Print this Article | Send to Colleague

Print this Article | Send to Colleague

Interior Railings - Nonferrous, Nonforged

All railings including custom castings and cold forged elements with less than 5% custom hand forgings

Gold Winner:

Klahm & Sons Inc.

Ocala, Florida

These interior railings were placed in a three-story townhouse. The railing is made of aluminum with a contemporary bronze cap rail and 3/4" brass balls. At the beginning of each stair there is a large forged tapered lambs tongue. The oval design is made of 3/8" x 3/4" flat bar. The diagonal rods are pierced through the flat bar. Custom aluminum cast collars contribute to the contemporary design. All of the vertical pickets were run through a special dye on the embossing machine. The bronze has an oil rubbed finish. The main body of the railing has a gunmetal finish with Micah added to enhance blues, green, and other colors unlike Silver metallic paint. The decorative element was painted an aluminum color with four coats of transparent gold.

This project took approximately 800 hours.

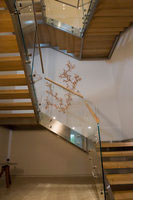

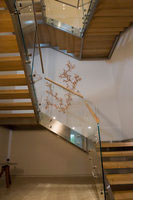

Silver Winner:

Art's Work Unlimited

Miami, Florida

This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads.

This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads.

This project took approximately 376 hours.

Bronze Winner:

Upright Iron Works Inc.

Griffith, Indiana

These railings were installed in a British school in Chicago, Illinois. They were fabricated on three stairs and were designed by the architect on the project. Two of the three stairs went up two floors with a total of four runs. The other stair went up three floors, which had six runs. The main framework was fabricated with carbon steel pipe: 1 ½" sch 40 pipe for the top bar and 1 ¼" sch 80 pipe for the posts. The rest of the railing was stainless steel: frame ¼" x 1" stainless steel flat bar, 1 ½" x 3/8" opening "U" edging and Banker Wire L-62, ¼" thick wire mesh with 2" centers. All stainless steel had a polished #4 finish.

This project took approximately 1,048 shop hours.

Back to NOMMA Newswire

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads.

This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads.