Over the Wire

TAPPI

|

As tentatively announced in Over the Wire last week, the Forest Products Association of Canada (FPAC), Montréal, Qué,, Canada, with support from the Government of Canada, has now launched the Greenest Workforce, a resource tool that provides information on the dynamic direction of the industry and career opportunities available across Canada.

The forest products industry is also launching a competition to give eight promising students across Canada a paid Green Dream Internship that includes a four month paid summer placement at a forest products company, an iPad Mini, and a chance to win $5,000. "The forest products sector is now a future oriented business that is brimming with opportunity. It is now hiring and offering solid careers for those who care about their future, the environment, and their quality of life," said David Lindsay, president and CEO of FPAC, speaking at PAPTAC's Annual Paper Week event held in Montreal last week. Under Vision2020, FPAC has a set the goal of recruiting at least 60,000 or more workers by 2020 to meet the growing demand for such professions as millwrights, electricians, engineers, sales staff, truck drivers, foresters, chemists, and many more. "Our government's top priorities are job creation, economic growth, and long-term prosperity, so it is imperative that we match the skills of Canadians, especially younger workers, with the needs of the employers," said the Honorable Diane Finley, minister of human resources and skills development. "Through our partnership with the forestry industry, we are helping young Canadians to receive the skills and training needed to address skills shortages in the forestry sector and prepare them for future careers." Lindsay added that "we invite Canadians to visit the Greenest Workforce website to see the exciting opportunities now available. We also want to encourage students to consider applying for the internships to receive job training, skills development, and real-world experience within our growing sector." The contest requires students to submit a short video explaining why they would be perfect for a Green Dream Internship. Applicants receiving the most votes for their video attempt will get on a short list for interviews for the paid summer positions. The contest and voting period is now underway and ends March 31. More information is also available on FPAC's Vision2020 website. ##SHARELINKS##

|

|

TAPPI's newest publication, Tissue360° magazine, and TAPPI tissue experts have organized a comprehensive technical forum for PaperCon 2013 in Atlanta, Ga., USA, April 28 – May 1. Covering all aspects of tissue making, the Tissue Forum includes eight information- and data-packed sessions beginning Monday afternoon and continuing through Wednesday morning of PaperCon. The program is open to all full PaperCon registrants.

The Forum's eight sessions focus on tissue and hygiene product market trends and developments, the latest chemical, fiber, water, energy, control, and converting technologies, and explore new and emerging production technologies, with a special full-session look at yankee dryer issues and concerns. All material presented at Tissue Forum has been carefully selected and reviewed by TAPPI members with extensive tissue expertise, and most of the presentations include a written paper. In Session T1 beginning after the lunch break on Monday, Esko Uutela of RISI presents a data-rich analysis of the global tissue business and trends in North America. Complementing Uutela's presentation, Lindsay Gervais of Poyry International examines the fiber side of the tissue industry with a detailed report on developing cost, quality, and sustainability issues in the global tissue arena. Session T2 on Monday afternoon covers "Chemistry Solutions for Tissue Making" with a paper by Yuping Luo of Kemira Chemicals that examines the newest generation of wet strength resins for towel grades, and a close-up look at new approaches to evaluating and enhancing tissue softness by Timothy Patterson of Ashland Water technologies.. Session T3 on Tuesday morning examines "Fiber Usage and Supply for Tissue" from four different fiber type perspectives. Fernando Pescatori Silva of Eldorado Brasil updates attendees on eucalyptus fibers. Xuejun Zou of FPInnovations provides a current overview of softwood kraft pulps for tissue making, and Medwick Byrd of North Carolina State University looks at nonwood raw materials as a possible fiber source for tissue and specialty products. The recycled fiber sourcing side is covered by Dave Anderson of SCA. Leading up to lunch, Session T4 explores "Water and Energy Strategies for Tissue," with presentations by Thomas Jenn of Kimberly-Clark on conducting tissue machine audits to reduce fiber losses and improve pulp yield, maximizing post pressure roll solids with advanced press fabric structures by Roger Banks of AstenJohnson, and engineering effective void volume in tissue production by Glen Harvey of Xerium Technologies. Session T5 begins Tuesday afternoon with a focus on Premium Tissue Manufacturing Technologies. Dennis Jewitt of Metso Paper discusses advanced technologies for structured tissue products, Roberto Zane of Voith Paper explores premium tissue technologies that are enhancing the conventional tissue world, and tissue consultant Ed Graf reports on "air dried tissue" (ADT), an alternative to TAD and similar technologies. Session T6, completing Tuesday afternoon, provides a special review and analysis of the latest tissue control techniques. Doeung Choi of Ashland Water Technologies examines the use of process simulation in structured tissue and towel making, John Feola of Cristini North America presents a roundup of the latest process control tools to boost tissue machine performance, and Richard Falcoff of Alicona Corp. looks at 3D optical micro-measurement technology to quantify surface roughness with ISO traceable Sa values. Wrapping up the Forum on Wednesday morning, Session T7 (CEU's provided) focuses directly on "Yankee Reliability," beginning with a presentation by Clive Butler of PMT on diagnosing surface chatter. Sam Archer of Nalco then looks more closely at the impact of chatter on yankee surface reliability, Jerry Vandoros of Kadant covers yankee doctor considerations for improving safety and reliability, and John Yolton of SKF explores reliability best practices in the global tissue industry. Session T8 on "Converting Efficiencies" features presentations by John Cork of Ibis International on process air filtration for tissue converting and Karl Hilden of Papertech on solving tissue production and converting problems using event capturing camera systems. Completing the Forum's final session on Wednesday morning, Futura analyzes key factors for enhanced converting performance. More information about PaperCon 2013 and the Tissue360° Tissue Forum is available online, including online registration and the Tissue Forum program. ##SHARELINKS##

|

|

Orchids Paper Products Co., Pryor, Okla., USA, reports that its full-year 2012 net sales increased $3.0 million, or 3%, to $100.8 million, marking the first time the company has achieved more than $100 million in net sales. Total net sales in the fourth quarter of 2012 decreased 6% to $24.0 million, compared with $25.7 million in the same period in 2011.

The company's full year net sales of converted product were $90.5 million, a new 12-month record, which represented an increase of $8.6 million, or 10%, over 2011. Net sales of converted product in the fourth quarter of 2012 were $21.8 million, a decrease of $2.0 million, or 8%, over the prior year quarter. Full-year net income for 2012 was $9.3 million, an increase of $3.1 million, or 49%, compared with the $6.2 million in 2011. Fourth quarter 2012 net income was $2.2 million, a decrease of $561,000, or 21%, compared with $2.7 million of net income in the same period of 2011. Robert Snyder, president and CEO, said that "we are pleased to announce that our full year results include record sales levels for both converted product and total net sales, with converted product shipments of just over 7 million cases. This achievement continues our long-term trend of increasing sales. Shipments of the previously announced new business gains of approximately 1.1 million cases are proceeding within our expectations and we are off to a strong start in 2013. Additionally, we have secured additional new business that we expect will increase our annual run rate by the third quarter of 2013 to approximately 9 million cases." Snyder added that "our expected business growth in 2013 is the result of our continued success in penetrating the mid- and premium-tier market. These successes are a result of the diligent efforts of our team to further product development, implement our market strategy, and deliver best in class customer service. The market for business opportunities continues to be strong and we are optimistic about our future growth." ##SHARELINKS##

|

TAPPI's highest honor, the Gunnar Nicholson Gold Medal Award, will be presented to Vancouver, B.C., Canada, native Robert (Bob) Vyse at the 2013 PaperCon Conference Awards Dinner on Tuesday, April 30, 2013, in Atlanta, Ga., USA. Vyse began his career with MacMillan Bloedel in Vancouver and Powell River, B.C., followed by 10 years as VP and projects manager of Omni Continental Ltd. He then joined Devron Engineering (which subsequently became Measurex – Devron, Honeywell Measurex Devron, and Honeywell) where he was director of R&D and process control for more than 20 years before retiring in 2008. He was involved in the development and application of various control actuators and technology, in particular the combined application of steam and induction energy devices in advanced finishing technology. TAPPI's highest honor, the Gunnar Nicholson Gold Medal Award, will be presented to Vancouver, B.C., Canada, native Robert (Bob) Vyse at the 2013 PaperCon Conference Awards Dinner on Tuesday, April 30, 2013, in Atlanta, Ga., USA. Vyse began his career with MacMillan Bloedel in Vancouver and Powell River, B.C., followed by 10 years as VP and projects manager of Omni Continental Ltd. He then joined Devron Engineering (which subsequently became Measurex – Devron, Honeywell Measurex Devron, and Honeywell) where he was director of R&D and process control for more than 20 years before retiring in 2008. He was involved in the development and application of various control actuators and technology, in particular the combined application of steam and induction energy devices in advanced finishing technology.

