UMV "Cracking Code" for Future Fossil Free Barrier Coatings

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

UMV Coating Systems, Säffle, Sweden, reports that it is about to crack the code of how to coat papers and board with fossil free barriers, creating the opportunity to produce food packaging that is 100% made from biological materials. Coating board for food packaging with fossil free barriers has long been a hard nut to crack, UMV notes. No one has yet succeeded in doing this on an industrial scale without creating pores in the barrier, making packaging less dense and thus unusable, it adds.

UMV Coating Systems, Säffle, Sweden, reports that it is about to crack the code of how to coat papers and board with fossil free barriers, creating the opportunity to produce food packaging that is 100% made from biological materials. Coating board for food packaging with fossil free barriers has long been a hard nut to crack, UMV notes. No one has yet succeeded in doing this on an industrial scale without creating pores in the barrier, making packaging less dense and thus unusable, it adds. But after a week-long pilot run, it appears that UMV Coating Systems is on the way to solving this global problem. "It looks promising, but we don’t want to draw any conclusions before all of the analyses are made," said Per Emilsson, coating expert at UMV Coating Systems.

Last spring, UMV Coating Systems was granted funding from Vinnova to conduct pilot tests with its newly developed coater, INVO Coater. Initial analytical work undertaken at the University of Karlstad n Sweden had yielded promising results. The university then wanted to go ahead with a major investigation to study the concept coating fossil-free barriers in full scale.

During week 36, UMV Coating Systems has conducted 35 pilot runs on its own machinery in Säffle, and two researchers from the University of Karlstad have analyzed the results.

"We tested how good the barrier is, and it looks very promising. We will now carry out a battery of tests to determine the different barrier properties. We will also check for fat resistance, oxygen permeability, and much more, in accordance with established standard methods for testing barriers in food packaging. There is still a lot of analysis to do, but so far we have only seen positive results," said Pia Eriksson, a development engineer at the University of Karlstad.

UMV reports that cooperation with the University of Karlstad is working perfectly, and that final results of their analysis are expected to be completed in December. If the barrier is adequate, it could mean that it will be possible to produce completely fossil free and biodegradable food packaging that can handle future environmental legislation.

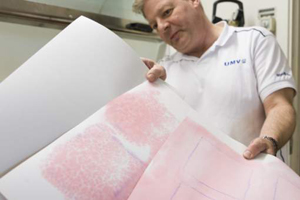

In the photo, Per Emilsson at UMV Coating Systems compares barrier tests. On the far left, an example can be seen completely without red penetration, indicating a tight barrier.