|

||||||||||||

|

||||||||||||

|

Association & Industry News

The RMC Research & Education Foundation has opened registration for this year’s Walk for Wellness. It will again take place as part of NRMCA’s ConcreteWorks 2022 and in conjunction with NRMCA’s National Truck Mixer Driver Championship. The Walk is scheduled for Saturday, October 1, at 8:30 a.m. (check in starts at 8 a.m.). Participants may pre-register from the Walk’s informational page. The registration fee is $25 and is tax deductible as a donation to the Foundation. We had a record number of participants last year and expect to break the record again this year! Sponsorships are also available for this event and is a terrific way to demonstrate your company’s support for the Foundation and the industry. The sponsorship form may be accessed here. Thank you to Lehigh Hanson, Master Builders Solutions and GCP Applied Technologies for their sponsorships of the event. For more information, please contact Foundation Senior Director Jennifer LeFevre at jlefevre@rmc-foundation.org or at 571-235-6247. Add your company's name to the growing list of sponsors for NRMCA’s most exciting event of the year, ConcreteWorks. Enhanced sponsorship opportunities for this event still include the ConcreteWorks Event Mobile App, ConcreteWorks Registration Website, ConcreteWorks Spouse Hospitality Suite and other great opportunities. There are also many great sponsorship options remaining for the National Mixer Driver Champion (NMDC) such as the NMDC Course Challenges, NMDC Driver Position Reception, NMDC Course Tent and many more selections. NRMCA encourages you to circulate these opportunities within your company and help support the ready mixed concrete industry. For more information, contact Jacques Jenkins at jjenkins@nrmca.org or 703-706-4865.

Engineering

NRMCA and the Arkansas Ready Mixed Concrete Association are presenting the one-day course Improving Concrete Quality intended for concrete producers, ingredient material suppliers, engineers, testing labs and contractors on Wednesday, September 14, in Little Rock, AR. Improved concrete quality can benefit all stakeholders in a concrete construction project. This course will address the following:

Course instructors are Kevin MacDonald, Ph.D., FACI, Beton Consulting Engineers LLC, and Karthik Obla, Ph.D., P.E. at NRMCA. Producers will learn readily implementable steps to manage variability and attain a more consistent product; ingredient suppliers will learn how material variation affects concrete variation; engineers will learn how to improve quality through specifications and testing lab professionals will learn to measure and improve testing quality. Upon successful completion of the course, attendees will earn 8 professional development hours, a certificate of completion and credits toward NRMCA’s STEPS program. Click here for more information or contact Karthik Obla at kobla@nrmca.org. The NRMCA Developing Industry Leader (DIL) group is asking for your help in understanding how much the industry spends on returned concrete. It believes this is valuable information for you and the industry. The compiled information will be provided on the Cost of Returned Concrete Calculator on the NRMCA website. The calculator will provide an industry average benchmark. Users will be able to compare handling processes based on industry average costs, allowing them to compare costs to the industry average. Please download and complete the survey by August 15; surveys should be e-mailed to Karthik Obla at kobla@nrmca.org. Data will be used for calculating industry benchmarks. The calculator and the industry benchmarks will be shared with all participants. The Notes column is intended to clarify the questions. Please note that although there are several questions, not all methods for handling returned concrete apply, so only fill out the information that applies to you. For more information, contact Greg Hendrix at ghendrix@calportland.com, Steve Schaef at steve.schaef@mbcc-group.com or Danielle Belchior at danielle.belchior1@vcimentos.com. SEO