An active member of TAPPI and PAPTAC conferences, he authored numerous papers on papermaking technology, in particular on CD weight, coat weight, moisture, and caliper control. He also lectured at UBC, TAPPI pressing and drying courses, and PAPTAC papermaking technology courses. In 2010, Vyse was honored with the TAPPI Process Control Division Award. His education includes BASc, MSc, and PhD degrees in Engineering Physics and Physics from the University of British Columbia, as well as a postdoctoral Fellowship at the Centre d'Etudes Nucleaires de Saclay in France "TAPPI is very pleased to announce that Bob Vyse will receive the 2013 Gunnar Nicholson Gold Medal award in recognition of his many significant contributions to the development and application of CD control technology," notes Larry N. Montague, president and CEO of TAPPI. "His work in advancing the science of cross machine control actuators and process technology has provided great benefit to the industry by improving paper quality and paper machine operations. This prestigious award recognizes the importance and the impact of this work." ##SHARELINKS##

|

|

This morning, February 14, the Forest Products Association of Canada (FPAC), Montréal, Qué., Canada, and its partners released their landmark Construction Value Pathways initiative, exploring new and unique opportunities for the Canadian forest products industry to gain a larger share of the $8 trillion a year global construction market. Jonathan Westeinde, Founder of Windmill Development Group and external project lead for the Construction Value Pathways initiative, unveiled trends and opportunities for the forest products industry during his breakfast address at the Montreal Wood Convention that began today at the Queen Elizabeth Hotel in Montréal.

The Construction Value Pathways project is groundbreaking market research that has identified key trends in the global construction industry and sets the forest products industry's sights on diversifying with more advanced products and pre-fabricated construction solutions of the highest environmental quality. FPAC and its partners undertook the initiative to examine how to diversify the lumber industry beyond its traditional markets and suite of products. Canada's forest products industry is a $57 billion dollar a year industry that represents 11% of Canada's manufacturing GDP. The industry is one of Canada's largest employers, operating in hundreds of Canadian communities and providing more than 230,000 direct jobs across the country. ##SHARELINKS##

|

|

Two Sides U.S., Inc., Chicago, Ill, is conducting a survey to gather opinions on paper bills versus e-bills. This important survey will take only five minutes to complete using the online form. Opinions are being sought from people both inside and especially outside of the print, paper, and mail value chain. Results will be published by Two Sides and also will be summarized in a near-future issue of Over the Wire.

As Two Sides explains, it is becoming common practice for companies to encourage consumers to switch to electronic billing services instead of paper bills. Sometimes this is presented as being better for the environment. "We would greatly appreciate a few minutes of your time to get your opinions about the environmental messages used to promote electronic billing," Two Sides emphasizes. Two Sides is an independent, non-profit organization created to provide members of the graphic communications supply chain a forum to promote the responsible production and use of print and paper, improve sustainability standards and practices, share experiences, and maximize customer confidence in our products. To participate in this survey, please use the easily completed online form. ##SHARELINKS##

|

The OpEx Maintenance and Reliability Workshop at TAPPI PaperCon 2013 in Atlanta, Ga., USA, on April 30, will be the third annual OpEx event in a row, and the fourth counting the extra edition at TAPPI's 2012 PEERS Conference in New Orleans last October. This year's OpEx in Atlanta examines the most successful paths today's P&P mills are taking to improve asset reliability. A special highlight for 2013 is a joint session with the Recycled Paper Trade Association (RPTA) that explores Operator Driven Reliability (ODR) from an up-close, mill case-study perspective. The OpEx Maintenance and Reliability Workshop at TAPPI PaperCon 2013 in Atlanta, Ga., USA, on April 30, will be the third annual OpEx event in a row, and the fourth counting the extra edition at TAPPI's 2012 PEERS Conference in New Orleans last October. This year's OpEx in Atlanta examines the most successful paths today's P&P mills are taking to improve asset reliability. A special highlight for 2013 is a joint session with the Recycled Paper Trade Association (RPTA) that explores Operator Driven Reliability (ODR) from an up-close, mill case-study perspective.

In the joint session with RPTA, Christer Idhammar with IDCON examines what has been tried with ODR, who's succeeded, what's failed, and why—all based on mill case study results. Tony Kenneson-Adams of RockTenn then looks in-depth at how his Solvay recycled containerboard mill in Syracuse, N.Y., set up its ODR program and the pitfalls they experienced along the way. Rounding out the joint OpEx/RPTA session, Jim Davis of Performance Consultants Associates illustrates how to effectively support ODR programs by building "The Perfect Maintenance Storeroom." The keynote speaker for OpEx 2013 is John Yolton with SKF, a highly respected paper industry reliability expert who will explore "The Continuing Journey to Asset Reliability Improvement." As Yolton notes, "with the NAM pulp and paper market contracting, only the most reliable equipment can provide a competitive advantage. Data demonstrates that there is clearly a return on investment for those ‘best' within the pool of competitors." Yolton's presentation will identify and discuss primary issues associated with the top 3%, e.g., the "best" and the "rest." The opening keynote session also includes presentations by Bill Wick of American Industrial Metrology on "A Holistic Approach to Paper Machine Alignment" and Dave Cutnaw of SKF on "Maintenance and Asset Reliability Strategies—Developing a Foundation for Success." The afternoon OpEx sessions focus on work force structuring and education. In addition to Michael Von Grumbkow of Voith Paper, who will dissect asset management from an OEM perspective, a team from GPAllied will examine new and proven approaches in use by today's pulp and paper mills. David Neikirk will outline how to best implement asset management strategies. Shon Isenhour will present a compendium of best M&R education practices, and Chris Davis and Bobby Allen discuss structuring and managing the Natural Work Team. Also in the afternoon sessions, Dave Mulcahey of SKF will discuss "Sealing Solutions for the Pulp and Paper Industry." More information about PaperCon 2013 and the OpEx Maintenance and Reliability Workshop, including registration procedures, is available online. Also available online is the 2013 OpEx Workshop program. ##SHARELINKS##

|

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013, in Atlanta, Ga., USA, and co-located with 2013 PaperCon and the Tissue Forum. Both the Tissue Forum and Tissue Properties & Manufacturing Course are being sponsored by TAPPI's Tissue360° magazine.

This is a great opportunity to get the most out of your conference experience. The Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties, and the effect of manufacturing. This course precedes the Tissue 360° Forum at PaperCon, and is an excellent educational compliment to these technical sessions. The course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters, and marketers with 0-5 years of experience in tissue manufacturing. More information about the Tissue Properties & Manufacturing Course is available online. ##SHARELINKS##

|

|

TAPPI has a set of Abstract Bulletins published by the Institute of Paper Science and Technology, but the bulletins and indexes for 1982 and 1983 are missing. If anyone has the 1982 and/or 1983 bulletins and indexes, bound together for each year or individually as separate publications, that they would like to donate to the TAPPI library, please contact David Bell at TAPPI. Office: 770 209-7209. Mobile: 678-480-9975. The Association would be most appreciative. ##SHARELINKS##

|

|

Below is the latest listing of job openings in the TAPPI Career Center. The current listing includes job openings for a variety of positions including application engineer, sales manager, electrical engineer, maintenance engineer/manager, mill manager, lab director, R&D manager/technical leader, executive director of a pulp and paper foundation, account sales/service reps, and process improvement manager. Current, specific job openings at companies and locations in the TAPPI Career Center include:

More information about these jobs is available online. ##SHARELINKS##

|

|

Demand for imported softwood logs in China increased in the second half of 2012 after declining during the first six months of the year. Total imports in the second half of 2012 were up 9%, but the increase was not equally distributed between supplying countries. Shipments from New Zealand and the U.S. were up 29% and 20%, respectively, while Russian exports to China fell 9% in the second half of last year compared with the first half, reports the Wood Resource Quarterly (WRQ), Seattle, Wash., USA.

