Clearly, there’s a wide variety of AGV types. All of them have a great deal of flexibility, but some fit particular applications better than others.

Storing and retrieving goods in a warehouse or distribution center is a traditional concept, but exciting innovations are enabling you to become quicker and more accurate to keep up with customer demands.

Autonomous mobile robots are no longer a technology of the future. They are in use in manufacturing and distribution centers right now and operations are starting to see the real benefits of small flexible automation solutions. So how are supply chain operations making use of these flexible solutions?

MHI Updates

During the 2018 MHI Annual Conference, the Material Handling Education Foundation, Inc. (MHEFI) presented two awards to leaders within the material handling community who are pushing material handling education forward. MHEFI also raised $25,000 over the course of the three-day conference. The money will go toward providing financial support for students pursuing material handling, logistics and supply chain education.

Did you know that AGVs have been around since 1953 and have been the catalyst for creating flexible material handling solutions throughout multiple industries? In fact, AGVs have been the most flexible of automated material handling systems and have quickly become a disruptive force leading the way to Intralogistics 4.0.

How can you tell whether your current ergonomics program is adequately protecting your workers? Begin by determining when you last reevaluated it. If it’s been more than a year, chances are good it could use improvement. Are your program metrics or key performances indicators moving in the right direction? Here are some things to consider.

Transportation

Much has been made of how increased tech in transportation trucks and autos can equate to increased vulnerabilities for companies and drivers. But hit those brakes before rushing in blindly and incorporating a “solution” to a perceived and/or anticipated transportation cybersecurity threat: Though the risks of hacking are real, the threat can be mitigated in a variety of ways

Education & Professional Development

Conflict and disagreements are inevitable in the workplace. And if left unresolved, they can waste time and negatively impact productivity. During MHI’s Young Professionals Network webinar “How to Disagree Agreeably” on November 15, you will gain insights into your personality and reactions when dealing with others and learn how to express yourself in a way that promotes acceptance, agreeable outcomes and improved productivity.

Supply Chain Trends

Retail giant Walmart has applied to patent a blockchain system that will enable secure deliveries by autonomous robots. The patent is called “Systems, Devices, and Methods for In-Field Authenticating of Autonomous Robots” and specifies that delivery drones and household robots will be able to authenticate each other using built-in security measures.

A big challenge facing pharmaceutical manufacturers is the stringent requirement of traceability of their manufactured products. Most of the pharmaceutical manufacturers look for traceability that offers them complete tracking of the product from manufacturing through warehousing, up to dispatch.

An important part of the logistics function is the production and warehouse activity that takes place within the four walls of a facility called intralogistics. There are many reasons why Intralogistics 4.0 is essential for today’s industry — globalization, consumer trends, interconnected networks and digital supply chain data among them.

Global Trade

|

||||||||||||||||||||||||