Papeterie Sical Starts up Toscotec Rebuilt Containerboard Machine in France

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

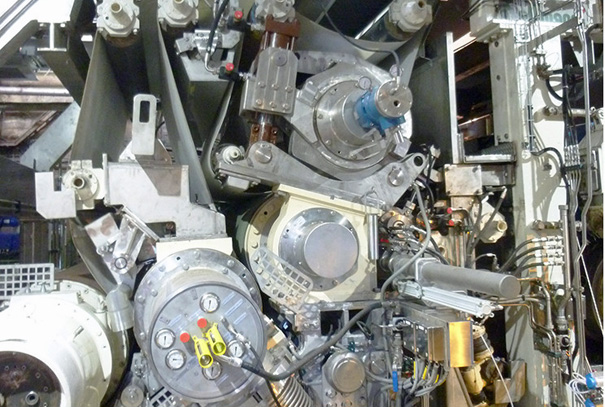

Papeterie Sical, located in the Nord-Pas-de-Calais region of France, and Toscotec, Italy, this week announced the successful startup of PM 1 after an extensive press section and related parts modification. The machine came in operation according to the planned shutdown time and, after the optimization phase, is now producing targeted containerboard quality.

The project, designed to improve press dryness performance, liners top side printability, and machine runnability, includes a new TT Combi-Press with a tailored TT Pick-up press roll, new press rolls with related cleaning doctors, a major press frame rebuild integrated in the wire section structure, and a complete tail threading from press to dryer section, including the area of the existing shoe press in the last position. A broke pulper modification and a new TT steel Dryer in the initial part of the dryer section were part of the rebuild that includes erection, erection supervision, startup assistance, and training.

With a web width of 2,570 mm and a design speed of 500 m/min, the renewed PM 1 produces containerboard grades as brown test liners, brown liners, and medium in the range of 100 to 220 gsm, with a capacity of 45,000 metric tpy.

Papeterie Sical is part of the European-based Rossmann Group, an independent packaging manufacturer in Europe and Africa, with a box plant production capacity of 500,000 metric tpy. With 10 sheet plants in Western Europe and one in Burkina Faso, with a yearly capacity of 300,000 metric tpy of papers made from recycled fibers, Grossman Group offers various kind of printed packaging.

Beginning in 1948, Toscotec offers complete production lines, plant retrofits, and individual machineries for the tissue and paper and board industries. With offices in China and North America, as well as headquarters in Lucca, Italy, the Group serves leading paper producers worldwide.