NRMCA has named Dean Browning of Holliday Rock and Manatts, Inc. of Brooklyn, IA, as the recipients of its 6th Annual Safety Award. Mr. Browning is the safety director for Holliday Rock, Co., headquartered in Upland, CA. Manatts, Inc is a family-owned ready mixed concrete company that has safety as a core value. Both were named 2022 award recipients for tireless work and commitment of safety leadership in the industry. NRMCA’s Annual Safety Award acknowledges the significant contribution that safe work practices give to the growth and success of individuals and individual companies and the ready mixed concrete industry as a whole. The NRMCA Annual Safety Award is presented to an individual or company whose actions represent the very highest in the advancement of safety in the ready mixed concrete industry. The award program is generously sponsored by the Truck Mixer Manufacturers Bureau (TMMB). NRMCA’s Commitment to Environmental Excellence Awards competition offers producers national recognition for outstanding contributions to protecting the environment and maintaining sound management practice in their operations. The program salutes companies that have not only met, but surpassed governmental compliance measures and demonstrated a commitment to environmental excellence through plant and staff investment. NRMCA member companies producing ready mixed concrete from a fixed plant location in the U.S., its territories or Canada are eligible to enter. Awards will be determined upon individual plant merits. Winning entrants will be honored at the Awards Ceremony at NRMCA‘s ConcreteWorks this October in Aurora, CO. Winners will also be featured in the Winter 2022 edition of NRMCA’s magazine, Concrete InFocus and the trade publication Concrete Products. Entries and photos must be e-mailed to gmullings@nrmca.org by this Friday, July 22. Click here for more information and to download the entry form. Staff contacts are Gary Mullings and Kevin Walgenbach. A recently distributed study by the MIT Concrete Sustainability Hub (CSHub) states that hurricane-resistant construction may be undervalued by billions of dollars annually. Failing to consider neighborhood texture in hurricane-related wind loss models may undervalue stronger construction by over 80 percent. The error is traced to the failure to take into account the density of a neighborhood and how buildings are configured. The arrangement of building shapes and sizes can amplify or reduce the wind load on buildings within a neighborhood. The paper recommends that coastal states enhance their building codes, especially in densely built-up areas, to save dollars and save lives. MIT CSHub researcher Ipek Bensu Manav notes that current building codes do not sufficiently account for texture-induced load amplifications. “It is important that the benefits of resilient design be quantified so that financial incentives - whether lending, insurance or otherwise - can be brought to bear to increase mitigation. Manav’s research will move the industry forward toward justifying these benefits,” says structural engineer Evan Reis, executive director of the U.S. Resiliency Council. The MIT CSHub is funded by the RMC Research & Education Foundation and Portland Cement Association. Sources: MIT news release and July 12 edition of ACI Concrete SmartBrief. Read more here. Buildings

