View both wood and iron fabrications and expert demonstrations. Originally just woodworkers, Heirloom learned to incorporate iron and other metals into their product to meet customer demand. Learn about their successful model of growth and focus on design while networking with industry professionals from markets across the country. Attend morning/afternoon seminars and exhibits. NOMMA members may register at the SMA member price by entering code: RECIP160624 Visit https://www.naylornetwork.com/nom-nwl/articles/index.asp?aid=377708&issueID=46957 to view the full article online.

|

The National Association of Architectural Metal Manufacturers (NAAMM) announces that its standard ANSI/NAAMM MBG 531 is being revised. It is available for public review and comment. To obtain the document, ballot and other related documents go to http://www.naamm.org/ansi/pending.aspx. Comments must be received on or before June 13, 2016 to be considered. Persons interested in participating with the consensus committee for MBG should contact the NAAMM office or visit the association website at http://www.naamm.org/ansi/consensus.aspx. The National Association of Architectural Metal Manufacturers (NAAMM) announces that its standard ANSI/NAAMM MBG 531 is being revised. It is available for public review and comment. To obtain the document, ballot and other related documents go to http://www.naamm.org/ansi/pending.aspx. Comments must be received on or before June 13, 2016 to be considered. Persons interested in participating with the consensus committee for MBG should contact the NAAMM office or visit the association website at http://www.naamm.org/ansi/consensus.aspx.

|

|

NOMMA Wants YOU to Help Recruit NOMMA Members and Relay the Value of Membership!

NOMMA’s 2016-17 membership drive is underway! Noted business author and speaker Ed Rigsbee kicked off the membership campaign by hosting a webinar on membership recruitment.

Over the next 12 months or so, all NOMMA members are encouraged to sponsor a member. To sponsor a member, simply ask him or her to put your name on the "Sponsored By" line of the membership application. Those who sponsor a member are recognized regularly in the "Iron Club" section of the magazine and in our weekly email blasts. You may also help by submitting a lead to the NOMMA office, which makes you an automatic member of the "Rust-Free Club."

The NOMMA Membership Development Team is currently looking for volunteers to help with the campaign. If you want to help with this effort, contact Todd Daniel at the NOMMA office (888-516-8585, ext. 102; todd@nomma.org).

|

|

Have You Checked Out NOMMA's NEW Online Career Center? Last month NOMMA announced the launch of their new Career Center. It connects metalworking professionals across all disciplines and career stages with employers offering career opportunities, serving as a robust source of up to thousands of job opportunities.

Some of the benefits NOMMA's new online Career Center offers is:

For more information, please visit the NOMMA Career Center.

|

|

|

Furniture and Accessory Fabrication (Non-Forged) In order to be placed in this category, metal fabrication including custom castings and cold forged elements should have less than 5% custom hand forgings. This category includes items such as lighting, tables, chairs, fire screens, fire tools, baker's racks, and window and door grills. Gold Winner: The design of this custom range hood was done by an Architect and was made for a long standing customer of Finelli Architectural Iron & Stairs. The basic frame construction consisted of flat stock with dimples which were created by hitting a ball peen hammer with a sledge hammer to get the desired texture. All of the sheet metal was also peened using the same, old style technique, cut to size, and then welded into place within the frame. The difficulty grew in acquiring the correct radius and angle on the corner pieces of the curved range hood. The Finelli team was able to overcome this obstacle by experimenting with 3D CAD and geometric equations. The 48 rivets were added to the hood and a hammered bar was used for scrollwork as support brackets on each end of the hood. The entire project was wire brushed clean and finished with a clear lacquer.

This project took approximately 85 hours.

Silver Winner: The design of this table was done by the fabricator. The base of the table is 2"x4" stainless steel rectangular tube with a brushed finish. The top of the table is a formed cold rolled steel top with a wood core finished with a black patina. The fabrication of the table top was straight forward. The table was formed with cold rolled steel 16 ga sheet on the press brake to fit around a solid wood core. Table top is 44"W x 108"L x 2" thick. The table base was where the challenge came from. The team fabricated the hollow diamond shaped center of the table from thick plate stainless steel, which sets the angles for the eight legs and is the core to which all of the weight of the table is centered on. Getting the angles perfect so that they could have a tight TIG weld to hold everything together was time consuming because each of the eight legs has compound angle cuts going in three directions to off set from the center line, fit the diamond, and rise or fall to meet the top or floor. The finish: Steel top is finished with black patina and an automotive satin clear coat to seal the metal. The base for table is brushed stainless steel.

This project took approximately 50 hours. Bronze Winner:

This project was a very unique piece that proved to be more of challenge than the team first realized. The stone seating had already been previously installed, and the team working on this project was asked to provide some kind of back rest to bring it all together. They used flat bar which was heated and bent around a form, but given how close the slates were together, in order to get them all to match perfectly caused a bit of frustration. Seven individual stanchions were created for support. This involved cutting the shape out of plate and then bending both an inside and outside piece in order to frame it and give it strength. Attaching the backing they created to the concrete floor and the back of the seat provided exceptional rigidity. A powder coating was used as a finish.

This project took approximately 170 hours.

|

|

|

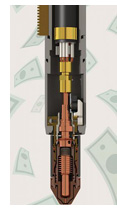

You may be if you aren’t scrutinizing your consumables use During almost every shop visit I hear the same question: "How can I make my business more productive and yet save money?" The answer is simple: Take a look at your consumables.

It’s a common sight on the cutting shop floor: Next to every CNC plasma cutting machine is the 5-gallon pail of "used up" consumables. Mostly copper, these spent consumables eventually find their way to the recycling bin.

Quite often I reach into this bucket and pull out a handful of parts to review. I see the erosion of the electrode and the swirl marks on the nozzle. The condition of the nozzle and shield orifices often tells a story about either the condition of the plasma cutting system itself or of training issues that should be addressed with machine operators. Sometimes as much as 40 percent of the parts in the scrap pail can go right back in the torch, where they can continue to produce parts with excellent cut quality. |

|

When was the last time you wrote or draw something on a piece of paper? Many people think that it is a pointless and ineffective thing to do. However, thousands of graphic designers all over the world always sketch the design of their projects before making it digital. Why would they do it if it was so pointless and ineffective? If you are a graphic designer and you have never tried a pen and paper for work, you may find the reasons for trying in this post. If you are a graphic designer and you do sketch before using a computer, this post can remind you of the reasons you do it. Read on to see 10 advantages of creating web design on paper first. Visit http://gohunters.com/blog/10-reasons-writing-web-design-paper-will-help/ to view the full article online.

|