Over the Wire

TAPPI

Domtar Corp., Montreal, Que., Canada, and Canada-based FPInnovations this past week announced that they have formed a new joint venture company to build the world's first 1 metric tpd commercial-scale nanocrystalline cellulose demonstration plant at the Domtar Windsor, Que., pulp and paper mill site. Construction will begin in the coming weeks and will take approximately 20 months to be completed.

Nanocrystalline cellulose is a renewable, recyclable, and abundant nanomaterial made of cellulose fibers from the wood pulp manufacturing process. Potential applications include optically-reflective films, high-durability varnishes, and innovative bioplastics. Domtar notes that the properties of this material will provide new opportunities in a wide range of applications for a variety of sectors and markets such as the aerospace, automotive, chemical, textile, and forestry industries. There are promising applications for the aerospace industry that will complement Quebec's innovative aerospace "green" aircraft program, the company adds.

"As the leader in our industry, we are very excited to explore new frontiers by bringing together our operational expertise and the technical knowledge of FPInnovations for the efficient manufacture of this innovative and renewable product," says John D. Williams, president and CEO of Domtar. "The remarkable properties of nanocrystalline cellulose and wide range of potential applications speak volumes about the commercial potential of new fiber-based products that go beyond traditional pulp and paper applications."

Pierre Lapointe, president and CEO of FPInnovations, adds that "this is an important milestone cumulating more than 15 years of R&D investments towards the future development of fiber-based products for the industrial world. During this time FPInnovations developed an extensive intellectual property portfolio around the manufacturing and application of nanocrystalline cellulose. I am confident that this partnership and the strong support of both governments will lead to exciting and successful new commercial applications."

The cost of construction of the demonstration plant is approximately C$32.4 million and operating costs are estimated at C$8.4 million, for a total investment of C$40.8 million. C$12 million of Domtar's total contribution has been submitted for funding approval under the Government of Canada's Pulp and Paper Green Transformation Program. Natural Resources Canada and Quebec's Natural Resources and Wildlife Ministry are contributing C$10.2 million each to FPInnovations' portion of the funding of this project..

During the construction phase, the project will provide approximately 50 jobs as well as engineering services from the Quebec and the Canadian engineering firms, Teknika and Noram, respectively. Approximately 10 permanent positions will be needed to operate the demonstration plant. In addition, numerous researchers and scientific personnel have been and will continue working to deliver on the potential new nanocrystalline cellulose applications and products.

Following the construction phase, under the joint venture agreement, Domtar and FPInnovations will explore the commercial viability of the production of nanocrystalline cellulose on a larger commercial scale.

The development and impact of this new demo plant will be analyzed and discussed in detail, together with other nanocyrstalline cellulose (NCC) and nanofibrillar cellulose (NFC) breakthrough trends and developments, at the 2010 TAPPI International Conference on Nanotechnologies for the Forest Product Industry, September 27 - 29, in the Dipoli Congress Centre, Espoo, Finland. TAPPI’s annual Nanotechnology conference focuses on bringing the newest advances in the field to the technical program, promoting the versatility and promise of cellulose-based nanomaterials, and offering the technical community networking opportunities to advance development of these promising technologies. More information about this event is available online. .

|

Net Impact, San Francisco, Calif., USA, this week announced the winner for a case competition with International Paper, Memphis, Tenn., and Staples Inc. After a competitive application process, three finalist teams created strategic plans for recovering more paper and packaging from underserved markets, including large, multi-tenant locations, company campuses, and universities. Students from Blekinge Institute of Technology, located in Karlskrona, Sweden, submitted the winning strategic plan. The other finalist teams included Columbia University's School of International and Public Affairs and the Stephen M. Ross School of Business and the School of Natural Resources & Environment at the University of Michigan. Since February, the three finalist teams have been working with key leaders at International Paper and Staples to answer questions and review the progress of their strategic plans. The Blekinge team proposed solutions for increasing the efficiency of paper recovery, branding the program, and communicating real-time recovery rates for the companies. "The competition was a great way to practically apply the theories, frameworks, and methodologies of our Master's program in Strategic Leadership towards Sustainability," said Lea Thuot, a student at the Blekinge Institute of Technology and member of the winning team. "The program we presented to International Paper and Staples should allow them to increase paper recycling in the U.S. and assist the paper industry to meet future targets for paper recovery." Staples and IP are currently considering ways to integrate elements of the Blekinge team's plan into their existing program to recover more renewable paper products and put them back to use. ##SHARELINKS##

|

|

ZELLCHEMING-Expo 2010, Wiesbaden, Germany, June 29-July 1, closed on a strong note of optimism and satisfaction among exhibitors as well as visitors. Altogether, 252 exhibitors from 18 countries presented their products and services in an exhibit area of about 8,000 square meters. Despite the global economic situation, exhibitor participation and total exhibit space declined only about 12%, considerably less than previously predicted. Some 36% of exhibitors were foreign, which was near the 2009 level. A total of 3,114 visitors attended the event during its three days, representing a 5% growth over 2009. The number of foreign visitors remained at 24%-plus. The lectures program at 2010 ZELLCHEMING covered current and trend-setting topics, offering the opportunity for intensive, in-depth discussions. The event ended with the traditional ZELLCHEMING Summer Evening, as well as the VDMA and Finland Reception. The online exhibitor list can be searched for products and contact data for this year’s exhibitors. Next year’s ZELLCHEMING-Expo will take place June 28-30 in Wiesbaden. ##SHARELINKS##

