NOMMA's O&MM Fabricator magazine continues to receive positive feedback! We have a 2017 editorial lineup full of industry-specific material to help professionals in the metal industry learn and grow; a bonus of one to two business-related articles to assist in various employment practices, building a better clientele, how to have a healthy work/life balance, and so much more! NOMMA's O&MM Fabricator magazine continues to receive positive feedback! We have a 2017 editorial lineup full of industry-specific material to help professionals in the metal industry learn and grow; a bonus of one to two business-related articles to assist in various employment practices, building a better clientele, how to have a healthy work/life balance, and so much more!

This valuable magazine wouldn't be possible without advertiser support. Our goal is to continue growing each issue so that we can provide more articles, which in turn we hope will benefit you. If you are planning your marketing dollars for 2017, consider supporting

NOMMA and its publications by purchasing an ad. Not only will you be getting great exposure for your company, you'll be contributing to the success of NOMMA's national publications.

Act now to secure your spot by contacting publication director, Beth Palmer, for advertising opportunities. You can reach her by calling 352-333-3404 or by emailing bpalmer@naylor.com.

|

Only 83 Days Until METALfab & FENCETECH 2017!

Whether you’re an exhibitor or attendee, the upcoming FENCETECH & METALfab 2017 conference has something for everyone. Join your peers from across the country in the largest gathering of the fence and ornamental and miscellaneous metals industries for FIVE full days of industry expertise.

Here’s what’s in store:

• Education related to today’s technology

• Business tools, sales tips and training

• Certification and networking opportunities

• Expected attendance of 4,800

• Over 300 booths on the exhibit floor

• History in the Making Opening Party

• Annual Meeting/General Session

Schedule of events:

NOMMA’s METALfab: click here

AFA’s FENCETECH: click here

|

November 18 is the deadline for Top Job award applications!

2017 Contest Deadlines & Fees:

Early Bird (Aug. 31) - $55

Regular Fee (Nov. 18) - $80

Late Fee (Dec. 21) - $130

|

D&D Technologies announces the acquisition of SHUT IT® Gate Hardware, the manufacturer of BadAss® hinges. The acquisition provides D&D additional product lines of wheels and steel hinges to complement its current magnetic safety latches, hydraulic closers, aluminum and polymer product portfolio.

|

|

If you do, please be sure to share this information with NOMMA's editor, Marbella Miller. We love to feature news, updates, tips, etc. from our members and friends in the industry in both the O&MM Fabricator and in the NOMMA Newswire eNewsletter. You can reach Marbella directly by emailing her at marbella@naylor.com.

|

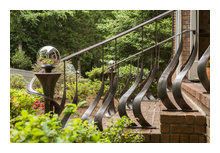

Exterior Railings & Fences - Forged

This category includes all railings and fences containing custom hand forged elements.

Gold Winner:

The Heirloom Companies

Campobello, South Carolina

This client was very eclectic in her taste. She wanted a unique railing on the block. She provided a little direction in design, but The Heirloom Companies team interpreted the client's wishes as something that leaned more toward fantasy. This client was very eclectic in her taste. She wanted a unique railing on the block. She provided a little direction in design, but The Heirloom Companies team interpreted the client's wishes as something that leaned more toward fantasy.

Aluminum was the material used. After cutting out the basic shapes, the team went to work cold forging and shaping them into the flowing shapes seen in the photo. The newels were intended to look as though they were growing out of the ground. A 4"pipe was used to start the newel fabrication process and then layers of flat plate were applied to give it an organic look. An acid based patina was applied for an earth tone color.

This project took approximately 175 hours.

Silver Winner:

Berryhill Ornamental Iron LLC

Broken Arrow, Oklahoma

This project was designed by the fabricator. The finish was a base powder coated black (hand rubbed glaze of PPG industrial automotive paint, bronze color was made for the Berryhill Ornamental Iron team). A "3" solid round bar, 2" solid round bar, 3/4" solid round bar, 5/8" solid round bar, 1/2" solid round bar, 1-1/4" x 1/4" flat bar, and 6" x 1/4" flat bar. There was approximately 300' of deck and stair railings on two separate areas at the client's lake home. All materials were power hammered, textured and drawn. All branch material was welded and ground for natural detail. The post design was created to give a bunched and banded branch effect. Middle section supports hammered from 3" solid stock to create a new trunk look. The client requested that all branches be terminated to prevent animal and child issues. The biggest challenge this team had was the 3.5 hr distance from shop for measuring and installation, as well as both decks and staircases, were torn out and rebuilt during the project.

This project took approximately 2,230 hours.

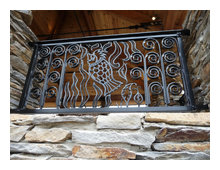

Bronze Winner:

Lynda Metcalfe Designs

Brasstown, North Carolina

Eleven panels of approximately 20" x 40" mild steel, with a mixture of heavily forged elements, traditional joinery, welding and laser cut parts. The figurative features in the panels were designed primarily by the landscape architect while the fabricator supplied design input for the scroll sections. The main challenge was to achieve as much of a three-dimensional feel as possible and keep the cartoon feel of the figures. The fabricator, Lynda Metcalfe, achieved this by laser cutting select elements using different stock thicknesses and added forged shaping to some elements. Another challenge was that the framework for the railing panels had to be installed early in the build process of the keep structure while the decorative panels were being worked on in several months time. The panels were framed in solid 1" square bar to help prevent warpage and bolted directly to the underside of the cap rail with brackets and to side brackets in the columns.

|

Detrimental Elements: Importance of Removing Detrimental Weld Filler Elements from the Weld Prior to Coating

Formation of the proper pretreatment conversion coating and adhesion of subsequent coatings to welds is influenced by the cleanliness of the weld area. The welding process can create various inorganic soils depending on the welding process utilized. These inorganic soils must be removed to ensure the success of the pretreatment conversion and subsequent coating operations.

This article provides information on the weld filler elements found in the weld that are detrimental to coating adhesion and also presents the recommended method of removal for these soils.

|

Most business owners need to get up to speed. In just a few weeks, big changes are  coming to the way small businesses calculate overtime for their salaried workers.

Starting Dec. 1, the salary threshold for overtime that’s been in place since 2004 will nearly double to $47,476, and it will continue to rise every three years per new regulations approved by the Department of Labor (DOL) in May. That means any employee who earns under that amount will be owed overtime, or time-and-a-half, for working more than 40 hours a week. The move is likely to increase wages and earnings for some 4.2 million workers, according to the DOL.

|

Take advantage of holiday parties to make new friends and grow your network, which in turn will lead to growing your business.

The tips [in this article] make this easy.

|

|

Saying yes to customer requests you can't fulfill might end up costing you more in the long run.

While it's tempting to never turn away business (or an out-of-scope request from a customer), you know what's best for your company. And that means turning people down sometimes, particularly if meeting their demand will drain resources and time you can't afford to spend.

That's why [Inc. magazine] asked several founders from Young Entrepreneur Council (YEC) how to deliver a firm, polite 'no'--without severing the relationship completely.

|

|

| |

|