Biomass to Biobutanol: Cost Effective Alternative to Petroleum-Based Production

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

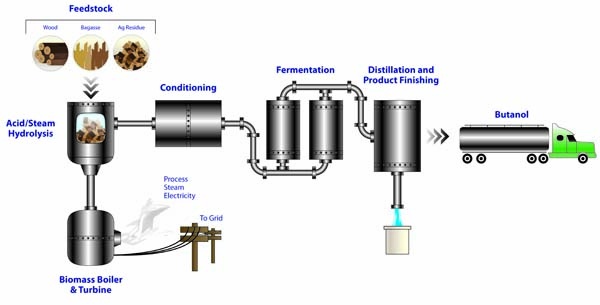

According to a report this past week by BioFuels Digest, Key Biscayne, Fla., USA, Cobalt Technologies is commercializing cellulosic biobutanol, a versatile platform molecule for renewable chemicals and fuels. The company’s technology efficiently converts diverse non-food feedstocks—initially, lignocellulosic extracts from woody biomass and sugar cane bagasse—into biobutanol.

Cobalt will offer complete systems for sugar mill, pulp and paper, and biomass power facility retrofits with a cost-effective biorefinery module, taking advantage of benefits of co-location (feedstock supply, logistics, permits) while enhancing overall facility returns. Feedstock for the biorefinery will be low-value hemicellulose and cellulose extracted from bagasse or woody biomass, and other available low-cost feedstocks, according to the BioFuels Digest article.

As explained in the article, biobutanol can be used as is in paints, coatings and other chemical products, a 1.2 billion gal., $7 billion global market. It can also be converted via known chemistry into a wide range of high value products, including 1-butene, isobutene, and butyraledehyde derivatives, replacing petrochemicals. This allows access to a 67 billion gal., $300 billion market. The group can also produce full performance jet fuel and diesel. Biobutanol can also be blended with gasoline, diesel, and ethanol to reduce emissions, the article adds.

Engineered to achieve low costs through high productivity, energy efficiency, and the use of low-cost feedstock, Cobalt is making biobutanol and its derivatives a cost effective substitute to petroleum-based materials.