Sonoco Alcore Revamps Dryer Section with Advanced TT SteelDryers at Ciriè Mill

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

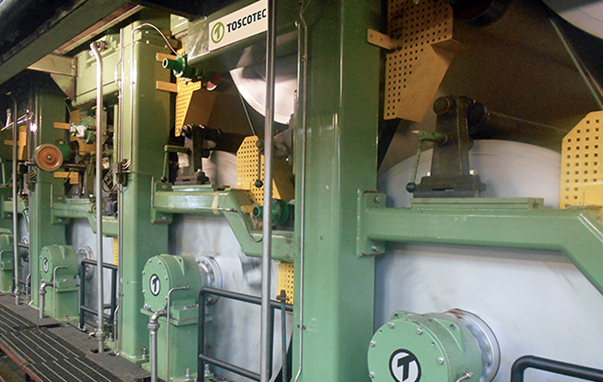

A Toscotec (Lucca, Italy) dryer section rebuild has been successfully started up at Sonoco Alcore’s paper mill in Ciriè–Torino, Italy. PM 1 in Ciriè, with a reel trim of 2,500 mm and a design speed of 350 m/min., is specialized for the production of high quality core board grades.

The goal of investment was principally to increase the production, optimizing both efficiency and dryer section runnability by rebuilding of several dryer groups. A total of 15 new TT SteelDryers in place of cast iron dryers has been provided, together with the modernization of mechanical drive and tail threading implementation.

The specific design of TT SteelDryer with flat heads welded to the shell allows the machine to produce a wider and uniformly dried-out sheet. Toscotec was the first to introduce the revolutionary concept of steel dryers in the paper industry. Today it has more than 1,200 installed units worldwide.

A new mist removal device has been supplied in the forming section, to increase the wet section cleaning and efficiency.

The expected shutdown time was met and productivity targets were immediately achieved after the startup.

Sonoco Alcore is a wholly owned subsidiary of Sonoco, Hartsville, S.C., USA, a global provider of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. Sonoco Alcore is a leader in high-quality, innovative, value-creating tube and core solutions, operating 29 tube and core plants and four paperboard mills in Europe.

Since 1948, Toscotec has offered complete production lines, plant retrofits, and individual machineries for the tissue and paper and board industries.