Temperature Affects Outdoor Handrails

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

The expansion and contraction of metal due to temperature changes could affect the design of your outdoor handrails.

By John L. Campbell

Where temperatures vary as much as 60° F in a 12-hour period, the expansion/contraction of metal handrails can present a challenge. Under such circumstances, 200 feet of aluminum handrail can expand and contract by 0.96 of an inch. That’s almost half an inch per every 100 feet. Aluminum has the highest coefficient of expansion/contraction. Carbon steel would be affected less than half that amount. Stainless expands at a rate that is 30 percent less than aluminum. And brass and bronze rank second in variations due to temperature changes. So, as one astute engineer observed, "When our forebears designed the split-rail fence, they knew what they were doing. They compensated for the affect of temperature even on wooden rails."

Safety handrails are seldom over 100 feet, and with most industrial handrails, vertical supports are set loosely in pipe bases, cans imbedded in concrete. The cans are larger in diameter by 1/8 of an inch or more, which is enough to allow for expansion and contraction of horizontal rails. Installers may not consider heat and cold factors when they bury anchored uprights in concrete, attaching horizontal rails by welding. However, the cyclical changes of temperature extremes can result in warpage and shearing of bolted attachments. Taking temperature changes and the material of construction into consideration along with pre-planning the design can increase the service life of handrails.

Expansion/Contraction (£)

Due to Temperature

Decimals are for inch/inch per degree Fahrenheit

Aluminum .0000133"

Brass/Bronze .0000104"

Stainless Steel .0000096"

Carbon Steel .0000192"

Despite the fact that outdoor railings expand and contract with changes in temperature, many NOMMA fabricators indicate that the issue of expansion joints rarely comes up (see NEF’s February 2004 Fabricator’s Journal).

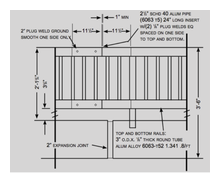

An Expansion Joint Diagram

By Allen Guidry, Florida Aluminum and Steel Fab. Inc.

A recent job required NOMMA member Florida Aluminum and Steel Fab. Inc., Ft. Myers, FL, to allow for expansion joints in an outdoor railing system. The illustration at right depicts the expansion joint Allen Guidry designed for the job, which allows for a 2-inch expansion. A collar (not shown in the diagram) fits over the expansion joint to enhance its aesthetic appearance. Like the joint, the collar is fixed on the left but open on the right. The collar fits very close to the rail and is tapered for a flush fit.

*This article originally ran in the March/April 2004 issue of O&MM Fabricator.