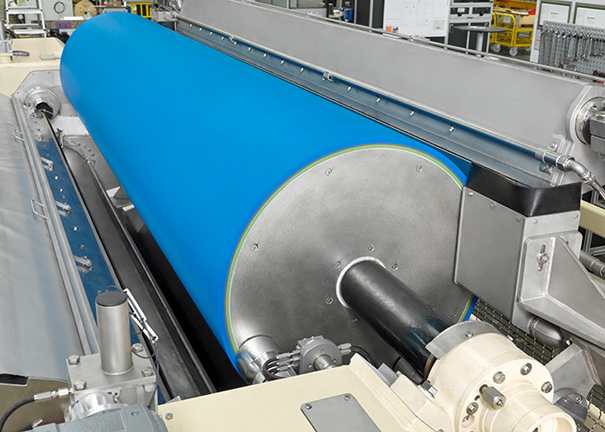

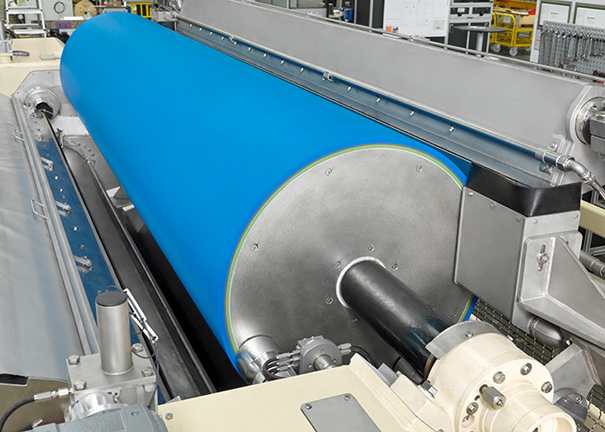

Voith OceanCoat Roll Cover Provides Cost Savings, Improved Efficiency

With OceanCoat, Voith is adding a highly durable option to its portfolio of coater roll covers. The especially stable material needs regrinding less often than standard roll covers, which reduces shutdown and maintenance costs.

Voith's new OceanCoat stands out from standard roll covers through its color alone. The blue shade allows the operator to quickly identify any overheating, which commonly occurs at the edges. This enables appropriate steps to be taken promptly. Additionally, the blue cover material is easier to clean, which notably reduces the downtime after a break. Thanks to the high mechanical stability of the cover material, OceanCoat is also able to withstand loads caused by breaks or paper wraps better than standard covers.

Other important benefits of the cover include the low degree of wear and reduced symptoms of aging. The desired roughness of the cover stays more constant over the operating life than a standard cover.

OceanCoat is designed to run dependably in a wide range of coater backing roll positions. More than a dozen OceanCoat covers are already operating successfully. Customers currently using the cover are placing additional orders, proving that they are very pleased with its performance. Users are highlighting the abrasion resistance, consistent roughness that results in stable operating conditions, and the fact that the cover is easy to clean after a break. Mills have realized significant cost savings through the use of OceanCoat.

TAPPI

http://www.tappi.org/