Log imports for the full year were down 15% from 2011, which was the first year-over-year decline since 2008. From 2008 to 2011, China's imports increased by as much as 70% to a record 30 million cubic meters in 2011. Despite the decline in 2012, the total import volume was still the second highest on record. And for the month of December, there have never been more logs unloaded in Chinese ports than in December 2012. The most dramatic shift in log supply sources for China over the past few years has been the diminished exports from Russia and the sharp increase in log volumes entering from New Zealand. Just five years ago, China imported as much as 21 million cubic meters of softwood logs from Russia and only 1.2 million cubic meters from New Zealand. In the second half of 2012, the two countries shipped about 4.8 million cubic meters each. The average import value of New Zealand Radiata pine in the fourth quarter of 2012 was up a few dollars from the previous quarter, reaching the highest level seen since the third quarter of 2011, while the average value for most other species remained unchanged in the last quarter of 2012. Domestic log prices in China on the other hand, continued their upward trend with Chinese fir log prices being up 13% from the fourth quarter of 2011 to the fourth quarter of 2012 to reach an all-time high, according to the WRQ. Prices for other commonly used species such as Mongolian pine, larch, poplar, and birch were also at record high levels during the fourth quarter of 2012. More information is available online. ##SHARELINKS##

|

|

Global market pulp NBSK (northern bleached softwood kraft) prices last month rose ˜$20-$25 per metric ton m/m, to $893 per metric ton, reports Mark Wilde of Deutsche Bank. Currently, prices are ˜$55-$60 per metric ton below year-ago levels. Overall shipments are up 3.0% y/y YTD, with much of that growth driven by strength in softwood (+4.1% y/y), Wilde notes.

Among the key regions, shipments to China are up 13.8% YTD. North America (-0.2% YTD) and Western Europe (-1.3% YTD) were both sluggish, Wilde says. The YTD operating rate for market pulp is at 92% (2011 = 90%), he adds. Current softwood inventories remain well below average at 25 days of supply. Hardwood is on the higher side of its historical average at 37 days of supply. ##SHARELINKS##

|

|

Arctic Paper S.A., Poland, has increased its share in Rottneros, Sweden, to 51.6%. Arctic Paper, according to a report in EUWID Pulp and Paper this week, communicated on February 7 that it had been able to acquire not only the shares of Skagen Vekst Verdipapirfondet, who had previously publicly declined the offer, but another 4.3% in Rottneros.cThe 4.3% was acquired outside of the offer. Arctic Paper said that it may continue to acquire shares in Rottneros outside of the offer, provided that such potential acquisitions from time to time are deemed favorable.

Now that Arctic Paper owns a majority share in Rottneros, the company is once again hopeful that it will be able to acquire more than 90% in the pulp manufacturer and combine the two entities, EUWID noted. The acceptance period has once again been extended to February 25. ##SHARELINKS##

|

|

Cascades, Kingsey Falls, Que., Canada, has named Xerium Technologies, Raleigh, N.C., winner of the fourth edition of its Sustainable Supplier Award, a contest that recognizes best business practices in sustainable development among its suppliers. Created by the company's Corporate Procurement Department, the award enables Cascades to publicly acknowledge the efforts of its suppliers that have had positive repercussions on its products, processes, or manufacturing methods. The projects undertaken were also assessed on their environmental, societal, and economic impacts.

Xerium Technologies, with its Weavexx and Stowe divisions, has been working in the pulp and paper industry since the mid-1800s. The company provides forming fabrics, press felts, dryer felts, roll covers, and spreader rolls. Its long-standing business partnership with Cascades has led Xerium to integrate state-of-the-art rolls and fabrics in many Cascades Tissue Group plants in North America (Candiac, Eau Claire, Kingsey Falls, Mechanics, Memphis, Ransom, Rockingham, Scarborough, Whitby). Integrated projects on 14 machines have helped increase efficiency of operations. This optimization has generated significant savings in costs as well as a reduction in the consumption of water and energy in the targeted plants. Harold Bevis, president and CEO of Xerium, said that "I see this prize as one of the best incentives for encouraging suppliers like us to engage in a sustainable development approach with its clients. For the coming years, Xerium intends to continue developing paper machine clothing and rolls technology for the purpose of improving the performance of its clients." Cascades notes that the Sustainable Supplier Award is a prime example of the importance it attaches to good relations. According to Alain Lemaire, president and CEO of Cascades, "if year after year we succeed in distinguishing ourselves and in bringing to market top quality products, it is partly thanks to our suppliers who bring us concrete solutions and that help us improve ourselves." The prize was awarded during the annual meeting of Cascades' plant managers in North America, in front of more than 100 people. It was deemed the most appropriate time by Cascades because it made it possible to highlight the accomplishments of some plants as well as make known the supplier that is being honored and its expertise in other units of the company. In the photo below are (l-r): Alain Lemaire, Cascades' president and CEO; David Pretty, Xerium's president North America and PMC Europe; Harold Bevis, Xerium's president and CEO; John Lamont, Xerium's VP Sales; Stephane Dube, Cascades' corporate procurement manager; and Mario Plourde, Cascades' COO.

##SHARELINKS##

|

|

This past week China initiated anti-dumping probes into cellulose pulp (dissolving pulp) imported from the U.S., Canada, and Brazil, according to an online report by Xinhuanet, which is sponsored by the China-based Xinhua News Agency.

The Chinese Ministry of Commerce (MOC) reportedly will examine whether and to what extent such imports hurt the Chinese dissolving pulp industry and make decisions based on China's anti-dumping laws, the ministry said in a statement posted on its website. The probes are expected to end within a year and can be extended for another six months under special circumstances. Dissolving, or cellulose, pulp is used as a raw material in the production of viscose and acetate fiber used to manufacture rayon textiles, films, and other materials. ##SHARELINKS##

|

|

Clearwater Paper Corp., Spokane, Wash., USA, has published its initial Corporate Social Responsibility (CSR) report. Clearwater notes that the CSR will serve as a benchmark against which to measure its progress on several key metrics. The report pledges resource investments in strategies and projects that reduce the company's environmental footprint associated with water, air, greenhouse gas emissions, waste, and energy.

"Sustainability has been part of our DNA for more than a century," said Linda Massman, president and CEO of Clearwater Paper. "This report formalizes our long-demonstrated commitment to doing business in a way that is good for people, good for the environment, and good for the future of the company." Specifically, Clearwater Paper's CSR outlines the company's goals to reduce water consumption by 20%, energy consumption by 15%, manufacturing solid waste to landfills by 20%, and greenhouse gas emissions by 15% by 2017. "Developing and issuing our first CSR gave us the opportunity to share information about our innovative historical projects as well as define future sustainability expectations," said Marv Lewallen, VP of environmental, energy, and sustainability. "Sharing future CSR's will be an exciting and constructive method in which to show progress against our goals and demonstrate our successes in all aspects of our sustainability efforts." Most of Clearwater Paper's carbon emissions are related to consumption of purchased energy used to produce paper products at 15 manufacturing locations in the U.S. and Canada. The company produces consumer tissue, away-from-home tissue, parent roll tissue, machine glazed tissue, bleached paperboard, and pulp. It is a supplier of private label tissue to major retailers and wholesale distributors. This includes grocery, drug, mass merchants, and discount stores. The full CSR report http://www.clearwaterpaper.com is available online. ##SHARELINKS##

|

Coldwater Group Inc., Atlanta, Ga., USA, this week announced the addition of a doctor blade manufacturing area to its Atlanta facility, and the introduction of Kirwin doctor blades to the North American market. Coldwater acquired R&E Kirwin Ltd., doctor blade manufacturers and engineers located in Chesterfield, England, in May 2012. The Kirwin business was moved to Coldwater's Swedish facility near Karlstad later in the year. Kirwin has been a prominent supplier of doctor blades in Europe, Africa, and Asia for more than 30 years. Coldwater Group Inc., Atlanta, Ga., USA, this week announced the addition of a doctor blade manufacturing area to its Atlanta facility, and the introduction of Kirwin doctor blades to the North American market. Coldwater acquired R&E Kirwin Ltd., doctor blade manufacturers and engineers located in Chesterfield, England, in May 2012. The Kirwin business was moved to Coldwater's Swedish facility near Karlstad later in the year. Kirwin has been a prominent supplier of doctor blades in Europe, Africa, and Asia for more than 30 years.

