The January/February Issue of O&MM Fabricator will be at METALfab in March!

We have a great editorial lineup for 2016, and each issue will be full of industry-related material with a bonus of one or two business-related articles to help you with business management, marketing tips, and more! Visit nomma.org to access the digital edition of past issues of O&MM Fabricator.

This industry resource wouldn't be possible without advertiser support. We would love to continue growing each issue so that we can provide more educational and beneficial articles to you. If you are planning your marketing dollars for 2016, consider supporting

NOMMA and its publications by purchasing an ad. Not only will you be getting great exposure for your company, you'll be contributing to the success of NOMMA's national publications.

Act now to secure your spot by contacting publication director, Beth Palmer, for advertising opportunities. You can reach her by calling 352-333-3404 or by emailing bpalmer@naylor.com.

|

Make Sure You Register for METALfab2016 While There's Still Time!

Be sure to register for the industry event of the year!

NOMMA's Annual Meeting will be held March 16-19 in Greenville, South Carolina. This year's Annual Meeting will include invaluable education sessions, live demonstrations, a great presentation from keynote speaker Sam Wyche, and much more!

|

Register Now for the 2016 ABANA Salt Lake City Conference!

The 2016 ABANA Salt Lake City Conference will be held in Salt Lake City, Utah at the Utah State Fairpark from July 13-16. There will be demos of architectural and sculptural blacksmithing,

foldforming, and more. There will also be teaching tents with hands-on participation with the demonstrators, professional seminars, a fine art gallery with an auction, a marketplace, and so much more!

Reserve your hotel now and pay later! There will also be on-site camping available.

|

Do You Have Exciting News to Share About Your Company or Information That Can Help the Industry?

If you do, please be sure to share this information with our NOMMA editor, Marbella Miller. We love to feature news, updates, tips, etc. from our members and friends in the industry in both the O&MM Fabricator and in the NOMMA Newswire eNewsletter. You can reach Marbella directly by emailing her at marbella@naylor.com.

|

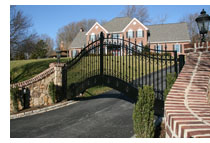

Driveway Gates (Non Forged)

In order to be placed in this category, all driveway gates including custom castings and cold forged elements will have less than 5% custom hand forgings.

Gold Winner:

Compass Ironworks Compass Ironworks

Gap, Pennsylvania

Compass Ironworks was provided with a low-res, grainy sketch of a design that a return client really liked. After researching the design, the Compass Ironworks team found that it dated back to England in 1861. The client gave a deadline of six weeks to completion, and there were numerous custom castings. The entire design was drafted in CAD for the client’s approval. To be time efficient, all casting patterns for the gate were created in-house and sent overnight to the foundry. The client also desired the look to be authentic cast iron hinge posts which would have added $6-8,000, so the suggestion was made to do trim detail and 45-degree corners and rosettes to capture the authentic look.

The deadline was extended by two weeks as the castings provided some fitting challenges and needed machining. All the rosettes were forged; over 500 in two different sizes. The installation was done in the dead of winter because the client wanted security and privacy as soon as possible.

It took approximately 476 hours to complete the gate.

Silver Winner:

Atlas Custom Metalwork

East Hanover, New Jersey

These custom driveway gates were designed by the fabricator along with the homeowner. They were created with all aluminum and copper. The majority of material is 1" sq. tube, and the frames are 2" sq. tube. The vines are 1/4" round bar, and the six panels are .125 aluminum sheet, powder coated and sandwiched with 16 oz copper sheet. The frames for the panels were grooved so the panels could 'float' within. The leaves, vines, and six castings were painted with bronze and copper paint after everything was powder coated with Tiger Drylac black matte. These custom driveway gates were designed by the fabricator along with the homeowner. They were created with all aluminum and copper. The majority of material is 1" sq. tube, and the frames are 2" sq. tube. The vines are 1/4" round bar, and the six panels are .125 aluminum sheet, powder coated and sandwiched with 16 oz copper sheet. The frames for the panels were grooved so the panels could 'float' within. The leaves, vines, and six castings were painted with bronze and copper paint after everything was powder coated with Tiger Drylac black matte.

Bronze Winner:

BenFab Inc.

Lansdowne, Pennsylvania

These driveway gates were made for a private residence. They measure approximately 20 feet in span and 7 feet in height. The material used for the gates was three quarter inch aluminum square tube pickets, two inch by one inch rolled aluminum channel intermediate horizontals, two inch by two inch square tube rolled frame, three-eighth inch laser cut bottom panel, and scroll infill design with finials. The client gave instructions for the gates to open inward on an inclined driveway. In order to accommodate this request, both the bottom and the top of the gates needed to be arched. A satin black powder coat was used for the finish of the gate.

