Over the Wire

TAPPI

|

Sappi notes that when it decided to launch an initiative to build a school in Haiti, "no one could have predicted the amount of support the project would receive from printers. Not only did they purchase Sappi fund raising paper but also donated their own money to the cause and in doing so demonstrated the power of partnership." Money raised by Sappi paper sales will help to fund buildings where children will receive education, hot meals, and a clean water supply. "It will give the children of Haiti the quality of care and learning support they so rightly deserve," Sappi points out. The company will provide customers with important updates on the school and the project through its Ideas That Matter website and through the. Stichting Naar School in Haiti Foundation website. Eric Van den Bruel, business development and marketing communications director at Sappi, says that "We couldn’t have got this far without the enthusiasm and support of our clients who have participated in the project. It is an incredibly worthwhile cause and one that has touched everyone. We would like to say a big thank you and will do everything we can to provide progress reports as things develop." ##SHARELINKS##

|

|

SCA Tissue North America recently dedicated four new wind turbines at its Service Excellence Center (SEC) in Menasha, Wis., USA, with a community green fair and a ceremony attended by business, union and political dignitaries. At the ceremony, Roberta Gassman, secretary of the Wisconsin Department of Workforce Development and a member of Governor James Doyle’s cabinet, noted that the wind turbines were the first produced by an Oshkosh, Wis., startup company called Renewegy LLC. The project brought together several local businesses, and has helped create and sustain the kind of green jobs that the state and national economy need, she said.

Lewis added that the company recycles more than 750,000 tons of wastepaper each year in making its Tork products from 100% recycled fiber. "To put that into perspective," he said, "it’s enough to cover Lambeau Field in Green Bay, Wis., 233 times, including the end zones, 3 ft. high in wastepaper." The wind turbines (pictured below) are the latest in a series of ongoing environmental, conservation, and alternative energy initiatives at the SEC. In 2008, for example, SCA Tissue installed 115 solar panels on the roof of the SEC. Together, the wind turbines and solar panels will deliver an estimated 2 to 2 ½ months of the facility’s annual electrical power needs.

##SHARELINKS##

|

|

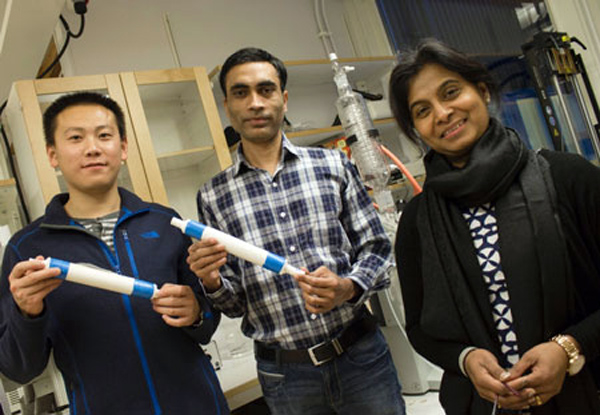

This past Monday, power was first applied to the new low-consistency (LC) refiner system donated to the Pulp and Paper Centre at the University of British Columbia (UBC), Vancouver, B.C., Canada, by Advanced Fiber Technologies (AFT), Montreal, Que., Canada. The startup marked another milestone in the University’s research program to enhance paper quality and reduce energy consumption. It also marked a milestone in what has been described as one of the longest industry/academic partnerships at the university (more than 25 years), according to James Olson, a professor in the Mechanical Engineering Department at UBC and a member of the Advanced Papermaking Initiative. AFT contributed the key process equipment to enable UBC to expand its capabilities in LC refining—a technology that is now being exploited by the world’s leading papermakers to "significantly improve the energy efficiency of mechanical pulp production" according to Olson. "We are now starting up the most state-of-the-art, university-based LC Refining Facility in the world," Olson continues. "We are grateful to AFT for helping us move into this important research area." Prior to the donation by AFT, the University had no industrial LC refining equipment. "We attempted to retrofit a high-consistency refiner to operate at LC, but this was unsuccessful," Olson says. A member of the Aikawa Group, AFT designs and manufactures screening components and FINEBAR refiner plates for the worldwide pulp and paper industry. The donation to UBC included a state-of-the-art 16-in. Aikawa AWW single-disc LC refiner plus FINEBAR refiner plates to process a full range of hardwood, softwood, and recycled fibers. The Natural Sciences and Engineering Research Council of Canada (NSERC) provided funding to purchase ancillary equipment, and West Fraser Mills in British Columbia donated a 150 hp motor to drive the refiner. "AFT has consistently contributed to R&D to fully understand the science of screening," says Dr. Robert Gooding, VP of Technology at AFT. "This most recent contribution underscores our commitment to LC refining research." Gooding explains that while LC refining remains essential to a wide range of papermaking applications, it has taken on a new level of importance for mechanical pulping due to its reduced energy requirements. "AFT FINEBAR has been at the forefront of low-consistency refiner plate technology so we wanted to be a part of this important project." After a short "learning curve" to understand the complexities and nuances of the new facility, fundamental research and development will begin in earnest. The LC Refining Facility will allow UBC to test new ideas and concepts for pre-treatment, power reduction strategies, advanced controls, and the impact on paper surface qualities. "Of course, we will be eager to perform sponsored research for pulp product development to help the industry further improve its paper products," Olson says. Gooding added that AFT will also utilize the facility for fundamental research on plate geometries and power-gap relationships, as well as supporting customer trials. ##SHARELINKS##

