NEF NEWS - Octoberfest Continuing Education & Vendor Showcase NEF NEWS - Octoberfest Continuing Education & Vendor Showcase

You Won't Want to Miss This Two-Day Workshop! Make Sure You Register TODAY!

When:

Friday, October 14 through Saturday, October 15

Host & Location:

Lawler Foundry Corp.

4908 Powell Ave S

Birmingham, Alabama 35222

Instructors Include: Roger Carlsen on Scrolls, John McLellan on Forge, Eagle Bending on Roll Forming, and Sculpt Nouveau on Patinas

Hands on Vendors Include: Walter Abrasives, Gilders Paste, Suhner Manuf, Hilti, Sculpt Nouveau, Eagle Bending, GSS Machinery, and FabCAD.

Cost: $200 NOMMA members, $300 nonmembers

Includes: 8 education sessions, vendor showcase, Friday dinner, Saturday breakfast and lunch

Class Schedule:

Friday, October 14

1:00 - 5:00 pm - Vendor Showcase - Hands on demo opportunities

5:00 - 8:00 pm - Dinner - Networking - Casting Pour

Saturday, October 15

7:00 - 8:00 am - Breakfast with the Vendors

9:15 - 10:30 am - Session 1: Class - Scroll Theory

10:30 - 11:45 am- Session 2: Demo - Scroll Theory

11:45 am - 12:15 pm - Session 3: Class - Patinas

12:15 - 1:30 pm - Session 4: Demo - Patinas

1:30 - 2:45 pm - Session 5: Class - Roll Forming

2:45 - 4:00 pm - Session 6: Demo - Roll Forming

4:00 - 5:15 pm - Session 7: Class - Forging

5:15 - 6:30 pm - Session 8: Demo - Forging

To Register: Contact Martha Pennington (martha@nomma.org, 888-516-8585, ext. 104)

CLICK HERE TO DOWNLOAD FLIER & REGISTRATION FORM

|

Save the Dates: Upper Midwest Chapter

Fall Meeting

When: October 29, 2016

Where: Migala Metals, Harvard, Illinois

Note: Friday evening social

Winter Meeting

When: December 10, 2016

Where: MDO Welding & Fab, West Chicago, Illinois

Note: Work on auction items

Note: Elections are coming up. Rise to the challenge and become a leader of this great chapter.

|

Early Registration Closes September 6 - Register Now and Save!

United Rockland Stairs (URS) is a longstanding, multi-generational company that has continued to evolve and grow within the competitive stairbuilding market. A company with methods and processes steeped in history and tempered with the latest technology. Staunch supporters of the SMA for some 20 years or more, URS has been significant in providing key leaders of our organization who have given countless hours to improve our association and our industry.

Whether at the helm, minding the purse strings, strategizing code reform, or developing quality standards - United Rockland Stairs has done their part. How does participating in the SMA provide a step-up among stiff competition? Come to the workshop and ask!

When:

September 30, 2016

8:00 a.m. - 3:30 p.m. (Breakfast and lunch included)

Location:

Suffern, New York

**NOMMA members get a discounted rate!

|

Thank YOU for Helping NOMMA Increase Its Membership!

NOMMA's June 30, 2016 membership year ended with 527 members, which is a 2% growth rate. This is the first time in a decade that NOMMA has seen an increase in membership.

In 2000, Ed Mack and Joe Romeo led the NOMMA Membership Committee, and they did a great job getting NOMMA to the magic number of 1,000 members. For six years, that number remained stagnant until it began to drop in 2006. Ten years later, membership numbers are picking up. NOMMA's executive director, Todd Daniel, attributes the success of their growth to the Member-Get-A-Member Campaign and to the membership ads placed in the O&MM Fabricator magazine. These two avenues will be the primary focus for the next membership year.

If you want to help the NOMMA Membership Development Team in their efforts to continue growing membership, contact Todd Daniel at the NOMMA office (888-516-8585, ext. 102; todd@nomma.org).

|

Advertising Opportunities in NOMMA's 2017 Membership Directory Will Be Available Soon

As we approach the end of August, advertising opportunities are expected to begin. Thank you to our existing advertisers for supporting the O&MM Fabricator, the NOMMA Newswire eNewsletter, and the upcoming Membership Directory. These publications rely heavily on advertiser support, so we thank those who have already contributed.

If you are interested in advertising and would like to participate in the support of our industry publications, please contact publication director, Beth Palmer, by calling her at 352-333-3404 or by emailing bpalmer@naylor.com.

|

Interior Railings - Nonferrous, Nonforged

All railings including custom castings and cold forged elements with less than 5% custom hand forgings

Gold Winner:

Klahm & Sons Inc.

