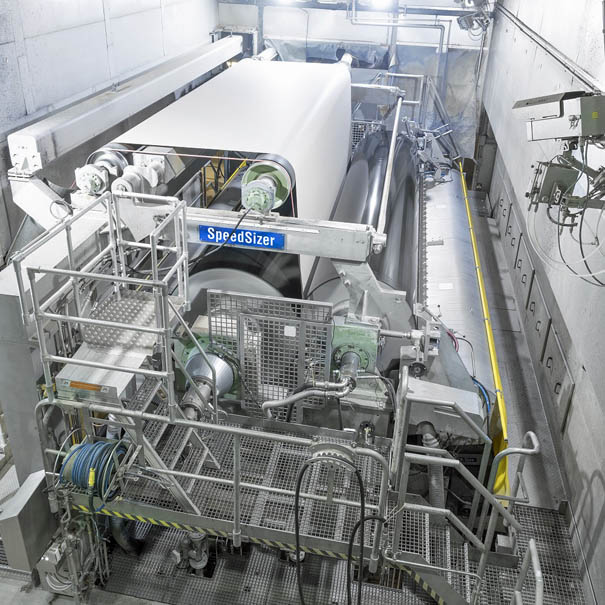

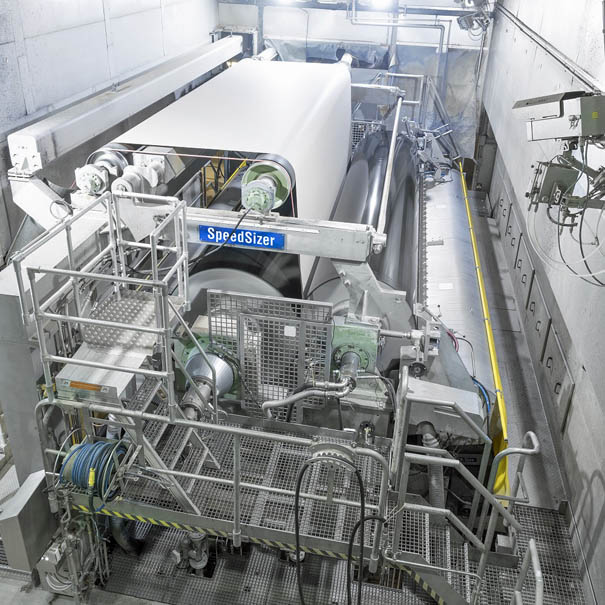

Smurfit Kappa's PM 6 Gains Speed with Voith SpeedSizer AT

A narrow time window, a size press operating at its maximum speed, and the need for greater machine efficiency were all challenges faced by the Voith (Germany) team as it tackled the upgrade of Smurfit Kappa’s PM 6 packaging paper machine at its Zülpich, Germany, mill.

Thanks to excellent planning beforehand, the machine was restarted without problems one day ahead of schedule.

"The startup of the new SpeedSizer has shown how expertise and dedication bring about an excellent outcome. The project simply flew by," said Jochem Meier, manager of operations at Smurfit Kappa in Zülpich.

Smurfit Kappa wanted to achieve a higher production speed through its modernization of PM 6 at the Zülpich mill. The company is one of the leading manufacturers of packaging in Europe. Its Zülpich facility produces premium quality testliner and recycled fluting in basis weights of 100 to 150 gsm from 100% recovered paper.

Because the machine was only supposed to be shut down for a week for the conversion, detailed advance planning was absolutely essential for the success of the project. The excellent longstanding relationship between Voith and the customer facilitated this planning. For example, Voith’s service team had previously carried out maintenance on the PM 6 on an ongoing basis. However, the narrow time frame was just one of the challenges.

A key aspect of the project was the puddle-type size press. Equipped with a deflection compensation roll, it allowed an optimum CD profile of the nip load (linear contact pressure) and for a long time had guaranteed the high quality of the paper. But for technical reasons, the size press limited the production speed of the PM 6 to 1,150 m/min. Even though the size press was one of, or perhaps even the fastest in the world, it prevented the machine from being ramped up to the 1,225 m/min. desired by the customer.

This is why Voith recommended installing a customized SpeedSizer AT with the existing Nipco deflection compensating roll system. This application system enables excellent coating and size profiles even at high speeds. Its use increases the operating window of PM 6 and offers Smurfit Kappa more production flexibility. The SpeedSizer ensures an increase in the solids content of up to 17% and reduces the moisture ingress into the paper web. This results in a higher dry content downstream of the SpeedSizer AT, which helps substantially reduce drying energy and achieves much improved paper web running properties.

Voith used a Nipco roll that was already being used in the old puddle-type size press as a deflection compensation roll. Following comprehensive reconditioning, they now also ensure optimum CD profiles and consequently high paper quality in the new machine as well. The re-use of the previous rolls reduced the costs of the upgrade.

The new SpeedSizer AT plays a major role in reducing the energy consumption of PM 6. Immediately, a 15% reduction in steam consumption could be achieved. The specific energy figures are, of course, also improved as a result of the higher production rate. A good startup is extremely helpful, because the completely closed water circuit at SK Zülpich Papier has to be evaporated again after a week of shutdown.

The use of the new UniFilm T applicator roll cover, which is very wear-resistant, ensures good metering rod service life and more efficient production. In the PM 6, they run for more than 400 hr., well above the average for comparable machines.

TAPPI

http://www.tappi.org/