|

|

Total U.S. kraft paper shipments in June were 134,500 tons, an increase of 10.7% compared with June 2009, and 8,400 tons higher than May 2010, according to the AF&PA, Washington, D,.C., USA, June 2010 Kraft Paper Sector Report released this week. Total inventory was 67,100 tons, 1,100 tons less than last month. Total unbleached kraft shipments were 118,900 tons, up 10.8% compared with the same month last year. Total bleached kraft shipments increased by 9.4% compared with the same month last year, and 8.3% from last month. ##SHARELINKS##

|

|

For the eighth straight month, U.S. containerboard production rose over last year, according to the June 2010 U. S. Containerboard Statistics Report released this week by AF&PA, Washington, D.C., USA. Total production increased 47,100 tons or 1.7% over June 2009. Total production amounts decreased compared with May 2010; however, the average daily production was up 1.6%. Year-to-date 2010 production has increased 10.6% over 2009. The containerboard operating rate for June 2010 rose 6.0 points over June 2009 to 96.7%. As with total containerboard, linerboard production has seen eight months of increases over last year. June’s production level was 2.3% higher than in June 2009. Linerboard production fell compared with May 2010 but the average daily production saw a 1.5% increase. Production for exports decreased 3.9% over this time last year but increased 12.7% compared with May 2010. Linerboard’s June operating rate mirrors the rise, increasing 5.8 points over June 2009 to 96.9%. June corrugating medium production was flat, only increasing 1,100 tons or 0.1% from June 2009. June’s production fell 1.5% compared with last month, but the average daily production showed an increase of 1.8%. Exports reported an increase, posting a rise of 14.5% over same month last year and 1.4% over May 2010. The June medium operating rate of 96.2% showed an increase of 6.4 points over June 2009. ##SHARELINKS##

|

|

Unlike consumption trends in other mature commodity sectors, paper consumption shows little sign of decoupling from economic growth. Paper consumption is projected to grow about 50% by 2010, compared with its demand patterns in 2000. A strong demand for pulp and paper commodities is expected from Asia Pacific and South American countries in particular from 2010 to 2012. A newly released report by Frost & Sullivan, Cape Town, South Africa, titled Production and Investment Forecasts in the South African Pulp and Paper Market, finds that the market earned revenues of $4.73 billion in 2008. The sector invested $477.0 million on capital projects in 2008, and estimates the capital expenditure to be lower at $202.5 million in 2012. "South Africa has an extraordinarily low cost base in terms of fiber production compared with other pulp and paper producing nations," says Frost & Sullivan Industry Analyst James Fungai Maposa. "This is due to the speedy tree growth rate and lower inherent energy costs." A low-cost base gives South African pulp manufacturers a competitive advantage over other pulp producers globally. However, the South African pulp and paper industry is extremely energy intensive and exposed to risks posed by fluctuating energy prices, including those of fuel and electricity. "The energy price rise has contributed to higher operational costs, negatively affecting the overall profitability of the market," explains Maposa. "Additionally, this has been exacerbated by the weak market prices of pulp and paper commodities resulting in a few companies incurring losses during the financial years of 2008 and 2009." To overcome this setback, pulp and paper producers in South Africa should adopt strategies that are focused on increasing self-generation capacities as well as improving energy efficiencies at all production facilities, the report concludes. "With the anticipated revival of the global economy as well as improvements in living standards around the world, certain sectors of the pulp and paper market, particularly chemical cellulose pulp, and coated graphic paper and tissue, are expected to grow steadily in the long-term," concludes Maposa. "This growth in demand is anticipated to contribute towards greater capacity utilization from 2010 and 2012 and a higher production output of the South African pulp and paper industry." For more information about this study, e-mail Patrick Cairns, Corporate Communications, at patrick.cairns@frost.com, with full name, company name, title, telephone number, company e-mail address, company website, city, state, and country ##SHARELINKS##

