NOMMA's newly-redesigned O&MM Fabricator magazine continues to receive positive feedback! We have a great editorial lineup for 2016, and each issue will be full of industry-related material with a bonus of one or two business-type articles to help you with team management, marketing tips and more. NOMMA's newly-redesigned O&MM Fabricator magazine continues to receive positive feedback! We have a great editorial lineup for 2016, and each issue will be full of industry-related material with a bonus of one or two business-type articles to help you with team management, marketing tips and more.

This almost 70-page magazine wouldn't be possible without advertiser support. We would love to continue growing each issue so that we can provide more articles that will educate and benefit you. If you are planning your marketing dollars for 2016, consider supporting

NOMMA and its publications by purchasing an ad. Not only will you be getting great exposure for your company, you'll be contributing to the success of NOMMA's national publications.

Act now to secure your spot by contacting publication director, Beth Palmer, for advertising opportunities. You can reach her by calling 352-333-3404 or by emailing bpalmer@naylor.com.

|

NOMMA's Fall Workshop will be held on December 5 at 8 a.m. at the O.K. Foundry Co. Inc. in Richmond, Virginia. This is a one day joint event of the Northeast and Chesapeake Bay Chapters of NOMMA. We encourage all of our area members to attend for a day of networking and learning. If you plan to attend, please make sure you pay the $69 by November 30. This cost includes your meals and handouts.

Contact Todd Daniel for more information. He can be reached by phone at 888-516-8585 or email, todd@nomma.org.

|

Be sure to register for the industry event of the year!

The METALfab Annual Meeting will be held March 16 through March 19 in Greenville, South Carolina.

|

The 2016 ABANA Salt Lake City Conference will be held in Salt Lake City, Utah at the Utah State Fairpark from July 13 through July 16. There will be demos of architectural and sculptural blacksmithing,

foldforming, and more. There will also be teaching tents with hands-on participation with the demonstrators, professional seminars, a fine art gallery with an auction, a marketplace, and so much more!

Reserve your hotel now and pay later! There will also be on-site camping available.

|

Dave Kraninger Has Been Appointed Executive Vice President for Sales and Marketing for The Wagner Companies

Dave comes to Wagner with over 24 years of experience in sales, marketing, product management, business development, product development, technical project management and manufacturing. He also has experience as a manufacturing engineer and production supervisor.

Most recently Dave was with Master Lock Company, a subsidiary of Fortune Brands Home & Security, where he was the Vice President of the Commercial Safety and Security business unit. Dave also spent time with Briggs and Stratton Technologies and Weasler Engineering. Dave has a BS degree in Mechanical Engineering and an MBA - both from Marquette University.

As the Executive Vice President for Sales and Marketing, Dave will be responsible for increasing sales in the Architectural metal and glass marketplaces and the promotion of the Wagner standard product line. Additionally, he will continue to develop and improve the Wagner web presence, social

media and customer outreach programs.

Congratulations, Dave!

|

If you do, please be sure to share this information with our new

NOMMA editor in chief, Marbella Miller. We love to feature news, updates, tips, etc. from our members and friends in the industry in both the O&MM Fabricator and in the NOMMA Newswire eNewsletter. You can reach Marbella directly by emailing her at marbella@naylor.com.

|

Now is a great time of year to get pictures for your projects. Up until December 1 you can enter for a discounted rate of $50.00.

In order you enter, you will need to:

• Email your photos and job description here: topjob@nomma.org

• Pay for your entry by visiting THIS site. • See the rest of the Rules HERE.

|

In order to be placed in this category, all gates and/or doors, excluding driveway gates must contain custom hand forged elements.

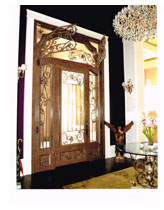

Gold Winner:

Atrium Homes

El Paso, Texas

The design was inspired by the Designer and drawn by the fabricator. The complete project from drawings, finish selection,

fabrication and installation took almost 1.5 years. The complete Unit with transom and sidelights measures 9 ft. wide by 13 ½ ft. tall. The actual operating door itself is 4 ft. wide by 10 ft. tall. One of the biggest challenges was to have identical iron work detailing on both sides of the transom and

sidelights, and to be able to open the scroll work to clean the glass when needed. Therefore, custom hinges were fabricated and added within the frames to disguise the clasp that show that both sides open. The second challenge was the finish. We used a two-part Urethane color as a base then a custom technique was applied by hand first with one color, then a second color with similar technique was applied and finally a top coat of Clear Guard.

The fabrication took 640 hours and the finish took 120 hours.

Silver Winner:

Wiemann Metalcraft

Tulsa, Oklahoma

Wiemann Metalcraft created a forged door and jamb for a residential home.

The door measures 9' by 4'-6'

The most difficult part about this project was the curved jamb and the glass.

Bronze Winner:

Loyal Wrought Iron Co. Ltd.

Guangzhou, China

This door mixes traditional and modern culture and represents the popular trend nowadays.The door consists of six big Chinese Knots, inherits Chinese traditional culture and expresses best wishes. The bronze flowers catch people’s eyes at first sight and is the finishing point of this door. The door is made of Low Carbon Steel and holds bronze flowers, a double-sided lock with handles, 3/4" tempered insulated glasses and removable fly-screen, etc. The door was created with mixed cutting techniques and forging. The scroll works was made by skillful workers and the smooth curved plate was done by exacted machines. The greatest challenge to make this door was the symmetry; symmetry of two door slabs, symmetry of the same door slab. Every small part of one slab is the same as another slab, and you can find the same ones in the same slab as well. So it requests exact radian, correct direction and precise dimension of each scroll works. The Electrophoresis technique was used instead of the galvanizing technique, which is better to prevent the door from rusting. The door has powder coating not spray paint. A faux finish was done with a brush at the end.

This project took approximately 210 hours of labor.

|

The Stainless Steel Building & Construction Library is a one-stop, non-commercial technical resource compiled by the International Molybdenum Association (IMOA) and the Nickel Institute.

Highly valued by architects, engineers, fabricators, building owners, contractors, and others working with stainless steel in the building and construction industry, this is a comprehensive, downloadable collection of the best free technical information, resources, articles and case studies available anywhere.

|

|

Kerwin Lund has been blacksmithing for 30 years, and he's been a Civil War 7th Cavalry re-enactor for 15 years.

But it wasn't until four years ago that the Hazen, N.D., man decided he'd bring his favorite hobbies together and build a replica Civil War-era traveling forge.

"It was time to combine. I had to do it," Lund said Saturday at the Western Minnesota Steam Threshers Reunion.

|

|

The end of the calendar year means a lot of things for small businesses. It's time to start thinking about what you want to achieve next year and work on your formal goal setting process. Your are probably in the midst of holiday shopping for your employees, vendors, clients and colleagues. And, of course, it's time to start closing out your books for this calendar year.

|

|

With 2015 coming to a close soon, we wanted to provide some tips in continuing to ensure your shop follows OSHA and EPA standards as well as any shop rules that have been put in place. You can make sure your 2016 starts off on the right foot with these 40 Basic Shop Safety Rules.

|

|

| |

|