Coldwater in Atlanta and Karlstad can now manufacture Kirwin doctor blades from carbon fiber, epoxy glass, cotton phenolic, polyethylene, bronze, stainless steel, and carbon steel for any style of doctor blade or creping blade holder. Both facilities also stock all of the necessary clips, rivets, tubes, and springs for quick deliveries. Coldwater also announced that Bill Frawley has joined its staff as U.S. product manager for the Kirwin line. Frawley has many years of experience in doctor blade applications. More information on all Coldwater products and services is available online. ##SHARELINKS##

|

|

Holmen Paper, Stockholm, Sweden, this week reported that it is investing SEK 200 million ($31.2 million) in restructuring the energy supply at its Hallsta Paper Mill in Sweden. This is the single largest investment in the mill since the PM 11 paper machine was built in 2002. The planned measures strengthen the mill's competitiveness and form part of the transition to a two-machine mill, and will be completed by the summer of 2014.

"We're providing Hallsta Paper Mill with completely new opportunities for the future," said Henrik Sjölund, head of Holmen Paper. "By improving heat recovery from paper machines and pulp manufacture, we'll be able to run the mill in a more energy-efficient manner." The restructuring also involves closing the two old solid fuel boilers, which will be possible when, as previously announced, the PM 3 paper machine is closed during the second half of this year. The investment package also includes more modern and efficient monitoring of the process. "These investments will make Hallsta Paper Mill a modern mill with two paper machines that occupy leading positions in their niches—magazine and book paper. The mill will also be a significant supplier of biofuel, as it will have a surplus of bark that was previously burned in the solid fuel boilers," Sjölund noted. ##SHARELINKS##

|

|

Orchids Paper Products Co., Pryor, Okla., USA, reports that its full-year 2012 net sales increased $3.0 million, or 3%, to $100.8 million, marking the first time the company has achieved more than $100 million in net sales. Total net sales in the fourth quarter of 2012 decreased 6% to $24.0 million, compared with $25.7 million in the same period in 2011.

The company's full year net sales of converted product were $90.5 million, a new 12-month record, which represented an increase of $8.6 million, or 10%, over 2011. Net sales of converted product in the fourth quarter of 2012 were $21.8 million, a decrease of $2.0 million, or 8%, over the prior year quarter. Full-year net income for 2012 was $9.3 million, an increase of $3.1 million, or 49%, compared with the $6.2 million in 2011. Fourth quarter 2012 net income was $2.2 million, a decrease of $561,000, or 21%, compared with $2.7 million of net income in the same period of 2011. Robert Snyder, president and CEO, said that "we are pleased to announce that our full year results include record sales levels for both converted product and total net sales, with converted product shipments of just over 7 million cases. This achievement continues our long-term trend of increasing sales. Shipments of the previously announced new business gains of approximately 1.1 million cases are proceeding within our expectations and we are off to a strong start in 2013. Additionally, we have secured additional new business that we expect will increase our annual run rate by the third quarter of 2013 to approximately 9 million cases." Snyder added that "our expected business growth in 2013 is the result of our continued success in penetrating the mid- and premium-tier market. These successes are a result of the diligent efforts of our team to further product development, implement our market strategy, and deliver best in class customer service. The market for business opportunities continues to be strong and we are optimistic about our future growth." ##SHARELINKS##

|

|

ST Tissue. Oconto Falls, Wis., USA, has started up its converted recycled tissue machine at the former International Paper uncoated freesheet paper mill in Franklin, Va. (photo). With a capacity of 70,000 tpy, the machine will produce parent reels for a variety of semi-crepe tissue grades from napkin to towels, and bleached to kraft products, according to a report this past week by UBM's Tissue World E-News. The mill has some 80 employees.

The company, owned and operated by Tak Investments, Gaithersburg, Md., at Franklin is said to have North America's largest tissue machine, with a usable web width of 310 in. The width of the machine will allow the company to offer a variety of trim sizes and its onsite recycled fiber plant will allow it the flexibility to transform waste paper into different grades of recycled pulp, Tissue World E-News reported. Tac Investments purchased the Oconto Falls mill is April 2007, and following several equipment upgrades and revitalization projects, today is producing approximately 160 tpd of deink tissue there, with nearly 100 employees. ##SHARELINKS##

|

|

Starboard Value LP, New York, N.Y., USA, the largest shareholder of Wausau Paper Corp. with approximately 14.8% of its outstanding common stock, this week said that it has filed preliminary proxy materials with the SEC regarding the election of directors to the Wausau board at its 2013 annual meeting.

For the past couple of years, Starboard says it has urged Wausau to exit its paper business, including both its Print & Color business and its Technical Paper business, and focus on its highly profitable Tissue business. Last year Wausau decided to sell only the Print & Color portion of its Paper segment, as well as its non-core timberland assets. Recently, it reportedly committed to exploring the possible sale of its Technical Paper Business. Starboard has maintained its view that Wausau needs to either sell its "non-core, money-losing" Technical Paper business, focus on its Tissue business, and reduce redundant overhead costs, or sell the entire company. Starboard's three candidates for the Wausau board are John S. Kvocka, George Patrick Murphy, and Jeffrey C. Smith. Kvocka is a former VP and CFO of Finch Paper LLC, a producer of uncoated printing and writing papers, and former VP of business development for SCA Tissue North America. He is currently president and CEO of JSK Assoc., an entrepreneurial and consulting entity. Kvocka is a former senior advisor and director of Apex Resource Technologies Inc., a medical device manufacturing company, and senior advisor and director of Garnet River LLC, an IT services and business consulting firm. Murphy is the former VP and business leader of the Away-from-Home Division of Kimberly-Clark Corp., and former CEO of Technical Concepts LLC. He is currently a senior operating partner of Hudson Ferry Capital, a private equity firm, and a member of the executive team of advisors of Mason Wells, a private equity company. Murphy served on the board of directors, including in the role of executive chairman, of Atlas Paper Mills LLC, a tissue producer located in Miami, Fla. Smith is co-Founder and CEO of Starboard Value. He has extensive public company board experience, and currently serves on the board of Regis Corp. Previously he was chairman of Phoenix Technologies and a director of Zoran Corp., Actel Corp., S1 Corp., Kensey Nash Corp., and SurModics Inc. He also served as a member of the management committee for Register.com. ##SHARELINKS##

|

|

Italian tissue machine supplier Toscotec S.p.a. reports that it has achieved a "striking result," starting up 10 of its tissue machines in little more than three months. From Oct. 15, 2012, to Jan. 31, 2013, the company completed tight-schedule tissue machine startups on three different continents—Africa, Europe, and Asia.