It took approximately 250 hours to complete the work.

|

Make Sure You're Up-To-Date on the New UL 325 Changes. The Following Article Provides Insight for the New Mandates:

Changes Coming to UL 325 for Gate Operators

RICK SEDIVY, DOORKING DIRECTOR OF MARKETING AND REGULATORY AFFAIRS, AND TOM DESILVIA, LIFTMASTER DIRECTOR OF ENGINEERING FOR REGULATORY AND TEST SERVICES

Starting on Jan. 12, 2016, new UL 325 changes take effect, bringing a series of new mandates for the gate operator industry. Here’s a quick guide to the key modifications.

Since 2000, gate operators have been required to have two independent entrapment protection devices for each area requiring entrapment protection. The changes listed here will affect manufacturers as well as installers.

For example, manufacturers need to ensure that a gate operator can detect (1) that each external entrapment protection device is connected and functioning properly, (2) that a Type E audible alarm is not one of the required means of entrapment protection, and (3) that their instructions have been properly updated.

Installers need to understand the new requirements and ensure that the products are installed in accordance with the instructions and local codes. This may include installing external devices that are new or different from ones used in the past.

*SOURCE CREDIT: Reprinted in the November/December issue of O&MM Fabricator with permission of Door & Access Systems Magazine

|

Conserving Consumables

When Applicable, Fabricators Benefit From Switching to Automated, Spooled-Wire Welding Techniques

Consumables rank high among all the variables that go into creating an efficient production operation. However, when it comes to the welding process, taking a hit on consumables is typically the status quo. efficient production operation. However, when it comes to the welding process, taking a hit on consumables is typically the status quo.

Stick electrodes were developed around 100 years ago and are still among the most commonly used consumables in the field of welding. Spooled wire is also an essential consumable in welding operations. With multiple consumable options to choose from, it’s key for business owners to consider which method would best meet their needs. Furthermore, it’s important to look at the hurdles associated with cutting back on costs related to consumables.

Common Jobs for Stick Electrodes

Most unsophisticated welding jobs typically attract the stick electrode method of welding. Ornamental wire, fences, bars, gates – all are stick electrode-friendly jobs that are economical, especially in developing countries or in markets where there is an abundance of transformer-type welders. Stick-friendly metals include cast iron, mild steel, low-alloy steel and stainless steel.

Read more...

|

Winter Weather – Plan. Equip. Train.

To Prevent injuries, illnesses, and fatalities during winter storms.

Preventing Slips on Snow and Ice

To prevent slips, trips, and falls, employers should clear snow and ice from walking surfaces, and spread deicer, as quickly as possible after a winter storm. When walking on snow or ice is unavoidable workers should be trained to:

- Wear footwear that has good traction and insulation (e.g. insulated and water resistant boots or rubber over-shoes with good rubber treads)

- Take short steps and walk at a slower pace to react quickly to changes in traction

Preventing Falls When Removing Snow from Rooftops and Other Elevated Surfaces

OSHA’s Hazard Alert* and winter weather webpages provide guidance to employers on how to prevent serious injuries and fatalities. Employers should consider options to avoid working on roofs or elevated heights, plan ahead for safe snow removal and must:

- Provide required fall protection and training when working on the roof or elevated heights

- Ensure ladders are used safely (e.g. clearing snow and ice from surfaces)

- Use extreme caution when working near power lines

- Prevent harmful exposure to cold temperatures and physical exertion

Read More...

|

How to Photograph Art

Or Just About Anything Else

If your art involves color, shape, dimension or texture, direct sunlight is the best light source, and it is widely available on this planet. Not talking about full — or open — shade (illuminated by the overly blue sky above), not dappled light (like from a tree's varying shadows), not overcast sky light (when the sun goes behind a cloud), but direct light beamed down 93 million miles from our local star. is the best light source, and it is widely available on this planet. Not talking about full — or open — shade (illuminated by the overly blue sky above), not dappled light (like from a tree's varying shadows), not overcast sky light (when the sun goes behind a cloud), but direct light beamed down 93 million miles from our local star.

Direct sunlight, however, is not always available, and other natural and unnatural light sources have their qualities, too. (See Other Light, below.) They're just not as good nor cheap nor easy to deal with as the light from the sun.

Learn More!

|

|

| |

|