|

|

Demand for woody biomass, in the form of wood chips, wood pellets and torrified pellets will increase substantially in Europe over the next 10 years, according to the North American Wood Fiber Review, Seattle, Wash., USA. Exactly how much, though, is unclear as the size of the increase depends on policies and subsidies implemented by governments in individual countries within the European Union, the Review adds. The cost of locally sourced biomass on the continent has gone up for many energy plants, resulting in increased interest in importation of wood chips and pellets from neighboring countries or from overseas. The U.S. South is on the top of the list as a long-term biomass supply source for a number of energy companies, the Review notes. This is because the region has a stable supply of pulpwood, a well functioning infrastructure, and competitive wood fiber costs, compared with most other markets in the world. According to the Wood Resource Quarterly (WRQ), Seattle, Wash., only Chile and the Western U.S. had lower softwood pulpwood prices than the U.S. South during the first quarter of this year.. Hardwood wood fiber prices were well below the global average hardwood price index (GHPI). One region in the U.S. South that has drawn much attention lately is the tri-state area of Southern Georgia, Southeast Alabama, and Northern Florida, a wood fiber hotspot profiled in the latest issue of the Review. Within this area, a significant number of new wood-to-energy facilities have been announced, with one major pellet plant already operating. Sited in Northern Florida, Green Circle Bioenergy began operations in early 2008 and is exporting its entire production to energy plants in Europe. Two additional large-scale, export-oriented pellet plants are on the drawing boards. The German company RWE plant in southern Georgia is under construction with plans to commence production in the 3Q of 2011, and Magnolia Biopower has announced plans for its own pellet export plant to also be sited in Southern Georgia. This expanding green energy sector is situated within a stronghold of the traditional southern pulp industry with seven pulp mills within this Southeastern sub-region. The high concentration of wood fiber consumers within a fairly limited area has pushed wood costs higher the past few years. Pine stumpage prices have increased faster in this region than the average price across the South. In the second quarter of this year, prices were more than 50% higher than two years ago. With the expected increase in wood consumption by the energy sector in this sub-region, it is likely that pulpwood costs will continue to be higher in this sub-region than the average for the U.S. South. More information about this report is available online. ##SHARELINKS##

|

|

Total U.S. printing and writing (P&W) paper shipments increased 11% in June compared with June 2009, the eighth consecutive year-over-year (YOY) increase and the sixth double-digit YOY increase, according to the AF&PA (Washington, D.C., USA) June 2010 Printing-Writing Paper Report, Three of the four major P&W grades posted double-digit increases compared with last June, while the fourth was down 1%. U.S. purchases (shipments + imports – exports) of P&W papers also increased in June, up 4% YOY. Total P&W paper inventory levels edged down 2% from May 2010. Additional key findings include:

##SHARELINKS##

|

|

In the global market pulp arena, reports suggest that Russian producer Ilim has offered $150 - $160/metric ton price cuts, Mark Wilde, senior analyst with Deutsche Bank, reports.. In South America, he adds, Arauco has already announced price cuts of $40 – $50/metric ton. While North America and Europe appear stronger, the ripple effects are inevitable. The effects can already be felt in the hardwood markets, with NBHK list prices in July down $15/metric ton and SBHK process down $10/metric ton. NBSK list prices remained flat in July. However, with U.S. spot NBSK prices declining (-$25/metric ton to $850 - $890 net delivered U.S. East), expectations of a rise in producer inventories in June, and sharp cuts in Chinese prices, a decline in prices seem likely, Wilde notes. The key question, he says, is how quickly will producers respond to falling prices? Without black liquor credits, some high cost U.S. mills may react more quickly than in the first quarte of 2009. While inventories still appear to be in a reasonable shape by historical levels, slower summer demand coupled with restarts in Europe and North America, along with the June startup of APRIL’s 1.3 million metric tpy Rizhao, China, mill, suggest that market imbalance is growing. This may further put a downward pressure on prices, Wilde explains. ##SHARELINKS##

|

|

APRIL Fine Paper has ordered a fine paper production line from Metso, Finland, to be installed at the company’s mill in Xin Hui, Guangdong province, China. Startup of the production line is scheduled for the last quarter of 2011. The value of the order is not disclosed; however, Metso notes that a typical market value for this size production line is about EUR 80-120 million, depending on the scope of the delivery. Metso’s delivery of the complete production line for woodfree uncoated paper includes a stock preparation system, a paper machine, two winders, and an extensive automation package. The scope of supply will also include a Metso machine clothing package for the entire production line. ##SHARELINKS##

|

|

Canfor Corp., Vancouver, B.C., Canada, this past week announced that its Howe Sound Pulp and Paper Limited Partnership (HSPP) will sell all of its assets to Paper Excellence B.V. HSPP operates a pulp and paper mill at Port Mellon, B.C., with a production capacity of 400,000 metric tpy of NBSK pulp and 230,000 metric tpy of mechanical papers, and employs approximately 500 people. HSPP is owned by Canfor and Oji Paper Co., Ltd. of Japan. The transaction is subject to customary closing conditions and closing is expected during the third quarter of 2010. Canfor is an integrated forest products company based in Vancouver with Canadian operations in British Columbia, Alberta, and Quebec, and in Washington state, North Carolina, and South Carolina in the U.S. The company produces softwood lumber, oriented strand board (OSB), remanufactured lumber products, and specialized wood products. Canfor also owns a 50.2% interest in Canfor Pulp Limited Partnership, which is one of the largest producers of northern softwood kraft pulp in Canada and a producer of high performance kraft paper. ##SHARELINKS##

