| Past Issues | Subscribe | Print Friendly | NOMMA.org |

|

NOMMA News & Events

Member News

Featured Past Top Job Contest Winner

Gold: Anderson IronworksTitle of Entry: Pediment and Capitol Restoration

When it comes to restoration, Anderson Ironworks prides itself on its ability to emulate the craftsmanship of the master blacksmiths of the past while incorporating modern techniques to arrest future corrosion and failure of metalwork they restore. The company's award-winning restoration project for Princeton University is one recent example of the team's incredible abilibites. Originally built in 1911, in the early 1990s the pediment and column capitals of this historic structure were removed and scrapped due to deterioration. Most restorations have remnants to work from to create new components, but in this case, nothing was left. Anderson Ironworks had to design everything from photos, which was a challenge, as none of the ornamentation in the existing gate or fence repeated in the pediment and capitals. Once the company had their shop drawings approved, they were printed as full-size templates for their fabricators and smiths to build from. For the acanthus leaves around the base of the capitals, Anderson used clay to model the leaf, had that laser measured, then machined press plates to get the approximately 30 leaves required for the capitals. The group stayed true to the original vision of the building for the restoration, using real wrought iron for ornamentation and mild steel for structural members. Wrought iron was donated in the form of 70 feet of iron fence which was reforged into shapes required for the project. In the end, a full 700 linear feet of bar had to be completely reforged. It was a challenging endeavor, with exceptional results. To learn more about Anderson Ironworks, and to see more of the company’s signature work, visit www.andersonironworks.com.

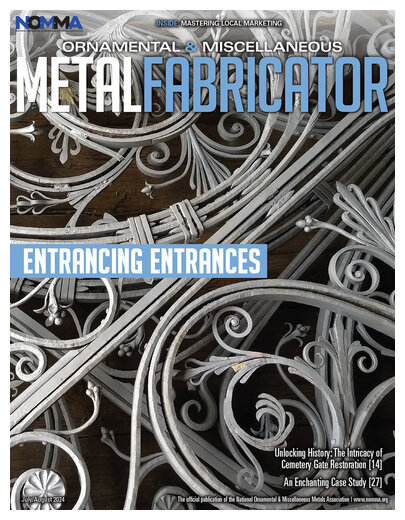

Featured Stories

NOMMA Member Savings Program

|

||||||||||||||||||||||||

Get your company name in front of hundreds of metals industry professionals – sponsor a NOMMA webinar for only $400! Capitalize on targeted exposure: reach a focused audience of industry professionals who are interested in continuing education for themselves and their employees. You get branding on all webinar marketing, a live introduction and video commercial.

Get your company name in front of hundreds of metals industry professionals – sponsor a NOMMA webinar for only $400! Capitalize on targeted exposure: reach a focused audience of industry professionals who are interested in continuing education for themselves and their employees. You get branding on all webinar marketing, a live introduction and video commercial.

NOMMA Upper Midwest Chapter Meeting

NOMMA Upper Midwest Chapter Meeting NOMMA is the ONLY association dedicated to the ornamental and miscellaneous metal fabricator. Our publications serve as a communication tool for advertisers to build and brand their company image within this unique space.

NOMMA is the ONLY association dedicated to the ornamental and miscellaneous metal fabricator. Our publications serve as a communication tool for advertisers to build and brand their company image within this unique space.