NOMMA's Industry Event of the Year is Next Week!

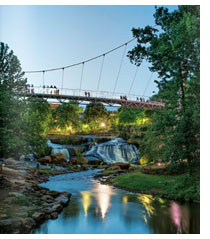

NOMMA's 58th Annual Meeting will be held next week from March 16-19 in Greenville, South Carolina. With invaluable education sessions, live demonstrations, vendor exhibits, a shop visit, the Top Job awards contest, and so much more, you won't want to miss it!

There will be lots to do when you're not attending sessions, networking with fellow friends in the industry, or watching one of the live demonstrations. If you'd like to plan some things to do and sights to see, visit www.visitgreenvillesc.com for some tips.

We hope to see you in South Carolina next week!

The January/February Issue of O&MM Fabricator will be at METALfab2016!

While the March/April issue is getting ready to hit the press, read past issues of O&MM Fabricator for great business tips, various articles on fabricating techniques, and to learn about new products in the market! While the March/April issue is getting ready to hit the press, read past issues of O&MM Fabricator for great business tips, various articles on fabricating techniques, and to learn about new products in the market!

You can expect to see articles on efficient and cost-effective sandblasting methods, an exploration of the various forging methods, metal sculptures in the landscape, tips to lead and empower your employees and so much more in the March/April issue! Check out the articles from fellow NOMMA members Albina Co. and Ryan Calloway with Creative Iron Works in the upcoming issue as well.

As always, we'd like to thank the advertisers for their continued support of the magazine, because without them this magazine wouldn't be possible. If you'd like to get information on advertising in future issues of O&MM Fabricator, you can contact the publication director, Beth Palmer, by calling her at 352-333-3404 or by emailing bpalmer@naylor.com.

|

Register Now for the 2016 ABANA Salt Lake City Conference!

The 2016 ABANA Salt Lake City Conference will be held in Salt Lake City, Utah at the Utah State Fairpark from July 13-16. There will be demos of architectural and sculptural blacksmithing,

foldforming, and more. There will also be teaching tents with hands-on participation with the demonstrators, professional seminars, a fine art gallery with an auction, a marketplace, and so much more!

Reserve your hotel now and pay later! There will also be on-site camping available.

|

Do You Want to be in the Next Issue of O&MM Fabricator?

If you do, be sure to reach out to O&MM Fabricator editor, Marbella Miller. We love to feature industry news, updates, tips, etc. from our members and friends in the industry in both the O&MM Fabricator and in the NOMMA Newswire eNewsletter. You can reach Marbella directly by emailing her at marbella@naylor.com or by calling her at 352-333-3391. If you do, be sure to reach out to O&MM Fabricator editor, Marbella Miller. We love to feature industry news, updates, tips, etc. from our members and friends in the industry in both the O&MM Fabricator and in the NOMMA Newswire eNewsletter. You can reach Marbella directly by emailing her at marbella@naylor.com or by calling her at 352-333-3391.

|

Structures

In order to be placed in this category, the structural fabrications should include (but not be limited to) structural steel, bridges, canopies, gazebos, trellises, entry arches, sunshades, and cladding.

Gold Winner:

Migala Metal Designs

Harvard, Illinois

This job was designed by the architecture firm and was part of a complete rebuild of an 11th floor penthouse apartment. It involved creating 22 custom I-beams located on both sides of the exterior terrace. The longest are 13-1/2' and weigh about 280 lbs. The shorter verticals are about 8' long. Each I-beam contained a 1/2" wide waterjet pattern sandwiched between four pieces of 3" angle iron. C-channel was bolted to the wall and the beams were bolted and welded to it. The finish is powder coated Statuary Bronze. Some of the challenges included getting the beams to the jobsite and bringing them up the freight elevator - one at a time. Much planning was involved to assemble the pieces on the edge of the 11th floor. The vertical beams had to be raised in space and secured while leaning against the short wall. A pallet jack was used to hoist the verticals in place, and lots of safety equipment was involved in the process.

Silver Winner:

MDO Welding & Fab. Inc.