|

|

Georgia-Paciific, Atlanta, GA., USA, and the St. Johns River Alliance (Florida) report that they will create a new calendar with photographs reflecting the beauty and character of the St. Johns River. The calendar will contain the works of 15 photographers selected as finalists in a new photo contest to promote beautiful scenes along the St. Johns River. The pictures will be featured in a 15-month 2011 calendar that will be available in September. G-P and the Alliance are asking the public to help select the grand prize winner. All proceeds from sales of the calendar will benefit the St. Johns River Alliance, whose mission is to preserve, protect, promote, restore, and celebrate the St. Johns River as an American Heritage River. The image receiving the most votes will become the calendar’s cover photograph and the winning photographer will enjoy a 4-day, 3-night excursion to Walt Disney World in Orlando. Visit the contest website to view the nearly 300 images and vote. Individuals may vote once each day through August 2. The contest was open to both amateur and professional photographers and photographs must have been taken within the last three years. The Alliance is a not-for-profit organization formed in 2003 as a direct result of the St. Johns River being designated as one of 14 American Heritage Rivers. ##SHARELINKS##

|

|

Metso, Finland, has acquired the service business of Wyesco of Louisiana L.L.C., located in Slaughter, La., USA. The acquired business, employing 30 persons, became part of Metso’s Paper and Fiber Technology segment this past Monday (July 19). The new business is operating under the name Metso Wyesco Service Center. The value of the transaction is not disclosed. ##SHARELINKS##

|

|

SCA, Stockholm, Sweden, this week reported that it is purchasing the Copamex baby diaper business in Mexico and Central America. The purchase price is equivalent to approximately $50 million on a debt-free basis. ##SHARELINKS##

|

|

The Timken Co., Canton, Ohio, USA, this week reported that it is acquiring the business of QM Bearings and Power Transmission, Ferndale, Washington. QM manufactures spherical roller bearing steel housed units and elastomeric and steel couplings used in demanding processes such as sawmill and logging operations. Timken expects to close the transaction by the fourth quarter of 2010. Terms of the deal were not disclosed. The addition of QM aligns with Timken's strategy to expand its penetration in high-performance applications and extend its power transmission capabilities beyond the company's original, core bearing business. The acquisition is part of the company's continuing effort to provide customers with a wider breadth of friction management and power transmission solutions for the life of their machinery. QM's product offering will complement Timken's recently released Type E product line, the company notes, adding that it will strengthen the presence of the Timken brand in the roller housed unit category and provide an additional offering for markets such as forestry, which require high-performance, durable products. "QM is a great addition for Timken, with a solid, value-added product line that extends our portfolio to offer a wider selection of high-performance products for our customers in the process industries," said Chris Coughlin, president of Timken's Process Industries segment. "These units are an excellent fit with our existing product line and Timken's focus on distribution will provide greater opportunity as we extend them further in the global aftermarket channel." QM Bearings and Power Transmission was founded in 1951 as a manufacturer serving area sawmill and logging customers. The company then began to design and manufacture bearings that could withstand the harsh operating conditions common to logging equipment. ##SHARELINKS##

|

|

At the end of June, Wepa Lucca, Italy, completed the rebuild of Tissue Machine No. 1 in Piano della Rocca (Lucca Italy). The rebuild was conducted by Toscotec, Italy, under a tight time schedule of only 10 days shutdown from paper to paper. The Piano della Rocca plant contains a Toscotec sloped wire machine with a grooved, cast iron, 12-ft-dia yankee dryer originally supplied in 1987and rebuilt into a Crescent Former in 2000 by Toscotec. The machine has a paper trim at the reel of 2,750 mm with a max running speed before the rebuild of 1,700 m/min and a maximum production output of 80 metric tpd, with a speed limitation on production of low basis weight. The goal of the project was to increase the machine speed up to 1,900 m/min and improve paper quality as well as runnability. Toscotec’s supply included a headbox revision and upgrade, felt run modification with new felt rolls, new steel yankee dryer (3,660 mm dia TT SYD 12-ft-dia), new creping doctor on the yankee dryer, new machine mechanical drives, new steam and condensate system, new lubrication unit, and a new blind drilled press roll with a bigger diameter than the existing one. The project was handled on a turn key basis by Toscotec, which also provided engineering, erection, commissioning, and startup. During the shutdown, some additional interventions were also carried out by the mill—new building roof, DCS upgrade, boiler plant maintenance, new bridge crane, new air conditioning system for electrical room, and preliminary works for a future stock preparation upgrade. Only one week after startup, the new machine had produced more than 100 metric tpd of high quality tissue. ##SHARELINKS##

