Coldwater Reports Record Orders for Edge Control Systems

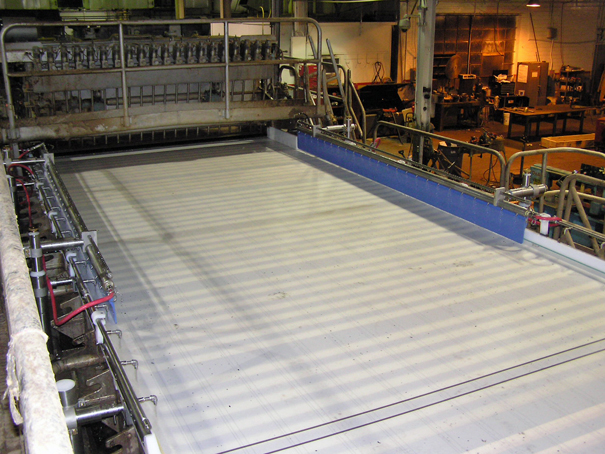

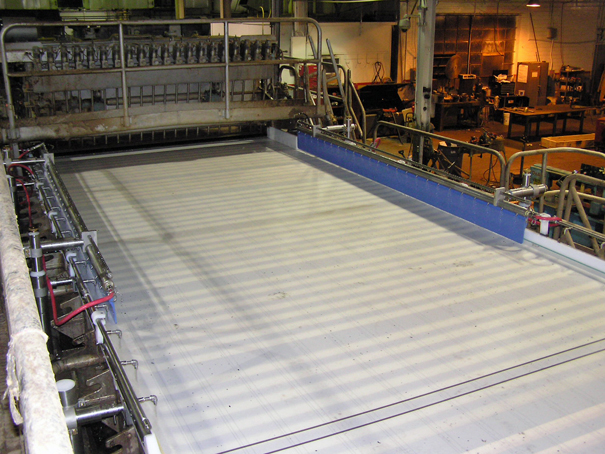

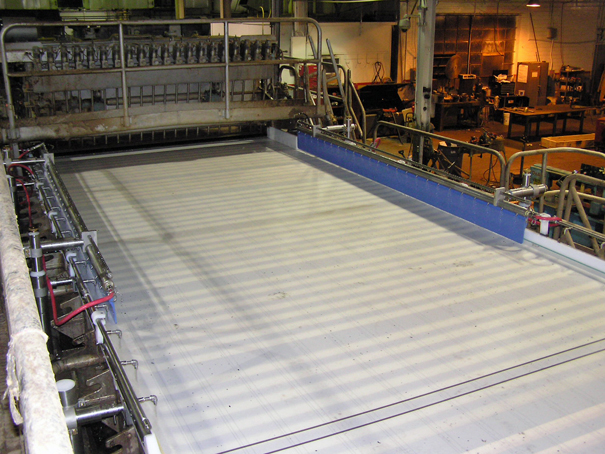

Doug Wall, VP of sales and marketing, this week announced that Coldwater, Atlanta, Ga., USA, has had a record number of global orders in 2016 for its FabCurl™ and Deckle Board Edge Control Systems. Orders this year have been received on pulp, linerboard, corrugated medium, and coated containerboard machines ranging from 7 meters to 9 meters in width in North America, Europe, and Asia. With the growing demand for improved sheet profiles and overall quality, as well as improved machine performance and efficiency, Coldwater’s FabCurl (photo below) and Deckle Board Systems are delivering significant improvements in all of these areas.

Part of this success is due to the fact that the FabCurl System’s unique baffle board design dips into the stock, giving papermakers the ability to eliminate or manage the location of edge waves on the fourdrinier table. Plus, each FabCurl System includes well positioned showering to keep it clean, quick release pins for fast and easy wire changes, and robust stands for the rigidity required in this demanding application. Improved performance examples include a bleached board mill that saw a 70% reduction in 2 sigma basis weight profile, and a linerboard mill that saw a 2% increase in production through increased saleable trim.

Coldwater is a global innovator in paper machine consumables and engineered products that optimize paper machine performance and reliability. Other product lines include dryer and felt passivation, suction roll sealing components, doctor blades, Lantier doctoring equipment, Wilbanks ceramics, premium UHMW drainage elements, headbox parts and services, and combinations of the above in complete consumables optimization management programs.

In addition to its headquarters in Atlanta, Coldwater has manufacturing facilities in Appleton, Wis.; Karlstad, Sweden; and Kunshan, China; and sales offices in Spain and Thailand.

TAPPI

http://www.tappi.org/