|

|

U.S. production of paper and paperboard declined 10.6% from the prior year to 79.1 million tons, according to a new report issued this week by the AF&PA (Washington, D.C., USA) titled 2009 Statistical Summary of Paper, Paperboard and Wood Pulp. Exports of paper and paperboard retreated 10.9% to 13.8 million tons in 2009. However, imports of these products fell further, down 20.5% from 2008 to 13.4 million tons, resulting in a positive balance of trade for this product segment, "These results reflected the effects of the economic downturn on the paper and paperboard industry in the U.S.," says AF&PA chief economist Dr. Stanley Lancey. "However, paper and paperboard production rebounded 8.6% versus year ago during the first six months of 2010," he added. With exports picking up steam in the first half of 2010 while imports remain subdued, Dr. Lancey says he expects the trade balance to remain positive through the year. ##SHARELINKS##

|

|

Analysis of public data by Forisk Consulting, Athens, Ga., USA, indicates a 67% success rate for announced wood-using bioenergy projects in the continental U.S. According to Forisk, projects with the highest probability of success share two requirements. One, they employ currently viable and scalable technology. Two, they demonstrate verifiable progress in planning and executing bioenergy project development. As of July 29, Forisk screened 363 announced and operating wood-consuming bioenergy projects. These projects represent potential, incremental wood use of 121 million green tons per year by 2020. Based on Forisk's screening methodology, projects representing only 68.4 million green tons per year pass basic viability screening. "Why is this important? Because assessments of emerging wood bioenergy markets in the U.S. that assume all projects succeed overstate likely wood use for energy by nearly 77%," says Brooks Mendell, president of Forisk. "Clearly, tracking and screening bioenergy projects challenge those interested in renewable energy investments, economic development, and timberland markets. Wood Bioenergy U.S. and Wood Bioenergy are two new subscription products from Forisk that can help solve this challenge." In Wood Bioenergy U.S.,"we continuously confirm, in a systematic way, that each project is moving forward and getting closer to being operational," says Amanda Lang, managing editor. The current issue indicates that bioenergy projects in the South comprise the largest volume of potential wood use of the three U.S. regions, but the lowest pass rate through Forisk's screening. Southern projects representing 24 million tons (a 40% pass rate based on volume) appear viable based on current analysis. Alternately, the U.S. North, which includes Appalachia, the Lake States and the Northeast, has the largest number, with 153 projects announced. More information is available online (click on "Bioenergy"). ##SHARELINKS##

|

|

Ahlstrom Group, Helsinki, Finland, a manufacturer of nonwovens and specialty papers, announced this week that it has partnered with Eureka Forbes Limited to launch a new product to serve the growing needs for clean water in the Indian sub-continent. The device, designed and manufactured by Eureka Forbes, which will be sold under the brand name AquaSure, incorporates Ahlstrom's Disruptor filter media, a technology that removes a wide range of pathogens and submicron contaminants from water. The new AquaSure storage water purifier removes all three types of contaminants from water: physical, chemical, and microbiological - without the use of any chemicals and, thus, gives not just microbiologically pure, but safe drinkable water. The new technology eliminates the need to add disinfecting chemicals that raise potential public health and safety concerns. In addition, it provides a simple, convenient and affordable way to purify water, consistent with entrenched consumer habits, according to Ahlstrom..