|

|

Korsnäs AB, Gävle Sweden, reports that in the 2010 Brand Tracking Survey for Consumer Packaging, conducted by Opticom International Research, Stockholm, Sweden, its consumer packaging brands have emerged as a "contender" in three important markets—France, Germany, and the U.K. Korsnäs scored especially high on quality expectations and performance, which is says is "significant bearing in mind that the main drivers for brand selection are product quality and end-use suitability." The lower scores for Korsnäs were in brand awareness and ranking among brand owners. The forest, pulp, and paper industry has traditionally not been characterized by strong brands, the company notes. However, the survey suggests that brand knowledge is slowly improving. Responding converters not only referred to type of cartonboard and supplier names, but also increasingly to brands. Respondents in the survey were decision-makers with influence on the specification of cartonboard material in market segments such as pharmaceuticals, health care, cosmetics, chocolate and confectionary, food, and wine and spirits. Korsnäs has three integrated mills in Sweden: Gävle, Frövi, and Rockhammar, with a combined production capacity of 1.1 million metric tpy of cartonboard and paper. The company produces virgin fiber-based packaging as well as biofuel pellets at two plants in Latvia. It exports approximately 90% of its products, and has a workforce of some 1,800 employees. ##SHARELINKS##

|

|

The three newest manufacturing lines add 25 jobs and produce molded fiber products sold under the brand EarthChoice Fiber Blend Hingeware. The implementation of this new molded fiber manufacturing process and related customer demand has been so successful that Pactiv is adding additional capacity later in 2010. Pactiv’s new technology allows for precision molding, which results in a lightweight, smooth, strong, high-quality foodservice carryout container. The process allows for finely-molded features such as curves, folds, and precise in-molded closures. Made from a blend of wood pulp fibers from sustainable and renewable resources, EarthChoice Fiber Blend Hingeware is ASTM D 6868 certified, Cedar Grove Composting-approved, and is processed without chlorine. ##SHARELINKS##

|

|

The Paperboard Packaging Council (PPC), Springfiled, Mass., USA, has hired Emily Rae as a member services and marketing associate. Rae will be responsible for coordinating member service activities and assisting in the development of marketing and communications efforts. She is a recent graduate of the Master’s of Fine Arts program in writing at UMass Amherst. She was previously a technical writer for UMass Amherst and a customer service representative for a biotech company in Cambridge, Mass. ##SHARELINKS##

|

|

The life cycle of packaging is usually short but nevertheless intense. After it fulfills its purpose—to attract buyers and protect the product—its job is done. An unfortunate fate, in the opinion of Japanese packaging designer Akiko Aria. As Aria expresses it, "a life of wrapping arouses our sympathy. However beautiful it is, its destiny is to be thrown away." This year, PIDA (Packaging Impact Design Award), France, challenged its participants to find a secondary use for packaging once the original products had been removed. The scope of this year’s PIDA event was widened by inviting the European Institute for Packaging Technology (Esepac) to participate. Esepac joined the other university that had participated previously, IUT in Reims, France. Esepac was the winning institution at an event and award ceremony in Reims in May. Every year, PIDA, a packaging competition sponsored by Swedish paper manufacturer Korsnäs, has a different theme and the brief this year was to give old packaging a new lease on life – in other words, to indentify an alternative purpose beyond its original role. ##SHARELINKS##

|

|

Recycled Paperboard Technical Association (RPTA), Elgin, Ill., USA, reports that Deborah White has been named its new executive director. Prior to joining RPTA, White was SVP and chief legal officer at the Food Marketing Institute (the supermarket industry’s trade association) and an attorney at Keller & Heckman, the law firm that RPTA uses for the Food Safety Protocol. Dave Ruby will serve RPTA as executive director emeritus until October 31. Joanne Arnold and Fran McGowan will continue their tradition of service in their roles at RPTA. Late last month RPTA relocated to a "virtual" office, and its physical office was closed. The The main telephone number for RPTA will remain the same: (847) 622-254, and individual straff members can be reached by pressing: 1 for Debora White, 2 for Joanne Arnold, 3 for Fran McGowan, and 4 for Dave Ruby. E-mail addresses are as follows: eborah White (dwhite@rpta.org), Joanne Arnold (jarnold@rpta.org), Fran McGowan (fmcgowan@rpta.org), and Dave Ruby (druby@rpta.org). RPTA’sne mailing address is: Recycled Paperboard Technical Association, PO Box 5774, Elgin, IL 60121-5774. To send a package, please contact the appropriate RPTA staff member for a street address. ##SHARELINKS##

|

|

Caraustar Industries, Inc. will increase prices by $40 per ton on all coated recycled paperboard grades produced by its mills, including Britone Newsback, Pearlback, Freezetone, and Whitone. The increase is effective with shipments on and after August 16. Caraustar is one of North America's largest integrated manufacturers of 100% recycled paperboard and converted paperboard products. It serves the four principal recycled boxboard product end-use markets: tubes and cores, folding cartons, gypsum facing paper, and specialty paperboard products. ##SHARELINKS##

|

|

Graphic Packaging International (GPI), Marietta, Ga., USA, , a subsidiary of Graphic Packaging Holding Co., this week announced a price increase of $50 per ton on its SUS coated unbleached kraft paperboard, effective with shipments on or after August 23. The increase affects GPI's coated folding carton grades, Pearl-Kote and Omni-Kote, as well as the Aqua-Kote carrier grade ##SHARELINKS##

