Exploring Stair Shops and Facilities Across Our Nation, First Stop...Heirloom Stair and Iron

View both wood and iron fabrications and expert demonstrations. Originally just woodworkers, Heirloom learned to incorporate iron and other metals into their product to meet customer demand. Learn about their successful model of growth and focus on design while networking with industry professionals from markets across the country. Attend morning/afternoon seminars and exhibits.

NOMMA members may register at the SMA member price by entering code: RECIP160624

|

Early Bird Registration Ends November 1

When: Friday, November 11, 2016, 8 a.m. - 3:30 p.m.

Where: Art's Work Unlimited, Miami, Florida

Contact & RSVP: 888-516-8585, ext. 102 or REGISTER ONLINE

Program: Demos by the Art's Work staff plus business sessions (details to come)

Details: Breakfast and Lunch provided

Cost: Early bird rate: $89 for NOMMA Members | $139 for Non-Members

REGISTER NOW | LODGING | DETAILS

|

When: Saturday, July 9, 2016

Where: Shrock Fabrication, 229 Maple Ave., Bird-in-Hand, PA 17505

Contact & RSVP: Kendall Shrock, 717-397-9500, kendall@shrockfab.com

Program: Demos on CNC equipment, core drilling comparisons, CD drawing demo, Fronius welding demo, shop tour installation truck show, and more!

RSVP Online | See Complete Details (including lodging!)

|

When: October 14-15, 2016

Where: Lawler Foundry, Birmingham, AL

What: Eight education sessions, vendor show, Friday night dinner, Saturday breakfast & lunch

Demos Include: Scroll theory, patinas, roll forming, forging

Top Name Vendors to Date: Walter, Eagle Bending, Glider's Paste, GSS Machinery, Suhner Mfg., Hilti, Sculpt Nouveau

Cost: $200 for NOMMA Members | $300 for Non-Members

RSVP & Register: Martha Pennington, 888-516-8585 ext. 104, martha@nomma.org

Download the Flier (Includes Lodging Info)

|

Where: Stratford Gate Systems (Hebo North America Training Center) - 12318 SE Capps Rd, Clackamas, OR 97015

What: Refresher course for Hebo training and advanced techniques as well as networking opportunities with others in your industry!

Dinner: BBQ will be catered

RSVP & Contact Info: Chris, 503-722-7700, vern@drivewaygates.com

View the Flier Here

|

David Busarello is the new chair of NOMMA’s Membership Development Committee and will serve during the 2016-17 year. The announcement was made by NOMMA president Keith Majka.

"David is one of our top member recruiters and a super enthusiastic member." said Keith Majka. "Better yet, he has experience serving with other nonprofit organizations, which he will bring to NOMMA."

David, owner of Bridgeton Drafting Company (BDC) in Franklinville, New Jersey, started his career as a teenager in his father’s sheet metal shop. He has been in the steel business since 1978, working for a mid-sized structural fabricator and a small miscellaneous shop, before buying BDC in 2000. David is a member of the AISC & NISD in addition to NOMMA. He also serves on NOMMA’s Technical and Accreditation committees. In addition, he has written articles for O&MM Fabricator magazine.

In his new role, David will chair one of NOMMA’s most important committees. In his post, he will not only lead membership efforts, but he will serve as a cheerleader and coach for NOMMA’s member-get-a-member campaign.

|

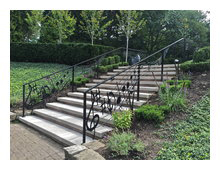

Exterior Railings & Fences (Non-Forged)

All railings and fences including custom castings and cold forged elements with less than 5% custom hand forgings are placed in this category.

Gold Winner:

Finelli Architectural Iron & Stairs

Solon, Ohio

The Fabricator was the designer of this project. This railing was fabricated for Finelli Architectural Iron & Stairs' client’s orchestral-themed garden and is a tribute to her late husband. The nonnegotiable requirement was that the rail had to contain the lyric line from their favorite song, "It Had To Be You." The Finelli team was given freedom of expression within the confines of functionality and were able to get whimsical with the design. They created movement expressed through perspective by weaving the lines in and out of the posts leading the visitor up to the garden. After acquiring actual sheet music, the notes were then cut with a waterjet. The music lines were cold rolled and heat formed, and the split posts replicate the music score. Complexities were created through the offset weaving and wrapping of the ½" round bar. Even though the Finelli team used a full size plot, the bench work was difficult. Transitioning from stair to pitched sidewalk rails also added a level of difficulty. All the material was sandblasted, zinc metalized, and finish painted with an exterior enamel.

