Toscotec to Supply Dryer Section Rebuild to Papertech

![]() Print this Article | Send to Colleague

Print this Article | Send to Colleague

Toscotec, Italy, was selected to rebuild the dryer section of Papertech PM 1 at Tudela mill, Spain. The customer selected Toscotec as the right partner to provide the best technology available in the drying process and to accomplish the company targets.

The aim of the project is to improve actual gross production by overcoming several constraints by applying Toscotec’s Steel Dryer technology and its features. The base project goals were increasing production by maintaining the same length of dryer section and drying a wider paper sheet with the same dryer face length.

The scope of supply will be on a turnkey basis, confirming once more the consolidated skill of Toscotec to manage complex projects and coordinate all of the involved parties.

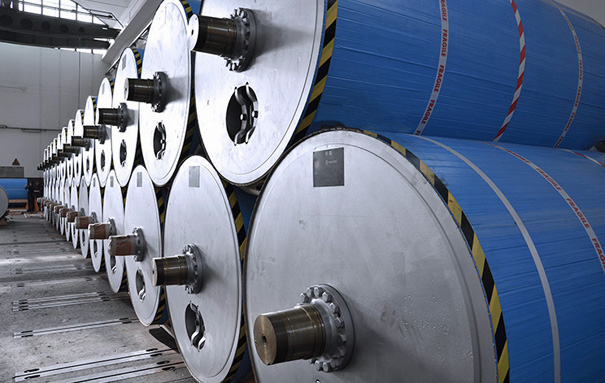

A key factor of the dryer section modification is to replace completely the last four sections with TT SteelDryer technology, thus resulting in 20 new TT SteelDryers with increased diameter and drying face width. The scope of supply also includes TT AirTail, an advanced rope-less tail threading system, specifically designed for low speed and high basis weight.

Toscotec’s service specialists will provide erection, supervision, commissioning, and startup assistance.

Delivery is forecast within the end of 2018, with startup at the beginning of 2019.

Papertech is a core board specialist having more than 60 years of experience producing paper from 200 up to 1000 J/m2 PlyBond. Their wide product range allows their customers to manufacture any industrial tube they need, regardless of the needs of the final customer. Papertech produce annually more than 300,000 tons of special industrial papers in three countries Spain, Indonesia, and China.