The Digital Workplace is Here, Ready or Not

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

BY CRAIG YEACK, CO-FOUNDER, BCMI CORP.

The construction industry has always been mobile. Project team members, scattered across disciplines and entities, often work remotely, whether at jobsites or while in transit between project sites and trailers or front offices. Sharing project information and tracking deliverables is always challenging. Due to the spread-out nature of project teams and their dependence on in-house software and document management systems, contractors often require a desktop or Internet connection to collaborate.

"Keeping vendors, owners, architects, engineers and field employees up to speed is a momentous undertaking," says Chris Harmon of The Hagerman Group, an Indiana Constructors, Inc. member and general contractor based in Indiana. "There are more changes on jobs now than I’ve ever seen, so there is a greater need for real-time information to keep everything moving smoothly."

The Hagerman Group is one of a growing number of construction companies leveraging cloud-based software solutions and mobile apps to provide the most upto-date project information in the field. By moving project data out of internal systems and into the cloud, these tools create a shared workspace that users can tap into from any location. Project teams equipped with mobile devices (smartphones, tablet computers, etc.) can immediately access documentation and information, make updates in real time and share them with the entire team. They can manage work in progress and track material deliveries and use that information to adjust schedules as issues arise.

To make these digital workplaces a success, however, all team members must be willing to use them. In return, construction professionals who embrace these tools are building skills to advance in an industry that is rapidly adopting new technologies and methods.

MAXIMIZING MOBILITY

Tyler Holbrook, a superintendent with The Hagerman Group, can walk onto a jobsite and have access to everything he needs — without having to carry a briefcase full of folders. He uses his smartphone and iPad to take photos, send emails and texts, and share project information through a cloud-based project management (PM) platform, which includes mobile apps. "I can publish an RFI (request for information) or a change order and the whole team receives it," says Holbrook.

Holbrook uses the PM platform to complete administrative tasks as well as share real-time field-level data with project owners, architects, subcontractors, vendors and their teams. Team members record and track their work through the tool. Since it is compatible with other systems used in the construction industry (like accounting software), they can manage risk and financial reporting.

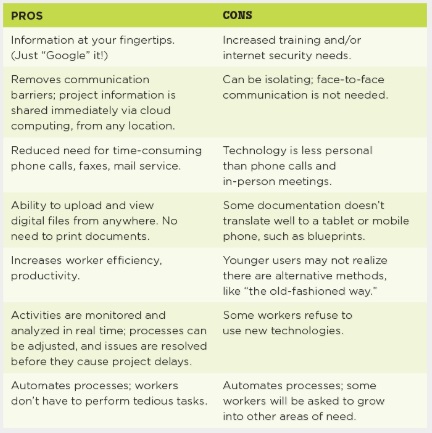

MOBILE TECHNOLOGY ON THE JOBSITE: PROS & CONS

Mobile technology increases productivity by eliminating time-consuming tasks, such as inputting project data via desktop computer, faxing or mailing documents, and placing lengthy phone calls with dispatchers, to name a few. Instead, it gives remote team members direct access to each other via cloud-based software and apps. On one hand, mobile technology allows users to digitally share information in real time so they can work more efficiently. However, it’s still important to build the relationships that make project teams and customers successful. The following are pros and cons of relying on mobile technology, as identified by the contractors in this article.

Superintendents who don’t take advantage of mobile technology, says Holbrook, often find they still have paperwork to do after they get home from a job.

"Mobile apps make me more productive. I capture information easier and I’m faster at tracking performance. I can view a schedule, see how long it takes to complete a task and then create better estimates because of that," says Holbrook. "Plus, for submittals alone, we are saving so much time and money by not having to print anything."

Kris Knox, another superintendent with Hagerman, agrees. "With mobile technology, everything’s in front of you," he says.