##SHARELINKS##

|

|

Celulosa Arauco y Constitucion SA, Chile, is developing plans for a new pulp mill in Uruguay, according to a Fox Business report this week. Arauco reportedly will develop and operate the mill through a joint venture with Stora Enso of Finland. Arauco, a subsidiary of fuel and forestry conglomerate Empresas Copec SA, would have access to as much as 50% of the mill’s production, while Stora Enso would have access to the rest, according to the news report. The new mill would cost some $500 million and would have a production capacity of 1.3 million metric tpy. Production would be aimed primarily at Europe, but other export markets are expected to develop due the facility’s large production capacity. Technical studies and government work are currently underway for the expansion project, which will be presented to Arauco’s board of directors by year’s end. ##SHARELINKS##

|

|

Appleton, Appleton, Wis., USA, reports that its paper mill in West Carrollton, Ohio, has returned to full production following repair work and the installation of temporary boilers to address damage caused by the collapse of some internal structures of a coal silo at the mill. The incident occurred on July 10 and caused no injuries. Portions of the mill returned to production on July 12 and continued to operate while repairs were underway. Appleton quickly shifted production of some of the carbonless and thermal paper products produced at the West Carrollton mill to the company’s manufacturing facilities in Appleton, Wis., and Roaring Spring, Pa., to minimize the impact of the incident on its customers. The company notes that it will continue to leverage the strength of its network of manufacturing facilities to return order lead times and service performance to normal levels over the next few weeks. Appleton produces carbonless, thermal, and security papers and Encapsys products. It has manufacturing operations in Wisconsin, Ohio, and Pennsylvania, employs approximately 2,000 people, and is 100% employee-owned. ##SHARELINKS##

|

|

Enviva Pellets, Richmond, Va., USA, a manufacturer of wood pellets and processed biomass fuel in the U.S. and Europe, announced this week that it has acquired CKS Energy Inc, Amory, Miss., a privately held company that manufactures wood pellets for industrial, commercial and residential uses. CKS is one of only a few U.S.-based companies with a successful track record of manufacturing and exporting sustainable, high-quality wood pellet biomass fuel for utility customers, many of whom are based in Europe where the use of wood pellets is well integrated into all areas of the energy sector. In the coming months, Enviva intends to hire additional staff for the facility, which will be known as Enviva Pellets Amory, and expand its production from a current capacity of approximately 50,000 tons to more than 100,000 tons a year. The facility will primarily service Enviva’s long-term European customers, and raw biomass materials will be sourced locally. "As we continue to increase our U.S. manufacturing footprint, we are particularly excited about this acquisition. Strategically, CKS is an excellent fit, providing Enviva with a robust and stable fiber supply chain and easy access both to our key European customers as well as to customers in the upper Midwest," Enviva Chairman and CEO John Keppler said. "Through this acquisition we look forward to increasing our production of sustainably manufactured wood pellets to meet increasing demand from utilities, power companies, businesses, and consumers in Europe and the U.S." ##SHARELINKS##

|

|

The Sustainable Green Printing Partnership (SGP), Loveland, Ohio, USA, reports that DuPont Packaging Graphics, Wilmington, Del., and Mohawk Fine Papers, Cohoes, N.Y., recently upgraded their SGP level from silver to gold. SGP notes that "the continued support of these industry-leading companies demonstrates both their commitment to sustainability in the graphic communication industry and their belief in SGP's role in facilitating this endeavor." Patron sponsorships, SGP explains, keep certification fees low for printers, enabling the printers to focus on measuring and improving their environmental performance. "We are excited to see these leading companies continue their sustainability journey with the SGP Partnership. Each of these businesses understands the importance of sustainability in today's marketplace and has chosen to support the SGP Partnership' leadership role of setting sustainability benchmarks for the graphic communications industry. With the synergies of like-minded organizations working together, sustainability certification is growing to become an adopted standard in the graphic communication industry," Marcia Kinter, SGP Board of Directors chair, said. DuPont Packaging Graphics is a global supplier of flexographic printing systems in digital and conventional formats. Mohawk Fine Papers, a third-generation, family-owned business and certified Women-Owned Business Enterprise, produces premium papers for sheetfed, web, and digital presses. ##SHARELINKS##

|

|

NewPage Corp., Miamisburg, Ohio, USA, this week reported that it has been honored by the HP Indigo Preferred Media partner program with a two-year extension of its preferred partner status. NewPage has now earned this status partner four years in a row. As a preferred partner, NewPage has achieved a higher level of collaboration with HP Indigo, going beyond substrate certification and including a commitment to ongoing product development and go-to-market cooperation, the company notes. Dennis Essary, director of digital papers at NewPage, explains that brands "are manufactured with proprietary coating formulas and optimized for top performance on HP Indigo digital presses. All of our digital papers for HP Indigo are certified by the Rochester Institute of Technology to meet the stringent requirements for runnability, ink transfer, adhesion, image quality, and blanket life." ##SHARELINKS##

