Lucart to Install New Toscotec Tissue Line at Porcari Mill

Focusing even more on the tissue market is the goal of Lucart Group, an Italy-based producer of MG paper, tissue, and airlaid products. Lucart is replacing one of the two MG paper PMs installed in 1976 at its Porcari plant in the province of Lucca, Italy, with a new line manufactured by Toscotec, Italy, a multinational company leader in the supply of papermaking plants, machinery, and technology.

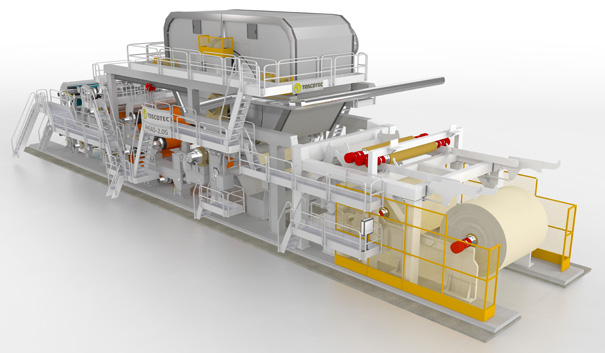

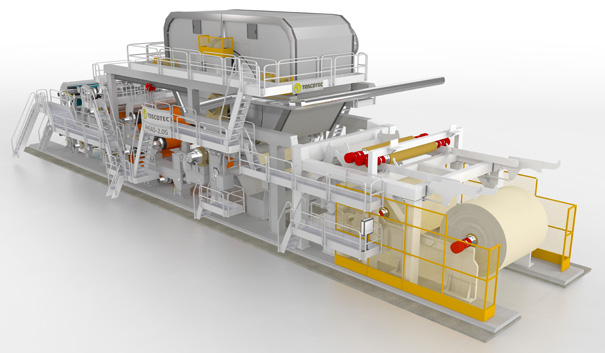

The new AHEAD-2.0S tissue machine is equipped with the most innovative technological solutions.

The forming section is designed for the future installation of a new system aimed to increase the dry content and thickness of the finished product. The dry section includes the TT DOES solution with the shoe press TT NextPress, a TT SYD-16FT second-generation steel yankee dryer and high-efficiency hoods that guarantee high quality paper with the lowest possible energy consumption.

The pope reel section, with the new TT REEL-H+, is designed to maintain the characteristics of the sheet, thanks to the use of the core assist drive on the primary and secondary arms. With this new system by Toscotec, reel change takes place at the maximum operating speed and at full format.

To ensure that the work environment of this new machine complies with the latest regulations, the PM will be equipped with mist and dust suction systems.

The scope of supply includes the new automatic rewinder equipped with three unwinding stations (maximum operating speed is 2,000 m/min.), with technology aimed at preserving paper thickness during reel winding.

Installation will be finalized in the second semester of 2018. Toscotec’s YES – Your Expert Service – service division will provide supervision for erection, startup, and training of the paper mill’s personnel.

The line will produce high quality tissue paper starting both from pure cellulose and recycled paper. The operating speed is 2,000 m/min. and the total production is approximately 35,000 metric tpy.

PM 3 will continue the production of all types of MG paper for flexible packaging. PM 3 will undergo technical improvement interventions to ensure the highest production quality.

"This important investment," explained Massimo Pasquini, Lucart CEO, "allows us to strengthen our presence in the tissue market. Indeed, we believe that the growth of the company in the market of paper for hygienic-sanitary use in Europe is strategic, and the new PM will foster the development of all of the business units of our group. We are pleased to look at the world without forgetting our origins; for this reason, installing cutting-edge technology at our historical Porcari mill, in the province of Lucca, should be seen as a message of trust towards Italy as a whole. Working with a partner like Toscotec was a very positive experience for us and we hope that this collaboration will continue in the future."

Alessandro Mennucci, Toscotec CEO, noted that "once again, our innovative technology allows us to respond in a timely manner to the needs of our customers. We are pleased to be able to support Lucart in this new growth project in the tissue market. For us, standing by their side represents an important reference and a further spur for the development of new solutions for an increasingly demanding market."

Lucart was founded in 1953 by the Pasquini Family. The company's production activities are distributed over three business units (Business to Business, Away from Home, and Consumer), operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural, and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area). Lucart's production capacity exceeds 300,000 metric tpy of paper on 10 paper machines and 58 converting lines. Its consolidated turnover amounts to more than EUR 400 million, with more than 1,300 employees in seven production plants (five in Italy, one in France,+ and one in Hungary).

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. The group serves all of the leading paper producers with customized solutions, relying on the experience gained in more than 60 years of activity.

TAPPI

http://www.tappi.org/