This project took approximately 190 hours.

Silver Winner:

A2 Fabrication Inc.

Portland, OR

This railing project was designed by an architect. For 1020 LF. #4 Stainless Steel. All material used was 316 stainless steel. To achieve the end stanchions, two vertical plates per stanchion were used - 3/4"" tapered x 50"" high. To achieve the intermediate stanchions, 2 vertical plates per stanchion were used - 5/8"" thick, tapered. For the base plates, PL3/4"" for the Top Rail, and for the Grip Rail: 1 1/2"" sch 40 pipe. For the Grip Rail Brackets: Saddles = formed plated1/4"", arms = FB 1/2 x 1 1/2 Cables: 1/2"" dia, SS 304; Approximately 280 individual cables at 50' long.

This project took approximately 1,993 hours.

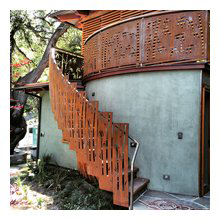

Bronze Winner:

Chapala Iron & Mfg. Co.

Ventura, CA

The designer for this project was the architect. The finish was Soda Blasted CORTEN + West Coast Elements "1/4"" ,3/8"", 11 GA, CORTEN steel with 1/8"x1-1/4"x1-1/4" posts and IPE wood top rail; 1-1/2"" pipe handrail, 1/2" round solid handrail bracket returns 3/8" square head bolts 3/8"" square head lags. For the guard rail; The Chapala Iron & Mfg. Co. team made a template of the curves and brought the frames back to the shop, measured off the frames, and plasma cut 11GA CORTEN sheets 36" high using in-house generated DXF files. From there, the sheets were plate-rolled to match the curve and fastened using 3/8" squarehead bolts to the frame. Install was simple for the team. They screwed into the deck with 3/8"" square head lags. For the stair rail, they plasma cut 11 pieces of 1/4"" CORTEN plate put a slight roll on them from top to bottom and field welded them on the bottom 6" to a T that was formed during manufacturing of the stair treads. The team then templated a pipe handrail and field welded a bracket on to the back of each CORTEN panel. This added rigidity and was necessary to pass inspection.

This project took approximately 64 hours.

|

The Obama administration unveiled the final version of a long-awaited and controversial rule to extend overtime pay to 4.2 million U.S. workers, which marks one of the administration's most significant moves to address stagnant wages.

The rule, which has drawn intense criticism from business groups and Republicans, doubles the maximum annual income a salaried worker can earn and still be automatically eligible for overtime pay from $23,660 to $47,476 and requires that threshold to be updated every three years. It takes effect Dec. 1.

Officials said many workers will earn more money, an estimated total of $12 billion over the next decade, while others will work fewer hours for the same pay.

|

|

Hess Ornamental Iron is part of a diverse crafts industry in York County which includes everything from craft beer to handmade furniture.

The company, which is owned by Scott Hess and Lori Hess, his wife, has made a lot of changes the past few years. It's added employees, moved from Dallastown to larger quarters in Red Lion, and expanded beyond Baltimore, doing an increasing amount of business in the Baltimore, Philadelphia and Washington, D.C. areas.

That includes making the railings for a building on Penn State's Mont Alto campus in Franklin County and winning a job for the National Institutes of Health. Hess Ornamental is restoring 100 feet of wrought iron railing for a building on NIH's campus in Bethesda, Maryland. The railing dates back to the late 1800s or early 1900s.

|

It doesn’t matter how mind-bogglingly fast upstream processes are if it takes forever and a day for parts to make it through the grinding department.

Eight tips for effective grinding - TheFabricator.com

In this business, grinding is where the rubber hits the road, or more precisely, where the grain hits the metal. At every process upstream, most precision sheet metal fabricators employ at least some level of automation. But there’s no getting around it: Grinding down a weld on a formed workpiece is and probably will remain an intensely manual operation.

The act of grinding can be deceivingly simple. But the devil’s in the details. Effective grinding requires operators to apply enough pressure at the correct angle to let the grains—the "cutting tool" of a grinding disc—remove the most metal in the shortest time, while not prematurely wearing the disc or burning out the grinding tool.

|

|

Metal fabrication is essentially the process of manipulating and building metal structures and includes an overlapping variety of specialties, including blacksmithing, ironwork, boilermakers, and more. If you are considering breaking into the steel metal fabrication industry or want to create additional success for an existing company, here are five tips to consider for economic achievement.

|

|

| |

|