|

|

Sappi Fine Paper North America, Boston, Mass., USA, this week announced that a public auction will be held September 29 by LiquiTec Industries, in association with Can-Am Machinery, to sell the assets from Sappi’s permanently closed coated paper mill in Muskegon, Mich. Equipment from the Muskegon pulp mill, paper mill, and converting facility, will be for sale. Primary assets up for bid include a 174-in. wire width paper machine wet end, 2004 Bielomatik folio ream wrapper, Jagenberg Synchro 86" folio sheeter, Jagenberg converting complex sheeter and ream carton packaging line, Voith pulper, and a MSK/Covertech automatic shrink wrap skid carton line. A full list of the Muskegon Mill assets up for bid is available online. For additional information regarding the auction, contact Cate Giltner with LiquiTec Industries at 800-852-9252. ##SHARELINKS##

|

|

SCA, Stockholm, Sweden, says it is determined to become the first retail supplier in the Netherlands to distribute all of its retail hygiene products in a 100% CO2--neutral way. To this end, a collaboration project named Green Care Transport has been started with a selected group of transporters. "The primary aim of the collaboration is to reduce the CO2 emissions for all transport by using reduction targets, a program of action for transporters, and by investing in sustainable energy projects," says Riny Strik, regional director of business logistics for SCA’s hygiene operations in the Benelux, and the man who came up with the concept. "We would like to encourage more transporters, suppliers, and retailers to start using the Green Care Transport Program," adds Riny. "Now we have CO2 reduction targets and a program of action in place. As part of this program, existing CO2 registration processes will be used to track the activities planned." Included in the program are processes such as the optimization of efficient motors, aerodynamics and driver training, all of which will result in lower fuel emissions and, therefore, lower CO2 emissions. SCA and its transporters will offset the remaining emissions by investing in sustainable energy projects—in collaboration with the Climate Neutral Group and in accordance with WWF’s Gold Standard , such as a windmill park in Turkey or Taiwan, which will make 100% CO2-neutral transport a reality. The new distribution process will have a positive effect on the environment and. additionally, transport costs will drop as a result of the optimization of truck loading and the limitation of unnecessary empty transports, SCA points out. ##SHARELINKS##

|

|

Suzano Papel e Celulose, Sao Paulo, Brazil, plans to invest up to $1.3 billion to create a renewable energy unit to produce and sell wood pellets to European electricity generators. According to Reuters news service, the unit, Suzano Energia Renovavel, would build three timber pellet plants, each having a capacity of 1 million metric tpy, with operations starting between 2013 and 2014. Most likely clients for the wood pellets would be European Union utilities that could use them to meet curbs on carbon emissions. According to Suzano, the amount of resources and time necessary to produce 1 million metric tons of pellets could be less than half of that required to produce the same quantity of pulp. Initial annual revenues are estimated at $480 million, Reuters reports, adding that two facilities could be built between 2018 and 2019 to meet demand. ##SHARELINKS##

|

|

All major North American containerboard producers announced a third $60/ton price increase, effective early this month, "and we expect their box hike to follow," Mark Wilde, senior analyst with Deutsche Bank, points out. Hikes in January and April added $110/ton to domestic list prices. "While industry fundamentals are very favorable (June box shipments +3.7% y/y, high operating rate of 96.7%, and inventories still at 30-year lows), macro indicators (soft employment, easing in ISM index, etc.) suggest that hike No. 3 will be tougher than expected," Wilde says. Permanent capacity reductions of ˜3 million tons since 4Q08 and spring maintenance downtime have tightened markets, Wilde adds, noting that conditions are also tight elsewhere. Smurfit Kappa & Mondi recently announced a EUR 60/metric ton price increase on unbleached kraft linerboard in Europe, effective September 1. European producers have already boosted prices by EUR 150/metric ton ($176/short ton) in 2010. Last week, Mexican producers announced a $40 - $50/ton containerboard price increase, effective August 1, Wilde reports. ##SHARELINKS##

|

|

Document Security Systems, Rochester, N.Y., USA, a developer and manufacturer of security and authentication solutions that prevent counterfeiting and brand fraud, reports that it has been awarded an annual packaging order contract order from Walgreens worth approximately $2.7 million through July 2011, with additional opportunities for non-contract work. The order represents a renewal of an ongoing relationship between Document Security Systems' packaging subsidiary, Premier Packaging, and Walgreens ##SHARELINKS##