|

|

Glatfelter, York, Pa., USA, this week announced the hiring of Jonathan Bourget as VP and GM of its Advanced Airlaid Materials Business Unit (AMBU), effective the beginning of this week. Bourget will have overall responsibility for the global AMBU organization, setting direction and implementing strategy to deliver critical business objectives. In making this announcement, Dante Parrini, executive VP and COO, said that, "with a proven track record in global integration, aligning strategy and resources with business objectives, Jonathan also brings valuable experience in the manufacturing and marketing of engineered nonwoven fabrics and products to our organization. We look forward to his leadership and to realizing the benefits of the growth opportunities in this business unit." Bourget has led operations in Canada and throughout Europe, including the Netherlands, France, Switzerland, Romania, Spain, and Italy. He comes to Glatfelter from Polymer Group Inc. (PGI) where he served as VP and GM for European operations. Prior to working at PGI, Bourget served as interim president at IVACO Rolling Mills in Montreal, Que., Canada, and in various leadership roles at ALCOA, bringing more than 15 years of experience in building highly effective teams and delivering results within public and private companies. ##SHARELINKS##

|

|

The early-bird registration for the TAPPI Extrusion Coating Course ends Tuesday, July 27, 2010. You'll want to be in Charleston, South Carolina USA August 24-26, 2010 to network with your peers and a distinguished group of industry veterans as they explore best practices and equipment technology that apply to extrusion coating applications. This three-day course includes a 4-hour Paper and Board Manufacture and Properties Workshop led by Chuck Klass, Klass Associates Inc. This course is ideal for extrusion engineers, supervisors and operators; technical directors and superintendents, technical assistants and R&D personnel. To learn more, or to register, visit www.tappi.org/10extru. ##SHARELINKS##

|

|

Designed to help you learn 'why' things happen on a paper machine, the 2010 TAPPI Paper Machine Operations Course is a three-day course, to be held in Norcross, Georgia USA on August 24-26, 2010. The course will focus on improving your understanding of the overall paper machine operation and improving paper machine operations and product quality. Participants of this course will gain an improved understanding of the overall paper machine operation. In addition, a fundamental understanding of fiber properties and the way the mechanical components function on the paper machine will give the participant the tools needed to more quickly troubleshoot operational problems and improve paper machine operations and product quality. After successfully completing this course, participants should be able to: • Describe how the mechanical components and operations of the paper machine affect the structure of paper and thus the quality. • Identify design and operating features of the paper machine that affect machine performance. • Identify ways to improve paper machine efficiency and product quality based on a new understanding of the overall operation. To learn more about this course and to register, visit the online course information. ##SHARELINKS##

|

|

The TAPPI Introduction to Kraft Pulping and Bleaching Course -- August 9-10 -- covers in only two days the introductory elements of four other excellent more in-depth TAPPI courses on the same topics. This course will be held at the Kemira Training Room in Kennesaw, Georgia, and will help you: • Expand overall understanding of kraft pulp mill operations and bleaching processes • Broaden awareness of how one part of the process affects other operations • Demonstrate the affect of processes on kraft pulp quality • Build confidence for effective interaction among experienced process engineers and operators • Help you troubleshoot product quality problems Why should your boss send you? This course offers a fundamental overview of kraft mill fiber line operations. It’s perfect for anyone new to the kraft pulping processes, particularly engineers and operators. View the Preliminary Course Schedule developed by instructor Dr. Michael Kocurek, one of the most recognized educators in the paper industry. He has taught undergraduates, graduates, and in-mill courses for more than 3,000 industry professionals and operators for over 50 paper industry corporations and government agencies. Register soon. Secure your seat before July 28 for an early-bird savings. ##SHARELINKS##

|

|

The TAPPI Introduction to Tissue Manufacturing course is scheduled August 11-12 in Kennesaw, Ga. If you register by July 28, you'll get the early-bird discounted rate to secure your seat! This course is ideal for anyone who could benefit from an introductory- to intermediate-level course on tissue. The content can help build confidence for more effective interactions with others on the job like operators, technical staff, researchers, suppliers and customers. It also enables those who attend to: - Contribute more toward improved tissue manufacturing operations - Play a stronger role in producing better, more competitive products You'll learn from one of most distinguished professionals in the industry! Dr. Michael J. Kocurek, PhD, Professor Emeritus at North Carolina State University, is the course instructor and has taught this curriculum to multiple corporations and mills. He is a TAPPI Fellow and has taught TAPPI’s oldest and highly ranked short course on Introduction to Pulp & Paper for more than 37 years. In 2005, he was inducted into the Paper Industry International Hall of Fame, an honor bestowed on those who have made preeminent contributions to the global pulp & paper industry. ##SHARELINKS##

