Stairs Complete (Residential)

In order to be placed in this category, the majority of the stair must be of metal construction and installed in or on private residence.

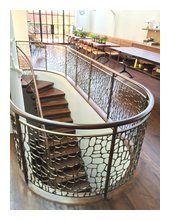

Gold Winner:

M. Cohen & Sons Inc.

Broomall, Pennsylvania

The design of the custom stairs was done by an architect. Some of the features included are bronze railings that were antiqued and waxed and wood treads that were stained and sealed. The stair structure, which is hidden in the wall, is made of steel. The railings are bronze, cast and bar stock. There is also cantilevered stair with structural steel stringer in wall. Built-up steel tread assemblies were bolted to in-wall stringer, shimmed, and fully welded. Wood treads were fully shop assembled and slid onto the steel subtreads. The "jali screen" of the guardrail was cast out of bronze from a hand-formed wax mold. In turn, the screen was welded into the guardrail assembly. All fasteners were concealed for a seamless end product. The greatest challenge for this team was achieving the fluid curve of the stair while cantilevering from a single tread. In addition, the custom wood profile for the stair treads was challenging to both fabricate and install.

This project took approximately 3,279 hours.

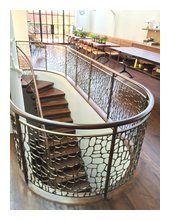

Silver Winner:

Grainger Metal Works

Nichols, South Carolina

The finish used on this stair project was a powder coat. Aluminum rectangular tubes were used for the platform and stringers which allowed chases for the wiring for the light system. The railings are aluminum with custom chisel lined and twisted pickets with a custom forged decorative panel made with custom flat bar 5/16 x 5/8 which was made from 5/8 sq. bar. The treads are inlayed with rubber mats and lights mounted under the handrail. The owner furnished the decorative etched glass panel. The greatest challenge for this team was fitting the platform framing onsite while being on scaffolding. The curved stone wall supporting the waterslide was a very inconsistent curve. Several thin paneling templates were made for the floor and many measurements and cross measurements were made, discussed, and voted on before breaking down the on-site fitted framing. In the end, it fit nicely. We used 2-1/2" thick rubber playground mat material for the tread infill which made walking barefoot on the treads kid friendly.

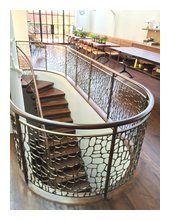

Bronze Winner:

Iron Decor

Tulsa, Oklahoma

This complete stair system has a single stringer attached at the ground floor and the second floor joist. An architect provided a concept sketch and the steel stringer sizing. Vertical bar brackets were welded to the side of the mono-stringer to support each of the treads. The treads are solid wood beams cut the thickness of the rise of each step and notched to clear the mono-stringer. The treads were stacked one on top of the next at the stair angle with an overlap for attachment. The ¾" round bar balusters were hammered for texture and flattened on the end for side mounting into the solid treads using square headed lag fasteners for an antique look. The natural steel finish was satin clear coated.

This project took approximately 198 hours.