|

|

The global corrugated board packaging market is forecast to grow to 98 million metric tpy in 2015, a new study by Pira Internationa, Leatherhead, U.K., reveals. According to the study, the sector is to grow by a CAGR of nearly 5% between 2010 and 2015, with the highest expansion rates forecast in Brazil, Russia, India, and China (the BRIC countries), and Poland. Actual consumption of corrugated board was 77 million metric tons in 2009, with an exconverter value of almost $82 billion. Asia was 44% of total corrugated board production, China was almost 25%, and the U.S. was 20%. Pira expects the overall market to rise 1.2% in 2010 to 78 million metric tons. For the period to 2015, the outlook is more positive with a forecast CAGR of 4.7%, taking the market to 98 million metric tons in 2015. More than 60% of corrugated board is used to package non-food products. The largest single end-use sector is the electrical goods market. Processed food is 25% of the total demand and all food is just under 40%. Pira expects the strongest prospects will be found in personal and household care products, glassware, electrical goods, and chemicals. Processed food will be 25% of incremental volume, over 5 million metric tons of additional demand between 2010 and 2015. In food markets, the BRIC countries offer the most exciting growth prospects, along with Poland and Brazil. Forecast incremental demand in BRIC countries for 2010 - 2015 is 7 million metric tons, with China taking 4 million metric tons. The Future of Corrugated Board Packaging to 2015 offers up-to-date information on the state of the global corrugated board market plus rational forecasts of future demand, broken down by country, print process, end use and other factors. The study also contains an in-depth analysis of the sector in terms of its key players, supply chain, geographic structure, key drivers and the shares of individual uses of corrugated board. ##SHARELINKS##

|

|

Mayr-Melnhof Packaging, Germany, has acquired a 70% participation in Marinetti S.A., located in Santiago de Chile. The former family shareholders hold the remaining shares. Marinetti produces folding carton packaging for multinational as well as local producers of branded goods. Currently the company employs some 650 people and generates annual sales of approximately EUR 45 million. ##SHARELINKS##

|

|

SCA, Sweden, will upgrade the existing Pope reel and purchase a new winder and a new roll transport system for its Munksund Mill in Piteå, Sweden. Voith Paper, Germany, was chosen as the major supplier for these projects. Munksund intends to optimize and automate the entire process from the Pope reel, thus improving both its offering and paper production capability. The 7.1 m wide PM 1 produces kraftliner and white top kraftliner in a basis weight range of 125 to 440 g/m2. ##SHARELINKS##

|

|

Currently, most of SCA’s timber goes to mills that produce pulp, paper, or solid wood products. Residual material is primarily used as fuel. However, researchers believe that the forest will be able to provide a greater number of products in the future, Eriksson and Österberg say. "We will continue to make paper in the future, but our mills will be more developed and be able to utilize more valuable compounds in the wood," Österberg, director of research, notes. The research center is located next to the Mid Sweden University in Sundsvall and employs 85 people. Its job is to uncover what the forest can generate in the future. At the SCA research center, one of the most promising areas relates to nanocellulose. The center recently initiated collaboration with the Borregaard biorefinery, Sarpsborg, Norway, a manufacturer of nanocelluose, to learn more about how nanomaterial can strengthen paper products. As SCA explains, the word nano means one-billionth and gives an indication of the incredibly small size of nanoparticles. They are not visible using a standard optical microscope. When the cellulose is broken down into nanoparticles, it is about one-thousandth the width of a human hair. "It creates a material that is better than steel and is comparable to Kevlar," says Österberg. Currently, the process used to break up cellulose into nanoparticles is still expensive, which is why so much work is being done to bring the price down. At the same time, research is being carried out to see what can be made from nanocellulose, SCA continues. The prospects are extremely promising, both with respect to improving existing products and new innovations. For example, paper and packaging can be made stronger and more translucent using nanocellulose. It can also be used in composite materials, which involves combining two different materials to strengthen each other. The result is a material that is both light and durable, and can replace today’s plastic materials, which have become a major environmental burden. "A fantastic benefit of wood-based materials is that they are derived from nature and are renewable," says Eriksson, group manager at the SCA R&D Center.