|

|

Nominations for the major TAPPI 2011 awards are due by August 1, 2010. The awards that may be presented in the upcoming year are: • Gunnar Nicholson Gold Medal Award - The Association's highest technical honor may be presented annually to recognize an individual or individuals for preeminent scientific and engineering achievements of proven commercial benefit to the world's pulp, paper, board, and forest products industries and the other industries that TAPPI serves. • Herman L. Joachim Distinguished Service Award - The Association's highest award for service, may be presented annually to recognize leadership and service which have significantly and demonstrably contributed to the advancement of the Association. • Paul W. Magnabosco Outstanding Local Section Member Award – The highest honor for Local Sections may be presented annually to recognize an individual for outstanding leadership and exceptional service to one or more Local Sections, which have resulted in significant and demonstrable benefits to the Local Section members. • TAPPI Fellow - TAPPI Fellows are Individuals who have been members of TAPPI for not less than 10 years prior to the nomination, and who have contributed meritorious service to the Association and/or the paper and related industries. Retiring members of the TAPPI Board of Directors become Fellows automatically at the end of their term. The TAPPI Awards and Honors page has links to these awards which will show the qualifications required and links to the nomination forms that must be completed. You may submit all nomination forms by email to standards@tappi.org, or you may fax them to the attention of the awards department at +1-770-446-6947, or send by mail to TAPPI, Awards Department, 15 Technology Parkway South, Norcrosss, GA 30092, USA. ##SHARELINKS##

|

|

Covering market trends, manufacturing processes and cost reduction, technology and applications, innovations in printed electronics and sustainability and life-cycle analysis, the 2nd annual Specialty Papers Conference, November 10-11, 2010 in Chicago, Ill. is USA is a can't miss event for anyone in the specialty paper industry! In addition to the in-depth coverage of the most important issues to the industry, Specialty Papers 2010 will offer many opportunities to network. Nearly 150 key industry leaders attended TAPPI’s and Pira International's inaugural event last year! Visit www.specialtypaperconference.com to view the list of confirmed speakers. ##SHARELINKS##

|

|

The TAPPI Board of Directors will consider amendments to Article IV and Article VIII of the TAPPI Bylaws at its upcoming meeting. In accordance with the Bylaws any proposed amendments must be provided to the membership for comment thirty (30) days prior to action by the Board of Directors. The proposed amendments include: • Removing the 60-day postal notification period for those members who have been suspended. • Modifying the Nominating Committee composition to add one local section officer and one division officer. • Placing a term on Nominating Committee service of no more than three consecutive years or terms. For more information on the proposed amendments please go to www.tappi.org/2010bylawchanges. Comments are due on or before August 20, 2010. Please contact Mary Beth Cornell at +1 770-209-7210 or mcornell@tappi.org with questions. ##SHARELINKS##

|

|

The TAPPI Research Management Committee requests your nominations for the Research and Development Technical Award and the William H. Aiken Prize. The award is presented for outstanding accomplishments or contributions that advanced the technology of the paper and related industries. More specifically, they should be in the field of research and development. The nomination should contain: * A summary of the nominee's technical achievements * The impact and relevance of the research on industry * Education, work history * Examples of the impact that they have had on others * Other pertinent activity such as involvement in TAPPI The $500 prize is funded by an endowment from the estate of William H. Aiken, TAPPI president in 1967-1968. He was vice president of technology for the former Union Camp Corporation at the time of his death in 1974. Dr. Aiken also won the TAPPI Gold Medal, the association's highest honor, in 1971. Nominations for the Research and Development Technical Award and the William H. Aiken Prize should be submitted by August 1, 2010, to David Bell dbell@tappi.org at TAPPI, 15 Technology Parkway South, Norcross, GA 30092, USA, or fax +1 770-446-6947. ##SHARELINKS##

|

|

August 3-5 August 9-10 August 11-12 August 17-18 August 24-26 August 24-26 ##SHARELINKS##

|

Korsnäs points out that the survey clearly shows a positive development of its brand in recent years. This is a result, it says, of won contracts, a reputation for an ability to deliver, cooperation with European universities, and massive market communication efforts. In addition, the company notes, the Korsnäs brand has drawn a great deal of attention at trade fairs such as Luxe Pack in Monaco, with several hundred new business contacts as a result. In the photo on the right, the Korsnäs "Cone" was introduced at Luxe Pack 2008 as a symbol of the utmost refinement of forest products, and a showcase for print effects.

Korsnäs points out that the survey clearly shows a positive development of its brand in recent years. This is a result, it says, of won contracts, a reputation for an ability to deliver, cooperation with European universities, and massive market communication efforts. In addition, the company notes, the Korsnäs brand has drawn a great deal of attention at trade fairs such as Luxe Pack in Monaco, with several hundred new business contacts as a result. In the photo on the right, the Korsnäs "Cone" was introduced at Luxe Pack 2008 as a symbol of the utmost refinement of forest products, and a showcase for print effects.  Pactiv Corp., Lake Forest, Ill., USA, this week announced that it has completed the first three phases of a $14.5 million project to produce high-quality molded fiber hinged lid carryout containers and other products at its Moorhead, Minn., facility. Initial production commenced early in 2009 and the project is expected to be fully operational by October 2010.

