Sappi Maastricht Orders Valmet Machine Rebuild to Board Production

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Valmet, Finland, will rebuild a paper machine for Sappi Maastricht in the Netherlands. With the rebuilt PM 6, Sappi will be able to improve the existing graphical board products and move into producing high quality solid bleached board (SBB) and folding box board (FBB) grades. Today PM 6 is producing coated woodfree (CWF) paper grades. Startup of the rebuilt machine is scheduled for early 2018. The value of the order was not disclosed.

"All of the technical ideas were tested in pilot conditions at our Paper Technology Centers. With the results from the pilot trials and in close partnership, Sappi and Valmet were able to develop a new concept for Sappi Maastricht—a concept with some unique solutions," said Sales Manager Kari Sorsa from Valmet.

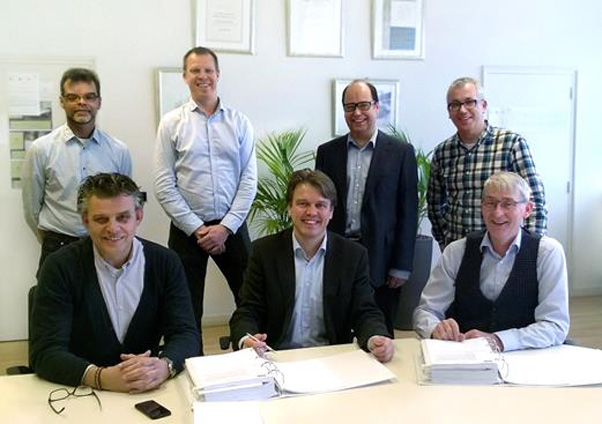

Signing the contract are (back row from the left): Marco Duschak (Valmet), Iiro Luostarinen (Sappi), Kari Sorsa (Valmet), Peter Pijpers (Sappi), (front row from the left) Rob de Koning (Sappi), Marko Oinonen (Valmet), and Peter Loubele (Sappi).

Valmet's delivery for PM 6 will include a new type of OptiFlo headbox and OptiCalender Metal Belt calender. With the headbox, an optimal sheet structure with improved paper properties can be achieved.

The calender ordered by Sappi Maastricht will be the ninth OptiCalender Metal Belt to be supplied by Valmet. With this unique technology, bulk of the produced board can be increased significantly. The surface smoothness, topography, and printability of the calendered end products are excellent.

PM 6 will be producing graphical board, SBB, and FBB in the basis weight range of 220-450 gsm. The mill has a total capacity of 280,000 metric tpy.

Headquartered in Brussels, Belgium, Sappi Europe is a producer and supplier of coated fine paper, packaging, and specialty papers. In Europe the company has seven mills, 14 sales offices, and 5,100 employees.