Ocala, Florida

These interior railings were placed in a three-story townhouse. The railing is made of aluminum with a contemporary bronze cap rail and 3/4" brass balls. At the beginning of each stair there is a large forged tapered lambs tongue. The oval design is made of 3/8" x 3/4" flat bar. The diagonal rods are pierced through the flat bar. Custom aluminum cast collars contribute to the contemporary design. All of the vertical pickets were run through a special dye on the embossing machine. The bronze has an oil rubbed finish. The main body of the railing has a gunmetal finish with Micah added to enhance blues, green, and other colors unlike Silver metallic paint. The decorative element was painted an aluminum color with four coats of transparent gold.

This project took approximately 800 hours.

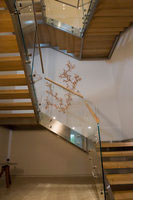

Silver Winner:

Art's Work Unlimited

Miami, Florida

This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads. This was a challenging job for the Art's Work Unlimited team, because this team doesn't do a lot of complete large stairs. In this case, the architect wanted the stringers to be stainless tubing with a sharp corner, not radiused. Since this stair encompassed three flights with the double stringer, the Art's Work Unlimited team found a facility to laser weld the 2" x l0" x 1/4" stainless tubes. It was a pretty tricky layout due to the variations in floor-to-floor on the three levels. It was also a tight area to work with. Not to mention, this installation was done in a finished condominium. The Art's Work Unlimited team made wood templates for each piece of glass to give to their glass supplier, and they predrilled welded in 1/2" pre-tapped plugs for the mounting points so that their glass install could go smoothly. Many hours were spent putting the finish on the stainless since it was furnished to us in mill finish. The finish was satin, and the materials used were 304 stainless with mill finish, 9/16" tempered glass, and Oak treads.

This project took approximately 376 hours.

Bronze Winner:

Upright Iron Works Inc.

Griffith, Indiana

These railings were installed in a British school in Chicago, Illinois. They were fabricated on three stairs and were designed by the architect on the project. Two of the three stairs went up two floors with a total of four runs. The other stair went up three floors, which had six runs. The main framework was fabricated with carbon steel pipe: 1 ½" sch 40 pipe for the top bar and 1 ¼" sch 80 pipe for the posts. The rest of the railing was stainless steel: frame ¼" x 1" stainless steel flat bar, 1 ½" x 3/8" opening "U" edging and Banker Wire L-62, ¼" thick wire mesh with 2" centers. All stainless steel had a polished #4 finish.

This project took approximately 1,048 shop hours.

|

"I wanted to provide access to these tools, but with proper and practical instruction on how to use them correctly and safely. I wanted a place that teaches the most state-of-the-art manufacturing techniques, not just traditional shop skills. I wanted to teach these important skills without the bureaucracy of academia because many more Americans should have the same opportunity to innovate, collaborate, learn, and create their dreams."

He started what has become the Vocademy program in the shop he had built behind his house and started teaching machining skills evenings and on weekends. In 2012, he moved into an office building with the equipment he had and funded Vocademy with his own life savings. Since then, he has been able to increase their equipment by forming partnerships with equipment manufacturers to get equipment at low or no cost.

|

|

Defining and Delimiting the Exemptions for Executive, Administrative, Professional, Outside Sales and Computer Employees under the Fair Labor Standards Act

On May 18, 2016, President Obama and Secretary Perez announced the publication of the Department of Labor’s final rule updating the overtime regulations, which will automatically extend overtime pay protections to over 4 million workers within the first year of implementation. This long-awaited update will result in a meaningful boost to many workers’ wallets, and will go a long way toward realizing President Obama’s commitment to ensuring every worker is compensated fairly for their hard work.

|

|

Procrastination comes in many disguises. We might resolve to tackle a task, but find endless reasons to defer it. We might prioritize things we can readily tick off our to-do list—answering emails, say—while leaving the big, complex stuff untouched for another day. We can look and feel busy, while artfully avoiding the tasks that really matter. And when we look at those rolling, long-untouched items at the bottom of our to-do list, we can’t help but feel a little disappointed in ourselves.

The problem is our brains are programmed to procrastinate. In general, we all tend to struggle with tasks that promise future upside in return for efforts we take now. That’s because it’s easier for our brains to process concrete rather than abstract things, and the immediate hassle is very tangible compared with those unknowable, uncertain future benefits. So the short-term effort easily dominates the long-term upside in our minds—an example of something that behavioral scientists call present bias.

|

|

When Chris Cramer started his mobile fabrication and repair business, Metal Connections of Oshkosh, Wisconsin, he worked out of a trailer and used one of Wisconsin’s park-and-ride lots as home base. Today, Cramer has a strong customer base of about 150 businesses, which range from aerospace companies to paper mills and restaurants. While the company has grown greatly in scope and Cramer has traded in the parking lot for a 3,000-ft. fabrication shop, he still does most of his work from his trailer. "I combined all the welding fabrication processes into a mobile service so that I can go almost anywhere and work with virtually any metal, including exotic alloys for the aerospace industry, stainless for restaurants, aluminum and steel."

|

|

| |

|