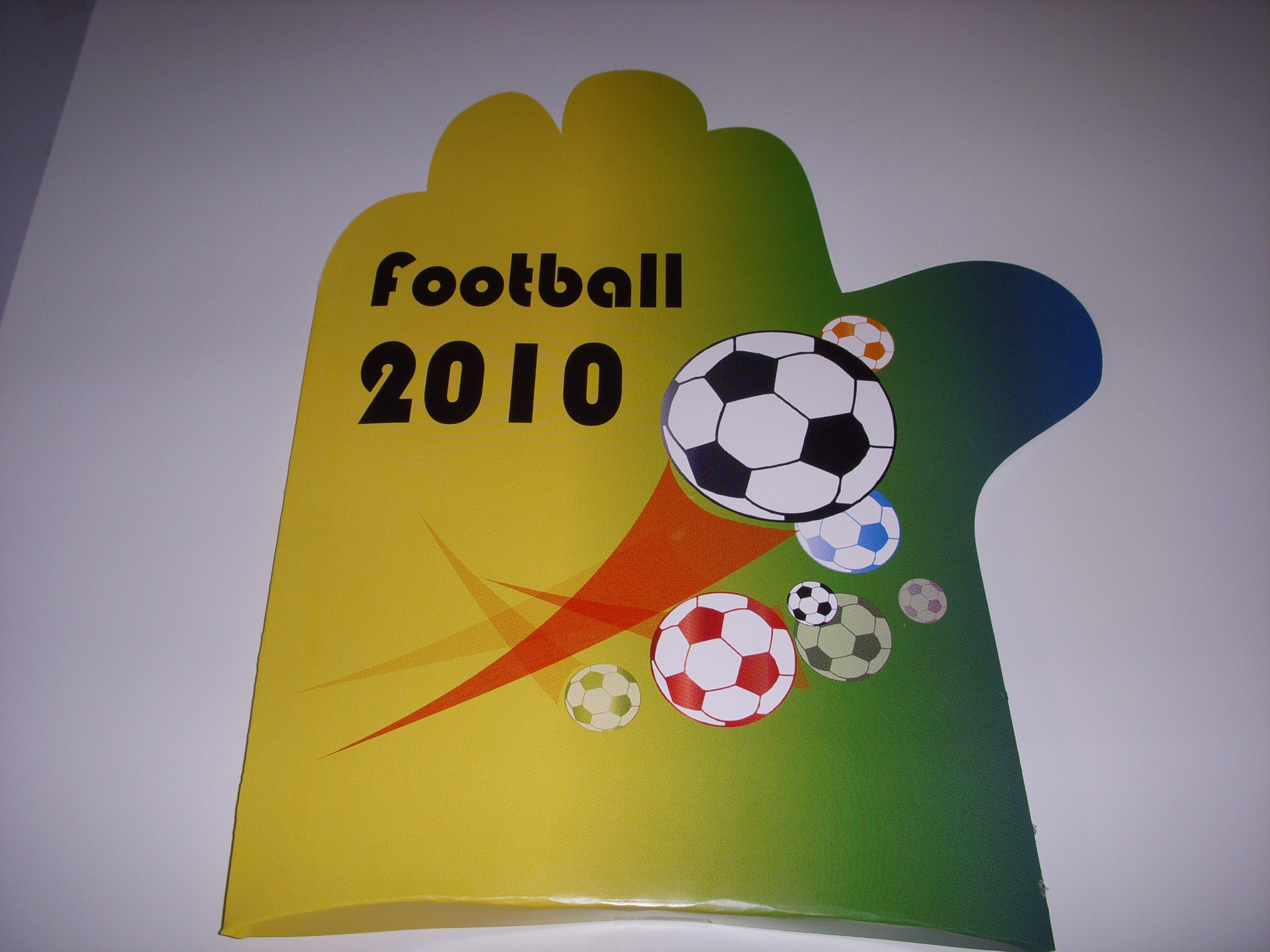

Pactiv Corp., Lake Forest, Ill., USA, this week announced that it has completed the first three phases of a $14.5 million project to produce high-quality molded fiber hinged lid carryout containers and other products at its Moorhead, Minn., facility. Initial production commenced early in 2009 and the project is expected to be fully operational by October 2010. The first place winner this year, "Hands Up (see photo on the right)," was a package in the shape of a hand for a football club t-shirt. The concept was based around the FIFA World Cup in South Africa. The t-shirt was designed for the supporters of the French team. Wearing the t-shirt and waving the "hand" creates the perfect atmosphere and demonstrates team spirit. "Brilliantly simple," according to the jury. "Being one and the same, the packaging and intended message have an immediate effect."

The first place winner this year, "Hands Up (see photo on the right)," was a package in the shape of a hand for a football club t-shirt. The concept was based around the FIFA World Cup in South Africa. The t-shirt was designed for the supporters of the French team. Wearing the t-shirt and waving the "hand" creates the perfect atmosphere and demonstrates team spirit. "Brilliantly simple," according to the jury. "Being one and the same, the packaging and intended message have an immediate effect."