Among these projects are turnkey solution tissue plants equipped with AHEAD-1.5M and MODULO-PLUS in energy saving configuration with different scopes of supply, but all including engineering and overall services for international customers such as Vinda, Sipat S.A., C&S Paper, and MP Hygiene. Toscotec notes that, thanks to a worldwide structure that includes Toscotec Asia & Pacific in Shanghai and Toscotec North America in Green Bay, Wis., USA, it has made its service team available to companies installing all 10 of the recent tissue machines. These machines were supplied with a comprehensive package of services aimed at increasing efficiency and output, including training, maintenance, and process assistance. ##SHARELINKS##

|

MeadWestvaco Corp., Richmond, Va., USA, has launched its inaugural consumer satisfaction study, "Packaging Matters." The study explores the role of packaging in product satisfaction as consumers purchase, transport, use, and dispose of products across 10 different categories. The results suggest that packaging satisfaction can have a significant impact on purchase intent and repeat purchase, and that there is a low level of satisfaction overall, especially once consumers leave the store and rely on the structural or functional features of the package at home or on-the-go. MeadWestvaco Corp., Richmond, Va., USA, has launched its inaugural consumer satisfaction study, "Packaging Matters." The study explores the role of packaging in product satisfaction as consumers purchase, transport, use, and dispose of products across 10 different categories. The results suggest that packaging satisfaction can have a significant impact on purchase intent and repeat purchase, and that there is a low level of satisfaction overall, especially once consumers leave the store and rely on the structural or functional features of the package at home or on-the-go.

The study clearly shows that when it comes to purchase intent and product satisfaction, packaging does matter. A majority of consumers will sometimes buy a product off the shelf without prior knowledge of it (64%) and rarely use mobile devices to research a product while shopping (72%). While quality (85%) and price (67%) are the most important factors contributing to overall product satisfaction, consumers report little variance in importance between a product's brand (12%) and packaging (10%). Despite the importance of packaging, there is a clear opportunity for improvement. Fewer than 20% of U.S. consumers report they are "very satisfied" with product packaging, with the least amount of satisfaction from carry-out food containers and beauty care product packaging. "The research further proves that packaging is one of the most powerful tools in the marketing communications mix, but as it stands now, packaging does not delight consumers," said Brian Richard, director, Consumer and Customer Insights, MWV. "Brands should view the current gap in satisfaction as an opportunity to make improvements to their packaging by focusing on what matters most to consumers." The study identified "satisfaction gaps"—the importance of different packaging attributes compared with their perceived performance. Of the 15 packaging attributes studied, only a small percentage of consumers ranked shelf appeal, or the product's "attractiveness" and "distinctiveness," as "very important" features to their satisfaction (6% and 10%, respectively). However, this is where brands were performing best, with performance exceeding importance. While brands are generally pleasing consumers during the shopping experience, satisfaction drops dramatically when product packaging is relied upon for transport and storage and then when the product is used and reused. The largest satisfaction gaps across categories all relate to the structural features or functionality of the packaging. In terms of importance, consumers want packaging that protects from breaking or spilling (74%), maintains product integrity (72%), and gets the entire product out of the package (66%). "Packaging satisfaction decreases significantly after consumers leave the store, at all touch points along the product lifecycle, such as transporting, storing, and using the product. This is a huge missed opportunity for brands," said Steve Kazanjian, VP, Global Creative, MWV. "Structural features of the packaging should be viewed as the most critical area for brands to make improvements to drive consumer satisfaction. "Packaging that lives up to the brand promise of its marketing communications holds the most potential for repeat purchase. As more retail migrates online, consumers are interacting less with brick-and-mortar channels. A disappointed consumer can switch brands with one click, so the role of packaging is increasingly an important vehicle for brand owners to connect with their consumers at touch points throughout the product's lifecycle," Kazanjian added. Results of "Packaging Matters" reveal a significant variance across a variety of demographics and categories. For example:

"Packaging Matters: Packaging Satisfaction Study" was commissioned by MWV and studied the shopping habits and consumers satisfaction with packaging from store shelf to transport, storage, use, and disposal of 3,000 U.S. consumers. Full study results http://mwv.com/packagingmatters are available online. ##SHARELINKS##

|

|

The Newark Group, Cranford, N.J., USA, a producer and converter of 100% recycled paperboard in the U.S. and Canada, this week announced that it has completed a $186 million refinancing transaction. The company successfully raised debt financing consisting of an undrawn $50 million ABL Revolving Credit Facility, an $80 million 1st Lien Term Loan, and a $56 million 2nd Lien Term Loan.

"This is a significant enhancement for the Newark Group. It permits the company to invest in equipment, technology, and talent," said Frank Papa, Newark CEO and president. "The refinancing increases the countless capabilities in paperboard design and functionality that we can offer our customers and vendors." Newark CFO Gregg Kam noted that "the successful completion of the refinancing represents a vote of confidence in Newark's strategic vision and represents another step in the company's operational and financial transformation." ##SHARELINKS##

|

Voith, Germany, this week reported that it is now offering complete pulp drying machines, from headbox to the cross cutter and bale packing. A particularly new and unique feature of the company's pulp dryers is the vertical arrangement of the rolls in the dryer section. The patented innovation saves energy and leads to a much higher evaporation, according to Voith. Voith, Germany, this week reported that it is now offering complete pulp drying machines, from headbox to the cross cutter and bale packing. A particularly new and unique feature of the company's pulp dryers is the vertical arrangement of the rolls in the dryer section. The patented innovation saves energy and leads to a much higher evaporation, according to Voith.

Installed on a pilot machine in São Paulo, Brazil, the vertical dryer section is saving energy, space, and costs, Voith notes. The installed former, it says, ensures that the web enters the dryer section with a much higher dry content, adding that mechanical dewatering is less expensive than thermal dewatering. With the vertical section, steam consumption in the dryer section is reduced significantly compared with conventional sections, Voith says. Due to more efficient evaporation, the temperature of the web in the dryer section also has been reduced. Another benefit of the higher evaporation rate is the reduced size of the dryer and therefore of the building. High energy and cost savings are thus achieved. Brazilian pulp producer Lwarcel Celulose in Lençóis Paulista, Brazil, has found additional advantages with the vertical arrangement of the dryer section. Altogether, it reports, the vertical arrangement is substantially more space-saving. Also, Lwarcel installed the vertical dryer section directly after its existing conventional dryer section on a running drying machine, and reports that the vertical section has an extremely practical side-effect when there is a web break—the broke web doesn't build up between the rolls, but instead simply falls through the vertical arrangement. Cleaning takes only minutes rather than hours. Voith points out that the pilot machine in São Paulo illustrates the entire pulp drying process and offers customers the chance to conduct their own test runs. In the pulp drying arena, Voith has been installing NipcoFlex presses in pulp drying machines since 1998, but the company now is no longer providing just individual components, but rather the entire production line, it emphasizes. ##SHARELINKS##

|

|

FPInnovations and Natural Resources Canada's CanmetENERGY, Montréal, Qué., Canada, this week signed a memorandum of understanding formalizing the collaborative efforts of research teams from both organizations after years of informal cooperation. The primary objective of these efforts is to identify and commercialize novel products and technologies from bio-economy-based forest operations with a view to providing economic benefits and jobs to communities across Canada.

"Our Government is committed to fostering strong working relationships with partners such as FPInnovations," said the Honorable Joe Oliver, Canada's Minister of Natural Resources. "Today's announcement will lead to investment in forest sector innovation and market development and create opportunities that support jobs and economic growth in communities across Canada." "This agreement formalizes the long-standing relationship between FPInnovations and Natural Resources Canada and provides a strong framework for future cooperation", said Pierre Lapointe, CEO of FPInnovations. "Such agreements are the cornerstone that will enable Canada's forest sector to maximize the potential of the bio-economy and in doing so, help meet the targets outlined in the Forest Products Association of Canada's Agenda 2020, an ambitious plan that challenges us all to find innovative ways to further transform the sector." Researchers from both organizations will work together to exchange scientific and technical information and collaborate on joint projects to deliver innovative solutions in the areas of energy efficiency, process integration, energy cogeneration, biorefining, and the transformation of forestry biomass to bioenergy and high value bioproducts. This builds on the extensive degree of cooperation between FPInnovations and Natural Resources Canada's Canadian Forest Service. With more than 450 scientists, engineers, and technicians and 100-plus years of experience, CanmetENERGY is Canada's knowledge center for scientific expertise on clean energy technologies. CanmetENERGY supports Natural Resources Canada's priorities to promote the sustainable and economic development of the country's natural resources, while improving the quality of life of Canadians. It has world-class energy research centers of expertise in Devon, Alberta, Ottawa, Ontario, and Varennes, Qué. FPInnovations has a total staff of more than 525 people. Its R&D laboratories are located in Québec City, Ottawa, Montréal, Thunder Bay, Edmonton, and Vancouver, and it has technology transfer offices across Canada. ##SHARELINKS##

|

|

Kadant Inc., Westford, Mass., USA, reports that former U.S. Senator Scott Brown, (R-Mass.) has been appointed to its board of directors. This appointment was made following the retirement of Francis L. McKone, a member of Kadant's board of directors since 1998.

