MegaPress R: Premium Roll Covers with Optimum Sheet Release

In Voith’s (Germany) new MegaPress R roll cover, the special micro-roughness of the surface optimizes sheet release.This improves paper quality, reduces the risk of web breaks, and therefore avoids costly unscheduled downtimes. Long service lives also increase machine availability.

With their excellent sheet release properties, the new MegaPress R roll covers are ideally tailored to the production conditions of smoothing presses. In these press systems, the paper web comes into direct contact with the roll surface. A perfect sheet feed from the roll is therefore a key quality feature and basic prerequisite for very good paper quality.

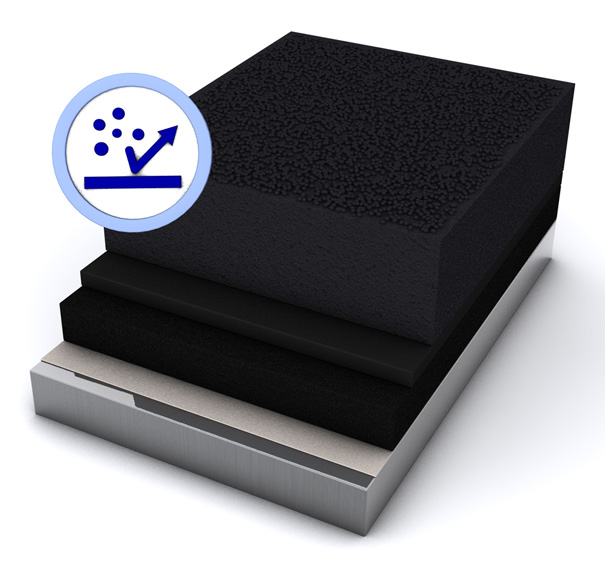

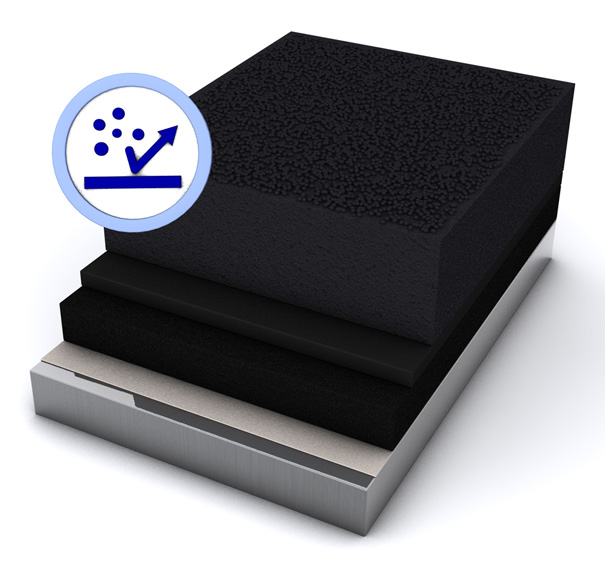

The optimized rubber formulation for the new MegaPress R roll cover (photo above) improves sheet release and is ideal for the production conditions of offset presses.

In the MegaPress R, the micro-roughness of the roll surface ensures that the paper web releases easily from the roll. This lowers the stress on the paper, reducing the risk of a web break, and therefore of an unscheduled downtime. The easy sheet release due to the micro-roughness also leads to excellent paper quality as no fibers are torn from the paper. The new structure of the cover also allows particularly effective cleaning by the doctor blade, avoiding deposits on the roll surface and significantly improving the operational reliability of the machine.

But it is not just thanks to the excellent sheet release that the triple-layer roll cover makes production more efficient. Because of their particularly long service lives, MegaPress R covers have to be replaced less often. This increases the availability of the machine and reduces costs. The first roll covers installed at several paper manufacturers in Europe have confirmed these benefits. Manufacturers from the board and packaging segment in particular have responded very positively to the expansion of Voith's roll cover range.

TAPPI

http://www.tappi.org/