##SHARELINKS##

|

|

"With the introduction of new technology to the market, we feel it sets the TC-12 apart in the tree chipper market," said Al Goehring of DuraTech Industries. The TC-12 features a spring-loaded feed wheel with adjustable down pressure, an optional height sensor that automatically adjusts the feed roller to material size, and an optional hydraulic gathering winch. The hydraulic two-drum system feeds the heavy duty chipper disc. Debris is discharged through the chute that rotates 360 degrees. The manual chip deflector allows for complete control of the discharged material. The TC-12 has multiple safety features including the hopper safety light bars with easy and instant shutdown of the feed wheels. It also has two E-stop switches, a disc hood closed proximity switch, and a breakaway brake switch to ensure the safety of the operator. "Safety is a major concern when operating chippers," said Al Goehring of DuraTech. "The precautions installed on the TC-12 allow the users to operate safely and benefit from full use of all the features." The heavy duty chipper is compact, measuring 79 in. wide and 208 in. long. It is available with a pintle or ball hitch for towing to job sites. More information is available on the company’s website. ##SHARELINKS##

|

|

"Pressure sensitive converters want stunning label graphics for their brand owner customers, delivered on a North American sourced label paper that meets their stringent quality standards and maximizes operational efficiencies. OptiLabel HB delivers on all of these key objectives." says David Diekelman, NewPage executive director of sales and business development for specialty papers. The product is manufactured on No. 3 paper machine, one of three machines at NewPage’s Escanaba, Mich., mill. The 262-in. trim width No. 3 machine was recently converted to manufacture release liner and label facestock papers for the pressure sensitive industry. ##SHARELINKS##

|

|

Geämi, Morrisville, N.C., has introduced an eco-friendly alternative to plastic bubble wrap. The two-part paper packaging system used to protect fragile objects from shipping damage is made with perforated "cardboard-like" brown kraft paper certified by the Sustainable Forestry Initiative (SFI). The kraft paper is die-cut in a process with thousands of horizontal slits. When expanded, the paper becomes a 3-dimensional, web-like honeycomb of angled cells. A layer of tissue then gets laid on top, providing additional cushioning. Geämi’s tissue paper is 100% post industrial recycled content. The brown kraft paper is available in either virgin fiber or a 60/40 blend (post industrial/virgin fibers). ##SHARELINKS##

|

|

RockTenn, Norcross, Ga., USA, this week announced a $50 per ton price increase on its Millennium grades of 100% high strength recycled paperboard. Price increases are effective with shipments beginning September 13. With annual net sales of approximately $3 billion and 10,000 employees. RockTenn operates paperboard, containerboard, and consumer and corrugated packaging facilities in the U.S., Canada, Mexico, Chile, and Argentina. ##SHARELINKS##

|

|

Sappi, reports that it will increase prices of woodfree coated fine paper sheets and reels by a minimum of 7% and woodfree uncoated fine paper sheets and reels by a minimum 10%, beginning September 1. In making the announcement this week, Sappi noted that the continuous rise in input costs has kept the profitability for the industry at unacceptably low levels. Energy, wood and transportation costs, which form major parts of the industry’s cost base, have recently started to increase sharply, following the unprecedented rise in pulp prices, it added. Woodfree coated prices have not yet recovered to sustainable levels and European prices are still too low despite industry operating rates reaching maximum levels following capacity reductions over the past two years, Sappi continues "We expect operating rates to continue to remain strong for the foreseeable future, but further increasing input costs have kept margins at unsustainably low levels ##SHARELINKS##

|

|

Rayonier, Jacksonville, Fla., USA, reports that Lynn Wilson has joined the company as VP, forest resources. She is a member of the senior management team and is responsible for all aspects of managing the company’s 2.3 million acres of timberlands in the U.S. including operations management, research and silviculture, business and value-added product development, and strategy development. Wilson brings 24 years of forest and management experience to Rayonier. Prior to joining the company, she served as VP, operations support with Plum Creek, a position she reached after holding a variety of responsibilities, including company logging superintendent, senior resource manager, and GM. Wilson began her career in 1986 with Scott Paper. ##SHARELINKS##

|

|

Mark your calendars for TAPPI PRESS’ Back to School Sale, August 16-22. For seven days only, TAPPI PRESS is offering special pricing on a number of titles related to the industry. Here’s a sampling:

