|

NEF Octoberfest Continuing Ed & Vendor Showcase

Two-day workshop featuring classes and demos. When:

Host & Location: Instructors Include: Roger Carlsen on Scrolls, John McLellan on Forge, Eagle Bending on Roll Forming and Sculpt Nouveau on Patinas. Cost: $200 NOMMA members, $300 nonmembers Includes: 8 education sessions, vendor showcase, Friday dinner, Saturday breakfast and lunch To Register: Contact Martha Pennington (martha@nomma.org, 888-516-8585, ext. 104) |

2016 ABANA Conference is Only Days Away!

The 2016 ABANA Salt Lake City Conference will be held in Salt Lake City, Utah at the Utah State Fairpark from July 13-16. There will be demos of architectural and sculptural blacksmithing, foldforming, and more. There will also be teaching tents with hands-on participation with the demonstrators, professional seminars, a fine art gallery with an auction, a marketplace, and so much more! To find out more, visit abana.org/2016SLC

|

|

Have You Visited NOMMA's Online Career Center? NOMMA recently announced the launch of its new Career Center. It connects metalworking professionals across all disciplines and career stages with employers offering career opportunities, serving as a robust source of up to thousands of job opportunities. Some of the benefits NOMMA's new online Career Center offers is:

For more information, please visit the NOMMA Career Center.

|

|

*Attention NOMMA suppliers: Send us your new product news; we’re happy to share it with the membership. If interested, please email Marbella directly at marbella@naylor.com.

Feeney, Inc., a manufacturer of high quality stainless steel and aluminum railing products, recently announced the introduction of a new powder coat finish for the company’s DesignRail® aluminum railing system. Textured Black adds to Feeney’s extensive color collection by being the first of its finishes to feature a slightly raised, uniformly textured surface. Textured Black is well-suited for interior and exterior applications. It offers a more natural tone, creating a softer color experience. Textured black also helps conceal fingerprints and minor scratches. "This new finish is already creating buzz among our customers," says Andy Penny, vice president of marketing and advertising at Feeney, Inc. "Textured Black is sophisticated, versatile, and a little unique; it’s ideal for both residential and commercial projects as well as modern and traditional design styles." Like all the company’s powder coat finishes, Textured Black, adheres to AAMA-2604 coating specifications for superior impact and weather resistance, and color retention. Textured Black is priced the same as all of Feeney’s standard colors. About Feeney |

|

Want to be featured in O&MM Fabricator or the NOMMA Newswire?

|

|

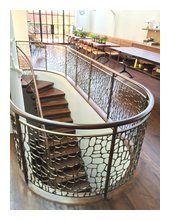

Stairs Complete (Residential) In order to be placed in this category, the majority of the stair must be of metal construction and installed in or on private residence. Gold Winner: The design of the custom stairs was done by an architect. Some of the features included are bronze railings that were antiqued and waxed and wood treads that were stained and sealed. The stair structure, which is hidden in the wall, is made of steel. The railings are bronze, cast and bar stock. There is also cantilevered stair with structural steel stringer in wall. Built-up steel tread assemblies were bolted to in-wall stringer, shimmed, and fully welded. Wood treads were fully shop assembled and slid onto the steel subtreads. The "jali screen" of the guardrail was cast out of bronze from a hand-formed wax mold. In turn, the screen was welded into the guardrail assembly. All fasteners were concealed for a seamless end product. The greatest challenge for this team was achieving the fluid curve of the stair while cantilevering from a single tread. In addition, the custom wood profile for the stair treads was challenging to both fabricate and install.

This project took approximately 3,279 hours.

Silver Winner:

Bronze Winner:

This complete stair system has a single stringer attached at the ground floor and the second floor joist. An architect provided a concept sketch and the steel stringer sizing. Vertical bar brackets were welded to the side of the mono-stringer to support each of the treads. The treads are solid wood beams cut the thickness of the rise of each step and notched to clear the mono-stringer. The treads were stacked one on top of the next at the stair angle with an overlap for attachment. The ¾" round bar balusters were hammered for texture and flattened on the end for side mounting into the solid treads using square headed lag fasteners for an antique look. The natural steel finish was satin clear coated.

This project took approximately 198 hours.

|

The Challenge: Place a 49-foot-long steel bridge over train tracks and onto supports with laser-like precision from a small working area in a residential neighborhood. The Challenge: Place a 49-foot-long steel bridge over train tracks and onto supports with laser-like precision from a small working area in a residential neighborhood.The steel bridge structure was delivered in two sections and welded on-site, resulting in a total weight of 77 tons, including the required slinging gear. After the load was meticulously rigged so that it would be perfectly balanced, the power to the overhead lines was turned off and the precision lifting started.

|

|

Many of today’s cutting applications require surgical-like precision to produce small,

intricate parts. Technological advancements in waterjet and laser cutting are making these processes even more attractive to fabricators in a variety of industries. intricate parts. Technological advancements in waterjet and laser cutting are making these processes even more attractive to fabricators in a variety of industries.Some of the newest innovations to take place in laser and waterjet cutting have focused on the resources required to cut smaller, intricate parts. The potential for product miniaturization is continuing to draw interest, while posing a number of technical challenges. Fortunately, companies have begun to develop new technologies to meet the unique problems posed by micromanufacturing. As the world of small-scale cutting continues to grow larger, waterjet and laser cutting machines could have an even greater impact on the manufacturing industry.

|

|

That’s entertaining, but let’s look at the facts: a 2010 study revealed that the average U.S. employee spends 2.8 hours a week dealing with disputes at work, resulting in losses of $359 Billion across the American economy. In reality, conflict pulls people away from their jobs and kills productivity. Visit http://blog.idonethis.com/handling-workplace-conflict/?utm_source=rss&utm_medium=rss&utm_campaign=handling-workplace-conflict&utm_source=iDoneThis+Blog+Email+List&utm_campaign=890d8d7ca5-RSS_EMAIL_CAMPAIGN&utm_medium=email&utm_term=0_1ddf8bc7af-890d8d7ca5 to view the full article online.

|

NEF NEWS

NEF NEWS

Feeney expands its color options for the company’s DesignRail® aluminum railing line.

Feeney expands its color options for the company’s DesignRail® aluminum railing line. If you do, be sure to reach out to me, Marbella Miller, to submit your material. We love to feature related and current news and updates, tips of the trade, feature stories, new products, etc. from our members and friends in the industry. We welcome articles and information for both

If you do, be sure to reach out to me, Marbella Miller, to submit your material. We love to feature related and current news and updates, tips of the trade, feature stories, new products, etc. from our members and friends in the industry. We welcome articles and information for both