Paper Scaffolding Provides Eco-Friendly Construction, Packaging

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

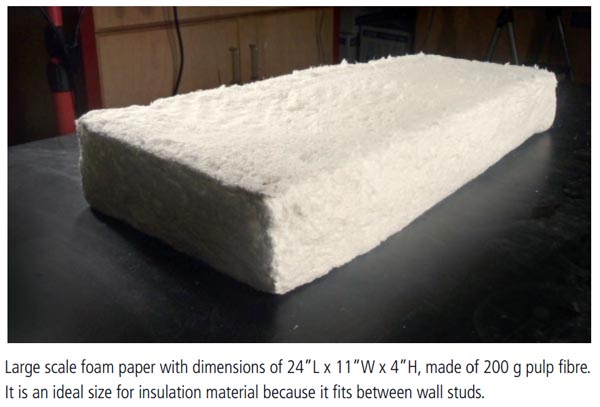

The University of British Columbia (Canada) recently put together a team of researchers who successfully created a solvent-free and low-cost process to produce a low-density cellular foam "scaffold" by using green fibers. The porosity and mechanical properties of the foam can be easily adjusted, depending on requirements. This lightweight foam is 100% natural, biodegradable, and carbon-neutral, and it is suitable for a wide range of applications from construction to use in the biomedical industry.

The impact includes:

- In addition to not using solvent, the production process uses significantly less water than traditional foam-forming methods

- Moves many foam industries towards a greener, renewable alternative product

- Reduces the cost of transport and recycling process for foam producers

- Moves construction industry and building towards LEED certification

- Highly antimicrobial, making it great for any food packaging.

Other potential applications include:

- Hospital air filtration systems or clean rooms

- Sound-absorent walls or acoustics for recording rooms

- Thermally insulated (hot or cold) packaging for long-distance transport

- Water filtration

- Enviornmental bioremediation.

For more information email James Olson, the principal investigator for this new product at the University of British Columbia.