Save from August 16-22 when you order any title on the Back to School Sale list. Discount applies to members and non-members. Check the TAPPI home page starting Monday, August 16, for more details and pricing. ##SHARELINKS##

|

|

TAPPI is now offering Pira International’s new report, Ten-Year Forecasts of Disruptive Technologies in Paper and Board to 2020. The report is at the printers and has attractive pre-publication pricing before 31 August 2010. Author Dr. Martin Hubbe, a long time TAPPI member, used 34 years of research experience and a panel of leading paper and technology experts to create a ranked listing of the top 25 technologies in our business today. Report readers gain useful insights from 75 tables and figures as well as a technology forecast according to pulp and paper grades. For more information on this Pira market report from TAPPI, visit online. If you aren’t now a TAPPI member, join now and become instantly qualified to receive the member benefit of the discount on Pira publications! Pira offerings apply 80 years of experience in the paper, packaging and printing industries. Also note that this report is just one of many market reports that TAPPI offers. ##SHARELINKS##

|

|

David A. Carlson with Fibre Box Association in

With more than 46 years of experience in the pulp and paper industry Carlson is a graduate of Northwestern University with both a bachelor of science in engineering and masters of business administration, Carlson is technical advisor to Fibre Box Association. His service to TAPPI over the years has included TAPPI Board of Directors, TAPPI Fellow, division technical editor of TAPPI Journal and Corrugating International, and chair of eight committees including Corrugated Containers Division, Awards Committee, Technical Session Developer, Technical Roundtable, Division Technical Program and Technical Seminar. He was the 2006 recipient of TAPPI Herman L. Joachim Distinguished Service Award, one of the association’s highest honors. He has served on 21 committees within TAPPI. Carlson has dozens of publications and presentations to his credit and he regularly presents workshops and seminars for TAPPI and other professional organizations. Carlson will receive his award at the TAPPI/AICC Corrugated Week in Baltimore, Md., October 4-8, 2010. ##SHARELINKS##

|

|

By attending the Extrusion Coating Course August 24-26 in Charleston, SC, USA you will enhance your troubleshooting skills and gain a better understanding of materials and the extrusion processes to enable you to improve your existing extrusion coating operation. Registration also includes a half-day Paper and Board Manufacture and Properties Workshop led by Chuck Klass. This workshop will cover an overview and terminology of paper & board grades that are PE extruded; properties of paper and paperboard grades used for extrusion coating; paper and board manufacturing variables that impact extrusion coating; and trends and new developments. View the complete course schedule. Learn more at www.tappi.org/10extru. ##SHARELINKS##

|

|

This November 10-11, join your colleagues in Chicago, Ill. USA for Specialty Papers 2010 -- the only conference devoted exclusively to the latest developments in the specialty papers sector. The technical program includes 18 presentations from a cross-section of industry experts from organizations like Suntech Resources LLC, Hewlett Packard, Kimberly Clark, FPInnovations and Western Michigan University. You will find two days of in-depth coverage of global market trends; insights into how to improve the manufacturing process, reduce costs and increase competitiveness; the latest technology developments and the forecast for sustainability and LCA. The conference includes two round-table lunches covering the industry's hot-button topics (as determined by attendees!) where attendees can share and learn from successes and setbacks. Register before August 27, 2010 to take advantage of the 'Super Early Bird' savings! ##SHARELINKS##

|

|

The technical program is now available for the TAPPI 11th Advanced Coating Fundamentals Symposium. The symposium will be held October 11-13, 2010 at one of the world's leading paper research centers, PTS (Papiertechnische Stiftung) in Munich, Germany. Held every two years, this highly regarded symposium provides a forum for research and development professionals, chemists and technical service managers involved in paper coatings to discuss the latest technical developments. The technical program at this year’s symposium includes 30 peer-reviewed papers covering a wide range of topics like advanced printing fundamentals, sustainable barrier coatings, liquid interactions, optical control and advanced understanding of curtain coater application. The Symposium will also include a peer-reviewed poster session. Abstracts for the poster session are being accepted through August 27, 2010. View the details. ##SHARELINKS##

|

|

Leading researchers, industry experts, and other stakeholders will be meeting at the Dipoli Congress Centre in Espoo, Finland 27-29 September 2010 for the International Conference on Nanotechnology for the Forest Products Industry. One of the highlights of this event is the Poster Sessions featuring more than 40 posters that will showcase the latest breakthrough concepts and research in nanotechnology. TAPPI, along with programming partner VTT, has created a technical program that contains more than 80 peer-reviewed papers and three keynote presentations. Learn more about the event by viewing the conference brochure. The early bird registration deadline for this conference is 31 August 2010. Register today for the best rates. ##SHARELINKS##

