Metsä Group Orders Valmet Sulfuric Acid Plant for Äänekoski Bioproduct Mill

Valmet (Espoo, Finland) announced late this past week (May 20) that the company will supply a sulfuric acid plant to the Metsä Group (Helsinki, Finland) bioproduct mill in Äänekoski, Finland, for in-house sulfuric acid production. By means of a new sulfuric acid plant of its own, the bioproduct mill can utilize the chemicals in the odorous gases of the pulp manufacturing process. This will help to reduce waste water load considerably. Startup of the plant is scheduled for the third quarter of 2017.

Valmet`s delivery is part of Metsä Group`s sulfuric acid plant investment that is valued at roughly EUR 20 million. The exact value of the order was not disclosed.

"The sulfuric acid plant producing process chemicals from sulfur compounds from odorous gases is a remarkable step towards closed chemical circulation and further improves the environmental performance of the bioproduct mill," said Timo Merikallio, project director of the bioproduct mill at Metsä Group.

"More efficient utilization of the raw materials and putting circular economy into practice within the industry increases the need for new innovations. The sulfuric acid plant technology that will be delivered to Äänekoski is developed by Valmet. We have developed also multiple new biotechnology processes for pulp and energy industries including lignin and bio-oil production," added Valmet Environmental Systems Director Risto Hämäläinen.

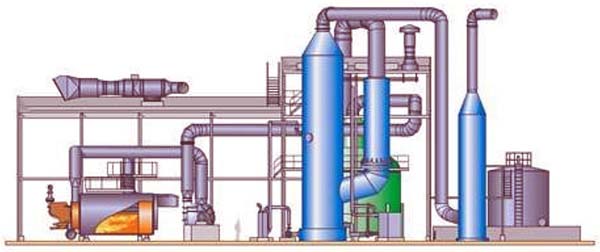

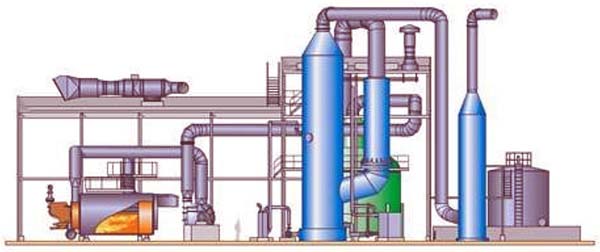

The order includes a sulfuric acid plant developed by Valmet. The plant's components (pictured above) consist of a concentrated non-condensable gas (CNCG) incinerator and a sulfuric acid converting plant. The production capacity of the plant will be approximately 35 metric tons of sulfuric acid per day. This will be the world`s first larger scale sulfuric acid plant that will be in operation at a pulp mill.

The new plant will enable the bioproduct mill to become nearly self-sufficient in sulfuric acid, as the odorous gases produced in the pulping process can be converted into sulfuric acid. This will bring significant environmental advantages. The amount of sulfate lead to the mill`s effluent treatment plant will be reduced and the sulfate load in the nearby waterways will be smaller compared with the current mill in Äänekoski. The CNCG incineration plant can be used as a back-up boiler for producing process steam by incinerating CNCG, tall oil pitch or liquid methanol.

TAPPI

http://www.tappi.org/