Domtar Presents Profile of Engineered Absorbent Materials Business

When it comes to absorbent hygiene products, what you can’t see is often the most important part. Domtar subsidiary Engineered Absorbent Materials (Jesup, Ga., USA), also known as EAM, produces highly absorbent cores that are hidden inside what other companies produce. So, even if you haven’t heard of EAM, you’ve probably benefited from its absorbent technology, the company explained in a promotional release from Tuesday (Oct. 16, 2018).

Located in southern Georgia, EAM is a hotspot for innovation and product development. Its client list includes some of the world’s largest and most successful consumer product manufacturers.

Lee West, global VP of procurement and IT at Domtar Personal Care and GM of EAM, said, "Domtar has made significant investments in EAM since it was acquired in 2012. This has allowed us to grow and continue to innovate for our customers. Locally and globally, we have a lot to be proud of."

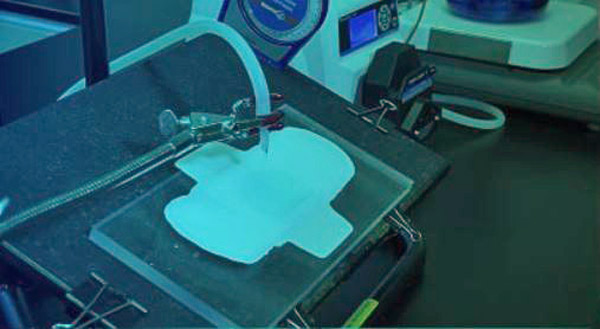

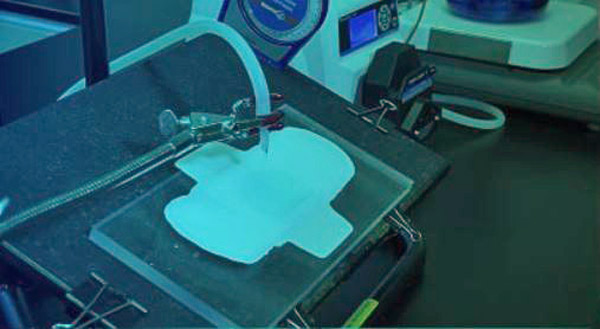

EAM manufactures high-quality absorbent cores that are used for many applications, including baby diapers, food packaging, medical and healthcare solutions, feminine hygiene and adult incontinence. Thanks to their exceptional flexibility, thinness and super absorbency, EAM’s absorbent cores help ensure dignity, health and comfort for millions of people. Such high-quality products are the hallmark of a company that continually pushes the limits of absorbent materials technology.

Paul Ducker leads research and development at EAM. His name appears on several process and product patents, along with the names of other scientists and engineers at Domtar. In fact, collaboration is critical to the team’s success. Ducker, senior research scientist at EAM, helped design and refine absorbent materials. One notable partner is Harry Chmielewski, a senior research scientist who works in the Domtar research lab in Raleigh, North Carolina.

"Harry was the lead inventor on our multilayered laminate core (MLC), one of our recent patented innovations," Ducker said.

Constructed of ultra-thin layers of different absorbent materials, the MLC improves fit, decreases leakage, reduces package size and allows for more efficient use of raw materials. "It’s as soft and flexible as a paper towel, with multiple benefits for the customer," Ducker said. "I’m proud to have contributed to this technology."

EAM’s absorbent materials are sold under two brand names: NovaThin® and NovaZorb®. The secret to the company’s success, it said, is its ability to customize its absorbent cores for a variety of applications to meet customers’ specific needs.

Lori Venn, EAM’s vice president of sales and marketing, pointed out that it’s not only the variety of end uses that drives innovation, but also the breadth of markets. "We have customers across six continents — everywhere except Antarctica," she said. "Much of the innovation we do is in collaboration with our clients. We don’t make an off-the-shelf product."

Plant Manager Kim Sumner agreed, noting how well EAM aligns to Domtar’s values of agility, caring and innovation. "We’re a small company — roughly 70 people — but we can put together any kind of product in response to customer needs. We’re not scared of change. On the contrary: We’re always looking to try something new."

TAPPI

http://www.tappi.org/