"During his time in public office, Senator Brown has gained a wealth of experience on local, state, national, and international issues and I am pleased that he has agreed to join our board of directors," said Jonathan W. Painter, president and CEO of Kadant. "His good judgment and pragmatic approach to solving problems will be a strong asset to Kadant as we continue to grow our business throughout the world. "Senator Brown's appointment to our board reflects our strong ties to Massachusetts. Kadant was founded in Massachusetts, our headquarters are in Westford, and one of our principal manufacturing facilities is in Auburn. Another former U.S. Senator from Massachusetts, Paul Tsongas, also served on our board of directors in the 1990s." Senator Brown said that "I am honored to have the opportunity to contribute to Kadant and learn more about the challenges of an international business. Kadant has been on the forefront of designing and manufacturing equipment to recycle and produce paper for decades. I look forward to sharing my knowledge and experiences and contributing to the future direction and growth of this global leader." ##SHARELINKS##

|

|

NewPage Holdings Inc., Miamisburg, Ohio, USA, this week announced that Patrick Buchenroth has accepted the position of controller and chief accounting officer for NewPage Holdings Inc. and NewPage Corp. His new position becomes effective February 25.

From May 2012 through last month (January), Buchenroth served as SVP of finance at ACCO Brands Corp., a global supplier of branded office products, following the company's acquisition of the Consumer and Office Products Division of MeadWestvaco Corp. Prior to the acquisition, from August 2005 through April 2012, he served as CFO for MeadWestvaco's Consumer and Office Products Division. In 2005, he was part of a team that orchestrated the sale of MeadWestvaco's Paper Division to form NewPage Corp. Prior to these roles Buchenroth was an audit partner for Deloitte & Touche, a public accounting firm. Buchenroth is a CPA and a graduate of Wright State University with a double major in Accountancy and Finance. He is also the treasurer of the United Way of the Greater Dayton, Ohio, area. NewPage is a producer of printing and specialty papers with $3.5 billion in net sales for 2011. The company owns paper mills in Kentucky, Maine, Maryland, Michigan, Minnesota, and Wisconsin, with a total annual production capacity of approximately 3.5 million tons of paper. ##SHARELINKS##

|

Staffan Jonsson has been appointed head of Group Technology at Holmen AB, Stockholm, Sweden. His new position becomes effective May 1. Holmen's head of Group Technology is a member of the senior management team and reports to the president/CEO. Staffan Jonsson has been appointed head of Group Technology at Holmen AB, Stockholm, Sweden. His new position becomes effective May 1. Holmen's head of Group Technology is a member of the senior management team and reports to the president/CEO.

Jonsson has worked as mill manager at Iggesunds Bruk for 12 years and has had previous senior positions both within and outside of Holmen Group. He will succeed Sven Wird, who is retiring after 18 years with the company. Holmen is a forest industry group that produces printing paper, paperboard, and sawn timber and runs forestry and energy production operations. The company's operations consist of three product-oriented business areas (Holmen Paper, Iggesund Paperboard, and Holmen Timber) and two raw-material-oriented business areas (Holmen Skog and Holmen Energi). ##SHARELINKS##

|

|

"TAPPI is very pleased to announce that Bob Vyse will receive the 2013 Gunnar Nicholson Gold Medal award in recognition of his many significant contributions to the development and application of cross-machine control technology," notes Larry N. Montague, president and CEO of TAPPI. "His work in advancing the science of CD control actuators and process technology has provided great benefit to the industry by improving paper quality and paper machine operations. This prestigious award recognizes the importance and the impact of this work." Vyse, a native of Vancouver, B.C., Canada, began his career with MacMillan Bloedel in Vancouver and Powell River, B.C., followed by 10 years as VP and projects manager of Omni Continental Ltd. He then joined Devron Engineering (which subsequently became Measurex – Devron, Honeywell Measurex Devron, and Honeywell) where he was director of R&D and process control for more than 20 years before retiring in 2008. He was involved in the development and application of various CD control actuators and technology, in particular the combined application of steam and induction energy devices in advanced finishing technology. An active member of TAPPI and PAPTAC conferences, Vyse authored numerous papers on papermaking technology, particularly on CD weight, coat weight, moisture, and caliper control. He also lectured at UBC, TAPPI pressing and drying courses, and PAPTAC papermaking technology courses. In 2010, Vyse was honored with the TAPPI Process Control Division Award. His education includes BASc, MSc, and PhD degrees in Engineering Physics and Physics from the University of British Columbia, as well as a postdoctoral Fellowship at Centre d'Etudes Nucleaires de Saclay in France. ##SHARELINKS##

|

|

Two special TAPPI webinars on February 21 and March 13 provide inside previews of PaperCon 2013 in Atlanta, Ga., USA, April 27 - May 1 Webinar No. 1 Innovation in Safety: The Leading Edge of Leading Indicators This discussion will focus on identifying, quantifying, and combining measurable parameters into a safety performance model that clearly defines both environmental risk and individual risk in a way that affords us necessary clues for an effective accident prevention program. Learn more. Webinar No. 2 ##SHARELINKS##

|

|

A special survey being conducted by Two Sides U.S. Inc., Chicago, Ill, is seeking opinions on paper bills versus e-bills. To participate in this very important survey, use the online survey form, which will take only about five minutes to complete. Opinions are being sought from people both inside and especially outside of the print, paper, and mail value chain. Results will be published by Two Sides and also will be summarized in a near-future issue of Over the Wire. As Two Sides explains, it is becoming common practice for companies to encourage consumers to switch to electronic billing services instead of paper bills. Sometimes this is presented as being better for the environment. "We would greatly appreciate a few minutes of your time to get your opinions about the environmental messages used to promote electronic billing," Two Sides emphasizes. Two Sides is an independent, non-profit organization created to provide members of the graphic communications supply chain a forum to promote the responsible production and use of print and paper, improve sustainability standards and practices, share experiences, and maximize customer confidence in our products. To participate in this survey, please use the easily completed online survey form. ##SHARELINKS##

|

|

Tissue360 Forum @ PaperCon 2013 Monday, April 29 - Wednesday, May 1 Atlanta, Ga., USA TAPPI's new Tissue publication, Tissue360o magazine, and TAPPI tissue experts have organized Tissue360 Forum, a comprehensive technical forum covering all aspects of tissuemaking. You will hear about the latest tissue technology, market trends, and pick-up some runnability/operational tips. The program is open to all full PaperCon registrants. Program Overview: Hygenic Products Market Overview Session Chairs: Ken Patrick, Tissue360o Chemistry Solutions for Tissue Making Session Chair: Gary Furman, Nalco Water and Energy Strategies for Tissue Session Chair: Tom Jenn, Kimberly-Clark Premium Tissue Manufacturing Technologies Session Chair: Soren Eriksson, Metso Tissue Controls and Measurement Session Chair: Rene Naranjo, AstenJohnson Yankee Reliability (CEUs provided) Session Chair: Al Coons, Clearwater Paper Converting Efficiencies Session Chair: Kevin Brennan, Ashland Water Technologies See the full Tissue360 Forum program. PaperCon will take place April 27 through May 1, 2013 in Atlanta, Ga., USA. Designed by industry professionals, PaperCon brings together CEOs, mill managers, superintendents, scientsits, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other such event provides such a comprehensive program, networking opportunites, and trade fair among such a distinguished group of industry leaders. Learn more abut PaperCon 2013. ##SHARELINKS##