Wheaton, Illinois

This canopy structure was designed by the architect in collaboration with the MDO Welding & Fab. Inc. shop and was modeled after early 1900s French metro station canopies. The canopy is fabricated out of steel and measures just under 12’ height, with a 12’ wingspan, and is over 16’ long. All of the scroll work was completely hand forged/scrolled, and the base shoes were hand made from plate steel with a layered panel design. The structure was finished in oil-rubbed, bronze, textured powdercoat. The biggest challenge was that the wings of the canopy are not only curved, but they also have a setback of about 14" to give the canvas a bigger shadow profile and more appealing shape since it was designed to shade the bar and grill, given where the sun travels in relation to their house and canopy. It was a challenge to make sure each wing had the perfect angle to then fit the canopy canvas tight and without wrinkles. Install was done by the MDO Welding & Fab. Inc. shop. This canopy structure was designed by the architect in collaboration with the MDO Welding & Fab. Inc. shop and was modeled after early 1900s French metro station canopies. The canopy is fabricated out of steel and measures just under 12’ height, with a 12’ wingspan, and is over 16’ long. All of the scroll work was completely hand forged/scrolled, and the base shoes were hand made from plate steel with a layered panel design. The structure was finished in oil-rubbed, bronze, textured powdercoat. The biggest challenge was that the wings of the canopy are not only curved, but they also have a setback of about 14" to give the canvas a bigger shadow profile and more appealing shape since it was designed to shade the bar and grill, given where the sun travels in relation to their house and canopy. It was a challenge to make sure each wing had the perfect angle to then fit the canopy canvas tight and without wrinkles. Install was done by the MDO Welding & Fab. Inc. shop.

It took approximately 100 hours to complete this project.

Bronze Winner:

Big D Metalworks

Dallas, Texas

Big D Metalworks created a Trellis structure with custom triangular stainless steel supports with 1/2" diameter curved stainless steel rods. This project was an existing Arboretum that added 8 acres of new property to its existing facilities. Big D Metalworks' scope of work included 214 lineal feet of continuous stainless steel trellis with six different raddi. All of the triangular supports were fabricated from 1/2" thick 316 alloy stainless steel plate. The 53 triangle supports all vary in size with no two supports being the same. Each support is projecting off of the face of the building at a different angle. The 3/4" diameter rods were pre-rolled and finished in the shop and sent to the field where they were welded on to the top of the triangle supports. The final structure was finished with an angel hair (nondirectional) finish.

It took approximately 959 hours of labor time to complete the work (200 hours fabrication, 217 hours finishing, 542 hours installation).

|

Some know Thomas Berry as a wealth of slogans, maxims, tidbits of advice. A St. Paul trove of oft-times unsolicited tips on how to live life and make it in business.

And by Berry’s standards, he made it.

His business, the Selby Ornamental Iron Co. on St. Paul’s East Side, has weathered 62 years worth of bad economies and shifting trends. Berry has watched plenty of competitors in the ornamental iron trade — fencing, railing and decorative work — fold, from a couple dozen down to a handful today.

|

|

CMD Releases Quarterly Forecast Report Revealing U.S. Construction Slightly Underperformed in 2015, but Growth Lies Ahead in 2016

According to the report, the demand for single-family homes will exceed the demand for multi-family homes and drive the performance of residential starts over the next several years. Additionally, industrial starts, which increased greatly in 2014 and 2015, will be blunted by depreciation in the U.S. dollar. Medical starts, which increased 8.6 percent in 2016, will settle around 5.0 percent annual growth from 2017 to 2020 as they ride the crest of an aging population.

|

*Editorial Disclaimer: Although this article's focus is on stone fabrication, the advice given can be extended to all kinds of fabricators.

The easiest way to alleviate potential bodily damage is to invest in material handling systems, which are just as important to the fabrication process as those saws and CNCs. If you are considering a new machinery purchase, it pays to do your due diligence on identifying your production issues. In many cases, the bottlenecks are better solved by improving workflow conditions than simply just adding another machine, usually at a fraction of the cost. Without proper handling systems, like cranes, vacuum lifters and installation carts, "manhandling" stone all day long not only slows production, but will have eventual detrimental effects to you and your employees, resulting in time loss, chronic pain and workers comp claims. The easiest way to alleviate potential bodily damage is to invest in material handling systems, which are just as important to the fabrication process as those saws and CNCs. If you are considering a new machinery purchase, it pays to do your due diligence on identifying your production issues. In many cases, the bottlenecks are better solved by improving workflow conditions than simply just adding another machine, usually at a fraction of the cost. Without proper handling systems, like cranes, vacuum lifters and installation carts, "manhandling" stone all day long not only slows production, but will have eventual detrimental effects to you and your employees, resulting in time loss, chronic pain and workers comp claims.

Learn More...

|

|

This article from Gate Depot offers advice for the following gate operations:

- Lubricating Sealed Bearings on Driveway Gates

- Garden & Driveway Gate Block Pin Hinge Lubrication

- Slide Gate Chain Lubrication & Tensioner Adjustment

- Swing Arm Gate Operators

- Battery Models

- Solar Panel & Battery Maintenance

- Safety Equipment Maintenance

"You can add years of life to your driveway gate & gate automation equipment with simple annual maintenance."

|

|

| |

|