|

|

The 9th Research Forum on Recycling will continue its history of highlighting cutting-edge research results from around the world. Held every three years, this event will provide participants an extraordinary opportunity to hear the latest in recycling research, discuss and debate technical and operating issues, learn and network with experts and peers, and identify future research needs of the recycling community. One registration will gain you access to both the PEERS Conference and Research Forum on Recycling programs. Esteemed engineers, scientists and practitioners will lead sessions on all aspects of recycling technologies and operations for raw materials, ranging from newsprint to mixed office waste, during more than 35 cutting-edge presentations. ##SHARELINKS##

|

|

August 9-10 August 11-12 August 17-18 August 24-26 August 24-26 ##SHARELINKS##

|

For the month of June, Sappi, Brussels, Belgium, reports that it made a EUR 1 donation for every ton of paper delivered to clients. The funds raised went towards building an education for the children of Haiti through the "Stichting Naar School in Haiti," started by Dutch born Marijke Zaalberg in January 1999.

For the month of June, Sappi, Brussels, Belgium, reports that it made a EUR 1 donation for every ton of paper delivered to clients. The funds raised went towards building an education for the children of Haiti through the "Stichting Naar School in Haiti," started by Dutch born Marijke Zaalberg in January 1999.  Don Lewis, president of SCA Tissue North America (pictured to the right), said that the wind turbines stand as a symbol of SCA’s commitment to sustainability and its environmentally friendly products. "At SCA we’re all working together to reduce our environmental footprint across the globe," he pointed out. The company has set a target to reduce our carbon dioxide emissions globally by 20% from fossil fuels and purchased electricity and heat by 2020. SCA has also set a global goal to reduce our water consumption by 15% by the end of this year compared with 2005 levels."

Don Lewis, president of SCA Tissue North America (pictured to the right), said that the wind turbines stand as a symbol of SCA’s commitment to sustainability and its environmentally friendly products. "At SCA we’re all working together to reduce our environmental footprint across the globe," he pointed out. The company has set a target to reduce our carbon dioxide emissions globally by 20% from fossil fuels and purchased electricity and heat by 2020. SCA has also set a global goal to reduce our water consumption by 15% by the end of this year compared with 2005 levels."

Nano is currently the magic word in many fields of research, including the forest industry, SCA, Stockholm, Sweden, points out, adding that using nanocellulose, it is possible to create translucent paper and new super-strong materials. "Nanocellulose can offer us more possibilities than we can imagine," says Marie Eriksson and Folke Österberg at the SCA R&D Center in Sundsvall, Sweden. For example, new intelligent packaging is a key research area for the forest industry. Eriksson and Österberg hope that today’s method of packaging food in a plastic container will become a thing of the past and be replaced with packaging material from the forest.

Nano is currently the magic word in many fields of research, including the forest industry, SCA, Stockholm, Sweden, points out, adding that using nanocellulose, it is possible to create translucent paper and new super-strong materials. "Nanocellulose can offer us more possibilities than we can imagine," says Marie Eriksson and Folke Österberg at the SCA R&D Center in Sundsvall, Sweden. For example, new intelligent packaging is a key research area for the forest industry. Eriksson and Österberg hope that today’s method of packaging food in a plastic container will become a thing of the past and be replaced with packaging material from the forest.  DuraTech Industries, Jamestown, N.D., USA, this week introduced its TC-12, 12-in. tree chipper. DuraTech notes that it harnessed the grinding technology of its massive tub and horizontal grinders for use in the TC-12. With a 122 hp (91 kw) CAT C4.4 diesel engine and PT Tech clutch, the TC-12 can chip limbs and logs up to 12 in. in dia.

DuraTech Industries, Jamestown, N.D., USA, this week introduced its TC-12, 12-in. tree chipper. DuraTech notes that it harnessed the grinding technology of its massive tub and horizontal grinders for use in the TC-12. With a 122 hp (91 kw) CAT C4.4 diesel engine and PT Tech clutch, the TC-12 can chip limbs and logs up to 12 in. in dia.  NewPage Corp., Miamisburg, Ohio, USA, this week launched OptiLabel HB, a 54 lb high performance, general purpose label paper for North American and International pressure sensitive markets. NewPage notes that the development team for this new product set its sights on a label facestock that would maintain a premium appearance and consistently perform well in all aspects of production, from pressure sensitive laminating and label printing to die cutting and high speed label application.

NewPage Corp., Miamisburg, Ohio, USA, this week launched OptiLabel HB, a 54 lb high performance, general purpose label paper for North American and International pressure sensitive markets. NewPage notes that the development team for this new product set its sights on a label facestock that would maintain a premium appearance and consistently perform well in all aspects of production, from pressure sensitive laminating and label printing to die cutting and high speed label application.