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013 in Atlanta, Ga., co-located with PaperCon 2013 and the Tissue Forum. This is a great opportunity to get the most out of your conference experience. This Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties and the effect of manufacturing. The course precedes the Tissue Forum at PaperCon 2013 and is an excellent educational component to these technical sessions. This course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters and marketers with 0-5 years of experience in tissue manufacturing. Go to the course website to learn more. ##SHARELINKS##

|

The highly-regarded Executive Panel on Monday, April 29, will illuminate how industry leaders are thinking and driving innovation in their companies. See who's speaking. Designed by industry professionals, PaperCon (April 27 - May 1 in Atlanta, Ga., USA) will bring together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program with networking opportunities and trade fair among such a distinguished group of industry leaders. ##SHARELINKS##

|

Free TAPPI Webinar Tomorrow, Friday, February 15, 2013 12:00 - 1:00 PM EST What's Missing in Your Contractor Safety Management? In 60 short minutes, you will learn:

It is the only contractor orientation developed for and by the pulp and paper industry. Best of all, there is no cost to mills to participate in the program. TAPPISAFE will update or develop your site specific orientation once you enroll. Register now for the webinar. Webinar led by Larry N. Montague, president and CEO of TAPPI, Eric Fletty, VP of operations, TAPPI, and Tess Ventress, TAPPISAFE program director. ##SHARELINKS##

|

Gopal Goyal often notes that it is the connections he made through membership in TAPPI that really helped launch his career. "I kept telling people that I have gotten more out of TAPPI than TAPPI has gotten out of me." Having joined back in 1985 while a graduate student in pursuit of an advanced degree in the pulp and paper field, Gopal attended his first TAPPI pulping conference and was deeply impressed with the depth and breadth of knowledge he found under a single roof. "You could approach any of these experts and have a technical discussion, which helped me tremendously in focusing my graduate research," he said. That initial meeting led to nearly 30 years of active involvement, including an array of voluntary leadership positions. Since those early days, he has consistently found TAPPI to be a great venue for making connections with leading industry experts and establishing a global network of contacts. He also notes that the active volunteer role he pursues at TAPPI to this day helped him to develop and apply leadership and teambuilding skills at his job. Find out more by reading this month's Member Spotlight. Spotlight participants are recommended by fellow members and staff. If you wuld like to nominate a member just send their name (or names) to MemberSpotlight@tappi.org. We will forward a Spotlight Questionnaire to fill out and return. We look forward to seeing you in the Spotlight! ##SHARELINKS##

|

|

The highly regarded panel on Monday, April 29, will illuminate how industry leaders are thinking and driving innovation within their companies. See who's speaking. Designed by industry professionals, PaperCon will bring together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program, networking opportunities, and trade fair among such a distinguished group of industry leaders. ##SHARELINKS##

|

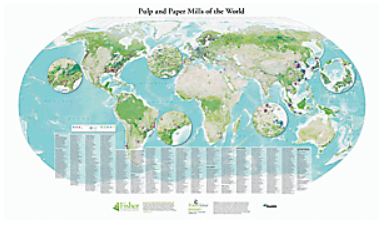

One of TAPPI's most exciting new products is the wall-sized, laminated 2013 Pulp & Paper "Mills of the World" Map. A winning combination of high quality print and paper stock along with brilliant colors makes this the perfect map to frame and hang in your office. The "Mills of the World" map features include:

Each map will be shipped in a protective tube, ready for display. ##SHARELINKS##

|

|

The Introduction to Traditional and Emerging Printing Technology Course will be co-located at the 2013 PaperCon Conference, April 27-29, 2013, in Atlanta, Ga., USA. This is an introductory course on printing methods and applications, designed for those who need to understand print quality, attend print trials, trouble shoot print problems or are generally new to printing operations. It will be taught by printing experts from TAPPI's Coating and Graphic Arts Division and is an excellent complement to the Coating Program at PaperCon. As an added bonus, the course will include a tour of Hewlett-Packard's new state-of-the art facility where production laser and inkjet presses will be demonstrated. Course attendees may also join the Coating and Graphic Arts Opening Session where printing visionary Frank Romano is giving the keynote address. Learn more and register online. ##SHARELINKS##

|

|

The Virginia-Carolina TAPPI Local Section is hosting its Winter Conference in Richmond, Va., USA, on Monday, February 25, with a program focus on "Boiler MACT and Bioenergy Enhancement, Policy, and Standards." Speakers include Dr. Justin Baker of RTI International, Roger Leimbach of Metso Automation, Phil Sparks of Save Environmental, and Dr. Med Byrd, Director of the Department of Forest Biomaterials, North Carolina State University. The conference will be held at the Hyatt Place Richmond Arboretum. Registration is open and table-top exhibit space can be purchased. The agenda and registration forms are both available online. ##SHARELINKS##

|

|

PaperCon Programs Now Available Customize your learning and networking experience at PaperCon to best fit your professional needs. Bring back ideas, innovation that will help you be more effective and efficient. Papermakers program will give you everything you need to know about paper machine performance evaluations, running mill trials, and product certification. Eight peer-reviewed Coating sessions focus on scientific developments and practical tips. Highlighs include opacity enhancement with Ti02 and advancements in barrier coating. PIMA Management sessions provide excellent insight for mill managers, production managers, and executives. This year's sessions will help you develop effective labor/management relationships and show you how to motivate today's employees. The Tissue360 Forum provides a comprehensive peer-reviewed technical program unlike any other. You will learn about fiber, water, and energy savings, the latest softness and strength additives, and forming concepts. The OpEx Reliability Workshop will help you improve reliability and maintenance in your mill. Operator driven reliability, alignment, education, and mill processes will be addressed by leading reliability experts. The Young Professionals Program (YP) offers those new to the industry an unbelievable opportunity to gain basic industry knowledge and meet experienced industry leaders. ##SHARELINKS##

|

Are you ready to go further, faster in your safety career? The Certified Occupational Safety Specialist (COSS) class can take you there. The COSS Class is Unique Not only will you learn how to read and understand the OSHA 1910 and 1926 CFRs and help your company avoid OSHA citations that cost millions of dollars, but more importantly, by learning how to work safely on a job site, you can teach your company how to lower fatalities and near misses. Almost 47% of COSS graduates responding to our survey indicate that, since taking COSS, their company's injury rate and/or OSHA recordables have decreased by as much as 25% and others attest to as much as a 100% decrease! Request a Course Outline & Syllabus for more information. The class also addresses the psychology of safety, the true cost of an accident, hazard recognition, how to start up a health and safety program, behavior based safety, system safety, and much more! What Will You Receive? Upon successfully completing the class, you will obtain your national Certified Occupational Safety Specialist (COSS) designation, your OSHA 10-hr. card of completion in construction, and your OSHA 10-hr. card of completion in general industry. National Program Recognitions COSS is currently one of only 37 programs in the world recongnized and accredited by the American Petroleum Institute (API). In addition, the certifying body for construction education for colleges, universties and technical/trade schools, American Council for Construction Education (ACCE), has also recongnized our program. COSS is the only non-degree program to receive this national endorsement. Lastly, COSS has been established as a mandatory course for students in the Construction Management Program at Louisiana State University. Program Content The program consists of 40 hr. of hands on, face-to-face learning, which is delivered by an Authorized OSHA outreach trainer in both construction and general industry. Case studies and workshops are used extensively to bring learning objectives into focus. Guest speaker from areas such as OSHA and other governmental agencies are used to enhance the learning experience. Student presentations, daily quizzes, practical reviews, and a comprehensive final exam will allow you to demonstrate your competency. Prerequisites The only prerequisite for the COSS class is you must have a high school diploma or equivalent. In each class, we tend to have a mix of non-experienced, first time safety persons, as well as safety professionals who have been in the safety field for 20+ years. But, we have learned that regardless of the numbers of years of experience you have in safety, everyone leaves the COSS class with a wealth of knowledge! Visit the COSS website for FAQs, testimonials and a list of clients that have taken COSS. Register now. If you would like more information on the COSS program, contact Beth Gordon at 877-610-2677 ##SHARELINKS##

