Cascade Pacific Plans New Waste Plume Fix

According to a recent report by the Gazette Times, Cascade Pacific Pulp, Halsey, Ore., USA, is taking another run at eliminating an unsightly waste plume that periodically stains the Willamette River downstream from its Halsey pulp mill.

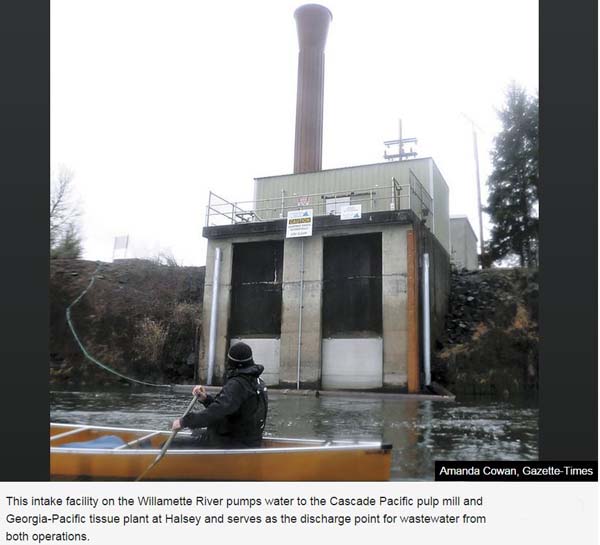

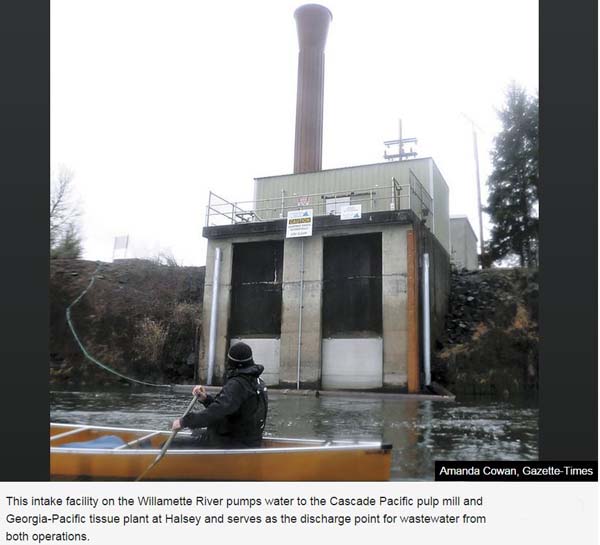

Over the past two years, the company has spent about $2 million to address the problem, which occurs when low river flows fail to adequately dilute the plume of treated effluent coming out of a combined water intake/wastewater discharge facility 15 miles upstream of Corvallis. The facility is owned by Cascade Pacific and also serves an adjoining tissue plant operated by Georgia-Pacific, Atlanta, Ga., USA.

Under discharge permits issued by the Oregon Department of Environmental Quality, the treated wastewater from the two operations is supposed to be dispersed by the river’s current by the time it leaves the mixing zone downstream from the outfall pipe.

But in recent years a gravel bar has formed just upstream from the site, cutting water flow past the outfall. When river levels are low, this can result in a long, dark-colored plume of effluent extending well beyond the mixing zone’s boundaries.

Cascade Pacific tried engineering an artificial channel through the gravel bar in 2013, but winter floods filled it back up again. Additional dredging at the site last year turned out to be a temporary solution.

Now, on the advice of a consultant, the company wants to move its outfall pipe 1,300 ft. downstream, to a deeper spot in the channel below the gravel bar, and replace the 1960s-era diffuser with a new and improved model. Like the original diffuser, the replacement will consist of a 100-ft. pipe with 20 smaller exit pipes to discharge the effluent, but the exit pipes will have updated "duckbill-style" ports on the ends arranged in a fanned orientation to maximize mixing with the river water.

Both Cascade Pacific and Georgia-Pacific are seeking modifications to their DEQ wastewater permits to allow the changes. Pat Rank, GM of the Cascade Pacific plant, hopes the new approach will provide a permanent fix to the waste plume problem. "The bank is very stable and the river’s deep there," he said. "The new diffuser with the duckbills distributes the effluent much more evenly, so it will diffuse better."

It will have to perform better than the old system to meet new requirements proposed by DEQ, which wants to shorten the mixing zone allowed by the permit from 300 ft. downstream of the pipe to just 40 ft.

To boost the relocated diffuser’s prospects for success, the company is taking 1,300 ft. of river frontage it owns at the site out of agricultural production and planting that stretch of bank with native trees, plants, and grasses to further stabilize the bank.

Rank said Cascade Pacific hopes to start on the project this summer, but work can’t begin until all of the proper permits are in hand. In addition to DEQ, the company also needs approval from the U.S. Army Corps of Engineers, the National Marine Fisheries Service, and the Oregon Department of State Lands.

Rank said he’s not yet sure how much the latest improvements will cost, but "it’s certainly not for the faint of heart."

The twin pulp and tissue mills at Halsey are among the largest industrial employers in the mid-valley. Cascade Pacific has about 185 workers at the site, and Georgia-Pacific employs 300 to 400 more.

TAPPI

http://www.tappi.org/