As an example, Knox describes how he uses a mobile app supplied by one of Hagerman’s concrete suppliers, Irving Materials Inc. (imi), a member of multiple AGC chapters. Concrete and bulk construction material producers use the app and also provide it to customers as a mutual platform for accessing real-time project information and communicating quickly. Contractors can see where trucks are at any given moment as well as how long concrete pours are taking. They can send mix or volume adjustments to dispatchers or submit new orders without having to pick up a phone.

"If we’re on a big job, with maybe 400 to 500 yards of concrete coming, it’s going to take four hours to get it on the ground and another four hours to get it finished. But conditions can change on an hourly basis," Knox explains. "If you have trucks coming at a five-minute interval and jobsite conditions change so that you have to wait even five minutes to unload, things can get backed up pretty quickly."

As a result, he constantly checks his weather app and uses the mobile app from imi to view truck statuses and even where they are in their routes. He uses that information to decide the best time to move pump locations or whether he needs to reroute trucks or put deliveries on hold. "On one job recently, I saw a pop-up storm coming our way. I used the app to immediately put concrete deliveries on hold and then covered more than 400 yards of freshly placed concrete with plastic sheets before the storm hit," says Knox.

imi sales manager Jeff Kelly says by giving customers mobile tools, the concrete supplier provides the transparency needed to avoid miscommunications and streamline the order process. "Field supervisors like to use the app to see how things are going," he says. "They also look at their historical data to see how products have been ordered in the past and fine-tune their processes."

Therefore, says Kelly, "Sharing our information with customers is not just expected, it’s a must. It has to be fast, and it has to be accurate, so we can constantly communicate with contractors." When both parties have access to the same information, it’s much easier to find room for improvement.

As companies like imi and Hagerman bring more mobile tools to jobsites, Knox believes workers who do not utilize technology will suffer setbacks in terms of productivity and career advancement.

A MULTIGENERATIONAL APPROACH

Chris Harmon is the director of field operations in The Hagerman Group’s northern Indiana region. He is responsible for providing his direct reports and project partners (i.e., subcontractors) with the digital tools his company uses. "I let them know using our tools is a priority," he says. "I also keep tabs on what training is needed and make it available to them."

However, some age groups are more comfortable adopting new technologies than others. While tech-savvy millennials — like 33-year-old Tyler Holbrook — take mobile connectivity, cloud computing and other tools for granted, industry veterans can be resistant to change. (For this article, a millennial is defined as a person who is 35 years old or younger.) For example, although Kris Knox, who is 45, embraces technology on the jobsite, he admits, "I don’t carry my iPad all the time. Some of the younger guys always do."

Harmon breaks down his local workforce into three categories: younger people who expect to use technology such as mobile apps, "middle-of-the-road" types who use them but not as intuitively, and some who refuse to use them at all. With the exception of the last group, the company strives to reach employees in their own comfort zones through a multifaceted training and mentoring approach.

Structured, classroom-style training through The Hagerman Institute, an employee-growth initiative managed by a full-time employee. Classes are used to onboard new hires as well as train long-time staff on new tools and technology. Ongoing support is provided through refresher courses.

Informal, one-on-one instruction through mentorships. Although younger employees typically learn from older employees, these relationships are also opportunities for mentors to learn about technology from their mentees.

As-needed support through peerbased resources. Much like in-house safety experts are cultivated, select employees who champion technology attend conferences and user training offered by Hagerman’s software providers, so they can, in part, serve as go-to technology experts within the company.

While there is never a replacement for face-to-face conversations, mobile technology untethers project teams, so they can share project details more efficiently in the field. Construction professionals who are willing to master industry-specific cloud-based solutions and mobile apps will be well-positioned to take their companies — and their careers — to the next level.

"The industry is changing, so you have to keep up," advises Holbrook.

Craig Yeack has held leadership positions with both construction materials producers and software providers. He is co-founder of BCMI, Corp. (the Bulk Construction Materials Initiative), which is dedicated to reinventing the construction materials business with modern mobile and cloud-based software. Contact Yeack via email at Craig.Yeack@bcmicorp.com.