Lucart Sustainability Report Illustrates Results Achieved, Prospects for Development

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

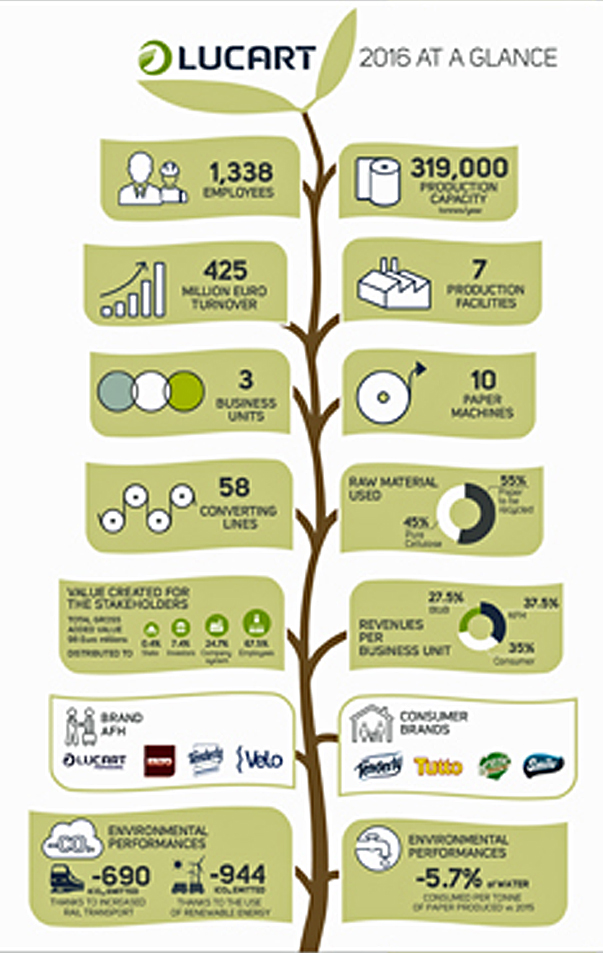

Sustainability and innovation are the two mainstays of Lucart's (Italy) activities, which have allowed it to achieve outstanding results, as illustrated by the company’s 2016 Sustainability Report. Lucart is the first company in Italy to have launched a circular economy project in the tissue paper sector.

"I believe that we can be considered as a company that promotes a sustainable way of producing paper," Massimo Pasquini, managing director of Lucart, commented, "which is based on a systemic approach aimed at eliminating waste and reusing raw materials. To do this, we constantly strive to apply production and business models that are inspired by the circular economy and that are in line with EU environmental requirements. We are proud of the results we have achieved this year, since they are a successful example of our ongoing commitment to pursuing innovative and high-quality production. We will continue to carry out all of our activities by placing people and the environment at the center of our business strategy, leading the way towards a more sustainable future."

Lucart has made positive progress towards the progressive elimination of waste and the reuse of raw materials, favoring the use of recovered materials (55% in 2016) over pure virgin cellulose (45%) for the production of its paper. The flagship of this sustainability strategy is the Natural project, a true example of the applicability of circular economy principles to the tissue sector.

This virtuous and award-winning project represents the evolution of paper, combining environmental sustainability and technological innovation. In partnership with Tetra Pak®, Lucart has developed an innovative technology that separates the cellulose fibers in beverage cartons from polyethylene and aluminium parts, without the use of substances that are harmful to humans or the environment. In this way, two new high-quality raw materials are produced. Fiberpack®, the paper used for the hygiene products in Lucart's Natural lines, is obtained from cellulose fibers. The company has also obtained a material called AL.PE.® from polyethylene and aluminium. This raw material is used to produce innovative systems for the dispensing of tissue products but also for pallets, mooring poles in Venice, and floating platforms for wheelchair access and other commonly used items, which are all recycled and recyclable when they reach the end of their life cycle.

In just four years, from 2013 to 2016, the Natural project has produced great results:

- More than 2.8 billion 1-liter beverage cartons have been recycled, which, if lined up one after the other, would cover a distance equal to the circumvention of the Earth 16 times over

- More than 1.2 million trees have been saved thanks to this initiative, equal to a surface area of more than 4,200 football fields

- More than 73,000 metric tons of CO2 have been avoided, equal to the emissions produced by more than 578,000 Rome-Milan trips by car.

The Natural project received an award on the occasion of the 14th edition of the "Sodalitas Social Award 2016," namely, the "Best in Class" award, the most prestigious prize for corporate sustainability in Italy, and it also received the "Premio Non Sprecare" (Don’t Waste Award) in the "Companies" category in the same year, thanks to its innovative and sustainable approach to circular economy and consumption. Lucart recently ranked second at the 6th edition of the European Paper Recycling Awards held in Brussels, for the Research & Development category, and received the EU Ecolabel Award 2017 for researching and developing new production and environmental solutions.

Lucart has focused on using less raw materials and, in particular, on water resources by favoring water recycling, constantly monitoring the quality of wastewater as well as consumption in the various phases of the production process, and optimizing consumption patterns. This resulted in a reduction in the specific water consumption for paper production with savings of -5.7% of water consumed per tonne of paper produced compared with 2015 and an overall reduction of 14% compared with 2014.

With regard to logistics, Lucart has significantly reduced its impact on the environment in terms of emissions: 690 metric tons less CO2, thanks to increased rail transport, as part of the project "Sustainable Mobility: raw material transport with a shift from road to rail," presented in 2015 and continued in 2016. The project, which mainly concerns the plant in Diecimo, in the province of Lucca, aims to use the existing railway network to significantly reduce the transport of raw materials and finished products by road.

In terms of energy resources, the company is constantly committed to making its production processes become increasingly efficient. Lucart was also one of the first paper manufacturing groups in Europe to focus on systems to self-generate electricity through cogeneration plants powered by methane gas.

As for its emissions into the atmosphere, Lucart has implemented a plan aimed at streamlining energy consumption by using energy from renewable sources, allowing for lower emissions per ton of paper produced.

Lucart, a leading European company in the production of MG paper, tissue products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs, etc.), and airlaid products, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over three business units (business-to-business, away from home, and consumer). Its production capacity exceeds 300,000 metric tpy of paper on 10 continuous machines and 58 converting lines. Its consolidated turnover amounts to more than EUR 400 million, with more than 1,300 employees in seven production plants (five in Italy, one in France, and one in Hungary).