|

|

A Call for Papers is underway for these three co-located events: The 2013 TAPPI PEERS Conference, September 15-18, 2013 in Green Bay, Wi., USA has announced the Call for papers. PEERS is the perfect forum for paper industry professionals both to acquire practical operating insights and to network with industry peers in technical sessions, tutorials, round tables, new technlogy sessions and workshops. Suggested topics and more information now available. Deadline for abstracts is March 1, 2013. An Invitation to Present has been announced for TAPPI's 2013 International Bioenergy and Bioproducts Conference (IBBC), September 18-20, 2013 Green Bay, Wi., USA. IBBC is the only event dedicated to advancing biorefineries in the forst product industries, and for the first time will be ehld in the Midwest, providing an expanded focus on activities in Wisconsin and surrounding areas. Suggested topics and more information now available. Deadline for abstracts is March 1, 2013. The International Program Committee for the 10th Research Forum on Recycling announces an Invitation to Present at the 2013 event, September 16-18, 2013 in Green Bay, Wi., USA. Research engineers, scientists, and practitioners are encouraged to submit presentation proposals on all aspects of recycling technologies and operations. Submissions describing both basic and applied research results will be considered. This year's event will provide participants an extraordinary opportunity to hear about the latest in recycling research, discuss mill operation issues, network with peers, and identify future research needs of the recycling community. Deadline for abstracts is March 1, 2013. Learn more. ##SHARELINKS##

|

|

David Schirmer, Vice President and General Manager of Hearst Enterprises will Keynote at Tappi's Shipping Receiving and Warehousing Workshop this April in Nashville. Schirmer is responsible for paper procurement for divisions of Hearst Corp. including Hearst Magazines and Hearst Newspapers and is one of principles of Newsprint Purchasing LLC. Tappi's SRW Workshop, taking place April 9-10, focuses on reducing in-transit paper roll damage through collaborative discussions and best practices. Learn more about SRW. ##SHARELINKS##

|

|

Paper Roll Damage Expensive? Attend TAPPI's SRW Workshop this April and be a part of this dedicated group of mills, carriers, warehouses and printers as they collaborate to reduce in-transit damage to rolls of paper. The Shipping, Receiving and Warehousing Workshop is an affordable working meeting with presentations and collaborative discussions, engaging keynote speakers, and great opportunities for networking. It's something you can't afford to miss. Why attend?

##SHARELINKS##

|

The International Mechanical Pulping Conference, sponsored by PI, TAPPI, PAPTAC, SPCI and PTF, will be held on June 3-5, 2014, in Helsinki, Finland. IMPC 2014 is a major part of PulPaper, one of the world's most premier pulp and paper exhibitions, coinciding with the 100th anniversary of PI, the Paper Engineers' Association. The Conference Program Committee invites you to submit papers on the following topics:

Authors interested in presenting a paper or a poster on these topics should submit an extended abstract (˜500 words) to impc2014@vtt.fi. Abstracts are due by February 28, 2013. Authors will be notified of acceptance by May 31, 2013 and final manuscripts are due March 31, 2014. If you have any questions, please contact Sari Liukkonen, Chair of the Program Committee at +358 40 586 0384, or by e-mail at impc2014@vtt.fi. ##SHARELINKS##

|

|

TAPPI and NCSU are partnered again for the first of three introductory level courses for industry professionals that cover the entire pulping and papermaking process. The 2013 Hands-On Workshop for Pulp and Paper Basics takes place March 4-8 at North Carolina state University in Raleigh, N.C., USA. This workshop fills to capacity quickly, so reserve your place now so that you can:

This workshop is ideal for new process engineers, manufacturing operators and technicians, sales and service personnel, machine operators, and maintenance personnel -- everyone who wants a better understanding of the pulp and paper business. Don't wait too long to register for the March 4-8 workshop. Two additional courses are being offered at NCSU in June and October for those who aren't able to attend the first event. ##SHARELINKS##

|

|

Strengthen your understanding of the corrugating process, and linerboard and medium performance properties and manufacture with TAPPI's Linerboard Medium & Corrugated Box Manufacture Course, April 15-16, at the Holiday Inn in Neenah, Wis., USA. With an emphasis on helping attendees improve corrugating box performance and runnability, this popular introductory to intermediate level course is ideal for process engineers and operators in linerboard and medium manufacturing facilities and corrugating and converting plants. Instructors Michael J. Kocurek, Professor Emeritus, of Paper Science & Engineering at North Carolina State University, and Jon Porter, Senior Trainer / Process Specialist for Fosber America will address:

Register by March 15 to take advantage of the Early Bird registration discount. Join TAPPI or renew your membership for the best rates! ##SHARELINKS##

|

|

The TAPPI Troubleshooting "Flexos" and "Die Cutters" Sustain Board Caliper & Improve Printing Course is scheduled for April 16-18, 2013, in Neenah, Wis., USA. Join industry veteran Dick Target, founder of On Target Consultants, as he helps attendees identify and address downtime issues and develop a better understanding of machine calibration and how to maintain proper board caliper during the converting process. Target will use an easy to understand format to help attendees improve the basic manufacturing process. Topics will include: methods to minimize caliper loss in the converting process; one-box set-up techniques; and waste reduction techniques. View the course schedule. Take advantage of the Early Bird Registration discount before March 16. Join TAPPI or renew your membership for the best rates! ##SHARELINKS##

|

The Secret, Second Edition What Great Leaders Know and Do By: Ken Blanchard & Mark Miller

At one time or another, everyone in a position of authority-whether in a multinational corporation or a local volunteer group-wonders what the key to great leadership is. And who better to answer that question than the team of Ken Blanchard, whose books on leadership have sold over 20 million copies, and Mark Miller, who worked his way up from line worker to vice president of one of the largest fast-food chains in the country. In The Secret, Blanchard and Miller use the uniquely accessible "business fable" format that Blanchard pioneered to get at the heart of what makes a leader truly able to inspire and motivate people. Debbie Brewster, recently promoted and struggling, finds herself about to lose her job due to poor performance. In an attempt to save her career, she enrolls in a new mentoring program offered by her company. Much to her surprise, Debbie finds her mentor is none other than Jeff Brown, the president of the company. Debbie decides that she is going to ask her new mentor the one question she feels she desperately needs answered: "What is the secret of great leaders?" Jeff's immediate answer-that great leaders serve their followers-completely flummoxes Debbie. Over the next 18 months, Jeff helps Debbie discover and explore five fundamental ways that leaders lead through service. The Secret puts what Blanchard and Miller have learned about leadership in a form that anyone can easily understand, embrace, and pursue. It is a book that will benefit not only those who read it, but also the organizations they work in an the people who look to them for guidance. The second edition includes revised and updated content including:

Item #: 12SECRET View the Table of Contents and Preview. Member Price: $23.00 ##SHARELINKS##

|

|

Panelists: ##SHARELINKS##

|

By: Jerome M. Gess and Paul H. Wilson This book takes the reader through the process of making paper, pointing out where interruptions can occur and where elements added to the system can cause problems in that part or subsequent parts of the papermaking process. The aim of this book is to give papermakers and those involved in the papermaking process the information required to allow them to understand how to track down and solve problems at their source rather than where the problems surface. Troubleshooting the Papermaking Process. View the Table of Contents. Product Code: 0101R298 Member Price: $106.00 Non-member Price: $161.00 ##SHARELINKS##

|

Robert (Bob) Vyse has been named the recipient of TAPPI's 2013 Gunnar Nicholson Gold Medal Award, the highest honor that the Association can bestow upon an individual. The award will be presented to Vyse at the

Robert (Bob) Vyse has been named the recipient of TAPPI's 2013 Gunnar Nicholson Gold Medal Award, the highest honor that the Association can bestow upon an individual. The award will be presented to Vyse at the