Sofidel to Install Two More Energy Recovery Systems at Italy, Poland Tissue Mills

To increase energy efficiency of its tissue production lines, Sofidel SPA in Italy has ordered two Advantage ReTurne energy recovery systems from Valmet. The system does not only recover energy from the headbox jet power, but also returns it back to the process as electrical energy. The value of the order was not disclosed.

This will be Sofidel's second and third installation of the innovative energy saving solution and will be installed on the Delicarta mill's TM 2 in Italy and Delitissue mill in Poland. The first Advantage ReTurne installation started up at Sofidel's Delicarta mill in Valdottavo, Italy in 2014 and proved to fully meet the expectations right from the start, according to Valmet.

For Sofidel, it is important to find new innovative solutions to reduce the environmental impact of its production. The company has joined Climate Savers, the international program promoted by WWF (World Wildlife Fund), to voluntarily adopt plans to reduce emissions of greenhouse gases using innovative strategies and technologies.

"The first installation of Valmet's Advantage ReTurne energy saving system has been a positive experience for us. Its energy saving capabilities turned out to be better than we hoped for. Therefore we have decided to improve the energy efficiency in two more of our tissue machines," said Simone Capuano, vice chief technical officer, Sofidel.

"Energy saving is high on our customers' agendas, and we are working hard to develop energy efficiency in our new and existing tissue making solutions. Our high expectations on the first Advantage ReTurne system were substantially exceeded. We are thus convinced that the two new installations will be as successful as the first one, and will help Sofidel reach its environmental targets," noted Johan Björn, sales director EMEA, Valmet.

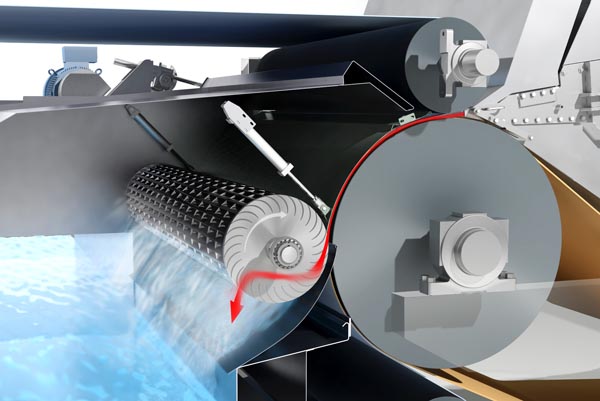

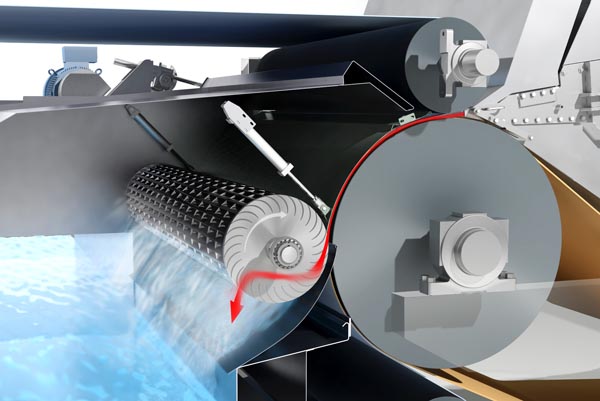

The Advantage ReTurne energy recovery system is installed in the forming section. It is unique in that it recovers 50% of the energy from the headbox drainage water and via a generator converts it into electrical power, which is supplied to the sectional drives. The Advantage ReTurne does not affect the formation of the paper or the tissue making process; it is easy to handle and has low maintenance needs. This new innovation is very efficient in both new and existing tissue machines.

The Sofidel Group produces paper for hygienic and domestic use. Established in 1966, the group has subsidiaries in 13 countries—Italy, Spain, Sweden, the U.K., Belgium, France, Croatia, Germany, Poland, Romania, Greece, Turkey, and the USA—with more than 5,200 employees. With a consolidated turnover of EUR 1,771 million (2014), Sofidel is the second ranking group in Europe in terms of production capacity in the tissue sector (1,050,000 metric tons per year in 2014).

TAPPI

http://www.tappi.org/