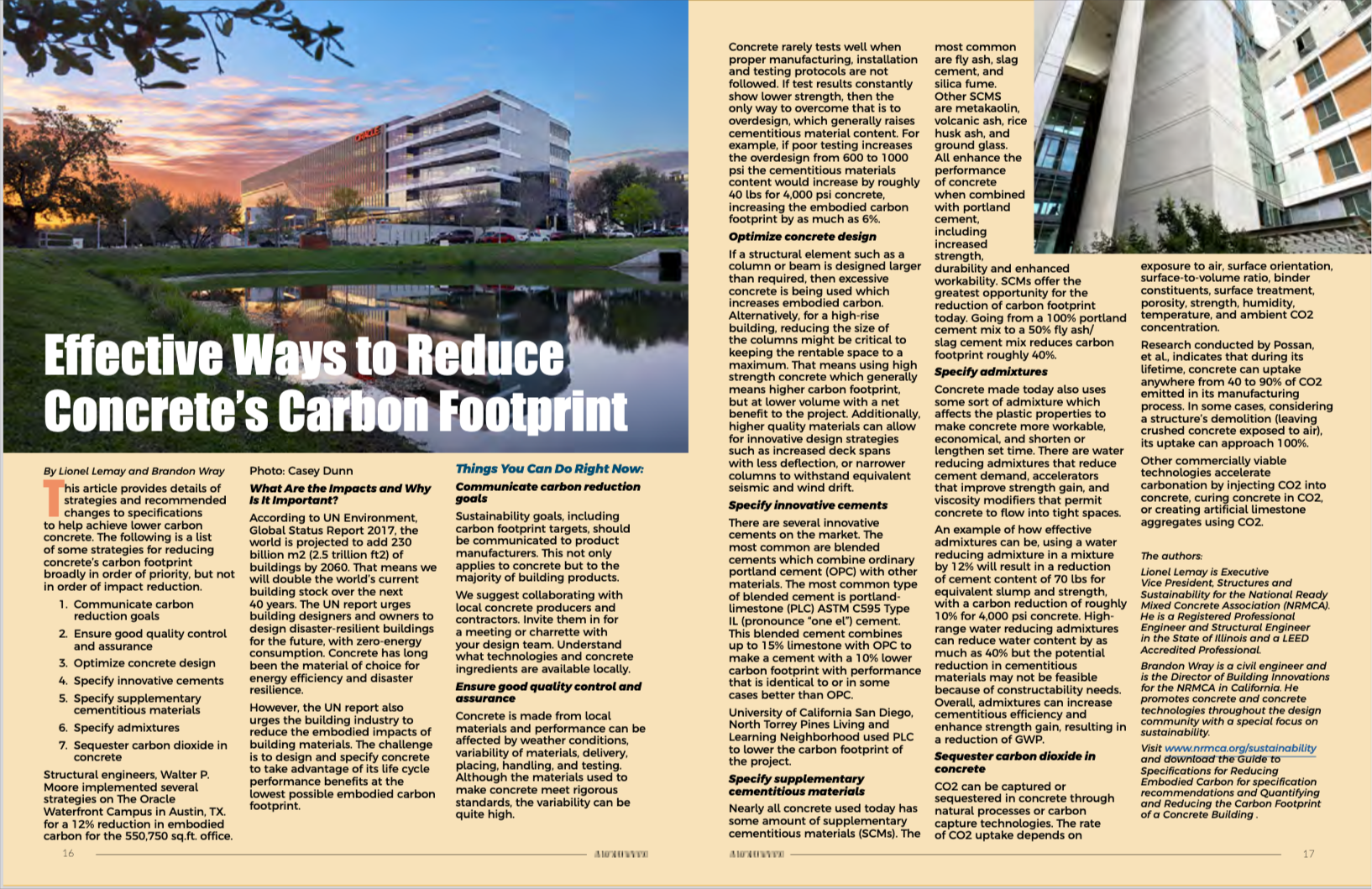

The Connecticut Concrete Promotion Council (CCPC) and Build With Strength's efforts in Connecticut were recently recognized by AIA Connecticut as its 2022 Allied Member of the Year. In a letter to council Executive Director Dominic Di Cenzo, AIA Connecticut Executive Director Gina Calabro wrote, “the Allied Member of Year recognizes an allied member who is not an architect but who, by their interest, participation and concern, has promoted and contributed significantly to the profession of architecture. Your work and services exemplify these criteria and your involvement with members is highly noted. We thank you for your invaluable contribution to the design profession and the Connecticut architectural community. You and other worthy award recipients will be honored at the Awards Gala on November 15.” The CCPC and Build With Strength Connecticut have hosted several Coffee & Concrete Tours to concrete and ICF construction projects, most recently with a tour to a Pound Ridge, NY, project which saw some 35 AIA Connecticut-based attendees. NRMCA personnel have presented numerous webinars and presentations on ICFs, concrete innovations and the 10 ways to reduce concrete’s carbon footprint. The CCPC has regularly contributed technical articles and advertisements in the monthly digital Architype magazine (example, seen here); has presented during Sustainable Architecture month (April); has been a presenter and exhibitor at the annual CACX Conference and Expo; and CCPC Director Di Cenzo has moderated panel discussions on ICF construction and also sits on the AIA Connecituct’s school construction committee. For more information, contact Dominic Di Cenzo at ctconcretepromotion@gmail.com.

Pavement

Earlier this year, the Federal Highway Administration (FHWA) announced its Climate Challenge with the purpose of “exploring challenges and needs related to the quantification of greenhouse gas (GHG) emissions associated with the design, construction, and maintenance of pavements using Life-Cycle Assessment (LCA) and Environmental Product Declarations (EPDs).” Currently, the FHWA is accepting proposals from state departments of transportation (DOTs) to investigate the regular use of LCA and EPDs to inform pavement material and design selection for enhancing sustainable pavement practices and quantify the emissions and impacts of those practices. DOTs may receive up to $500,000 from the FHWA to conduct these studies; the deadline for proposal submission is Monday, August 1. Work sponsored by the RMC Research & Education Foundation (RMCREF) and conducted at the Massachusetts Institute of Technology’s Concrete Sustainability Hub (MIT CSHub) over the last decade is perfectly positioned to inform the analyses that state DOTs will conduct to meet the goals of FHWA’s Climate Challenge. “These are excellent opportunities for states to discover how sustainability concepts may be used to make informed decisions about paving materials throughout the full pavement lifecycle,” said NRMCA Executive Vice President, Local Paving, Brian Killingsworth. “We encourage all state DOTs to participate in the climate challenge and rest assured that personnel from the NRMCA, RMCREF, MIT CSHub and other concrete industry organizations are working with DOTs to secure funding for the climate challenge to properly assess concrete materials and meet the August 1 deadline.” Click here for more information on the climate challenge. Last week, NRMCA Senior Director, Building Innovations, Patrick Matsche and his colleague Don Clem, Vice President, Local Paving, presented Top Ten Ways to Achieve Low Carbon Concrete to Seattle-based LPD Engineering. LPD Engineering is the design engineer for a new electric bus facility which will include a large concrete parking lot. The project architect and contractor also attended. NRMCA is assisting LDP Engineering in designing the concrete pavement, as well as exploring ways to minimize the carbon footprint of the concrete mix, to meet King County environmental goals. Antara Choudhary, market development manager, Northwest Cement Council, also attended and provided background on her work on type 1L cement while working on her PHD at Oregon State University. For more information, contact Patrick Matsche at pmatsche@nrmca.org or Don Clem, dclem@nrmca.org. Calendar

Please note that e-mail and direct registration links to each event listed below can be accessed from NRMCA's website. August 1 - 2, Centennial, CO August 17, Online Course August 25, Las Cruces, NM September 14, Little Rock, AR September 29 - October 3, Aurora, CO October 18 - 20, Charlotte, NC October 18 - 21, Dallas November 8 - 10, Louisville, KY November 15 - 17, Phoenix November 29 - December 1, Orlando, FL December 6 - 8, Dallas December 13 - 16, Kansas City, MO |

||||||||||||