Plasma Cutting Maintenance: Are You Throwing Money Away?

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

You may be if you aren’t scrutinizing your consumables use

During almost every shop visit I hear the same question: "How can I make my business more productive and yet save money?" The answer is simple: Take a look at your consumables.

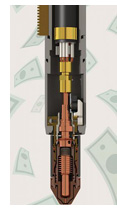

It’s a common sight on the cutting shop floor: Next to every CNC plasma cutting machine is the 5-gallon pail of "used up" consumables. Mostly copper, these spent consumables eventually find their way to the recycling bin.

Quite often I reach into this bucket and pull out a handful of parts to review. I see the erosion of the electrode and the swirl marks on the nozzle. The condition of the nozzle and shield orifices often tells a story about either the condition of the plasma cutting system itself or of training issues that should be addressed with machine operators. Sometimes as much as 40 percent of the parts in the scrap pail can go right back in the torch, where they can continue to produce parts with excellent cut quality.