Over the Wire

TAPPI

|

Forest, paper, and packaging (FPP) CEOs are less confident about revenue growth over the next 12 months than their peers in other sectors, but are more optimistic about their company's revenue prospects in the next three years, according to the PricewaterhouseCoopers (PwC) 16th Annual Global CEO Survey released recently in Davos, Switzerland.

"The CEOs of forest, paper and packaging companies are a resilient bunch. Recently they've faced challenges such as shifting demand and markets, a bumpy economy, overcapacity, environmental issues, and rising costs," said Bruce McIntyre, leader of PwC's Forest, Paper and Packing practice in Canada . "CEOs have identified their top three priorities—enhancing operational effectiveness, investing in innovation and R&D, and developing new business models." McIntyre notes that "FPP CEOs are intensely focused on trimming any fat from operations." The survey found 92% of sector CEOs have implemented a cost-reduction initiative in the past 12 months, and 89% are planning to in the coming 12 months. This result is higher than the overall average of 70% of CEOs across all sectors in the PwC survey. Some of the cost reduction reported was through staff cuts, which are expected to continue, with 18% of FPP CEOs reporting plans to cut their workforce by more than 8% this year. R&D and innovation is a top priority for 42% of FPP CEOs in the next 12 months—a full 10% higher than the overall average across the entire CEO Survey. Almost three-quarters of the FPP CEOs said they will make changes to increase capacity for innovation and R&D. Half of the FPP CEOs surveyed have entered into a new strategic alliance or joint venture in the past year, 34% completed a cross-border M&A, and 32% completed a domestic M&A. "The high degree of transactions and partnerships reflects the broadening uses being found for fiber such as bioproducts, biofuels, and textiles." CEOs reported plans to conduct even more deals in the coming 12 months, with 58% contemplating a strategic alliance or joint venture, 47% a cross-border M&A, and 34% a domestic M&A. Other key findings from the FPP CEO Survey include:

"While trends for the FPP sector are very similar in Canada to those found worldwide, there are some notable differences," McIntyre concludes. "We don't think staff reductions will be as severe in Canada; in fact, we're hearing concern from some Canadian forest products companies about the looming shortfall of qualified labor. If the U.S. housing market rebounds and demand from China continues to grow, we could have a labor shortage in Canada." For PwC's 16th Annual Global CEO Survey, 1,330 interviews were conducted in 68 countries during the last quarter of 2012, including 38 FPP CEOs in 15 countries. This year's survey looked at key items on CEO agendas around the world including confidence in growth, current threats like the availability of talent, approaches to leadership, and the need to rebuild trust. By region, 449 interviews were conducted in Asia Pacific, 312 in Western Europe, 287 in North America (including 120 in Canada and 167 in the U.S.), 165 in Latin America, 95 in Central and Eastern Europe, 50 in Africa, and 32 in the Middle East. The full survey is available online. ##SHARELINKS##

|

|

Domtar Corp., Montreal, Que., Canada, reports that it has successfully installed a commercial-scale lignin separation plant at its Plymouth, N.C., USA, mill, the first U.S. facility of its type in more than 25 years. The production of BioChoice™ lignin began in February, with a targeted rate of 75 tpd, destined for a wide range of industrial applications as a bio-based alternative to the use of petroleum and other fossil fuels.

The successful installation of commercial-scale lignin removal capacity at the Plymouth Mill is the culmination of a research and engineering project launched by Domtar in 2010. This project was further boosted when the U.S. Department of Agriculture and the U.S. Department of Energy awarded the company a grant through the Biomass Research and Development Initiative. Domtar's lignin operation sets a new path for the industry and also marks its latest sustainability milestone. "Our vision is to be a global leader in fiber-based innovation," said Bruno Marcoccia, Domtar's director of research and development. "A big part of this is our focus on partnering with best-in class collaborators to develop new products and markets for a wide portfolio of initiatives, like BioChoice." Hasan Jameel, a professor in North Carolina State University's Department of Forest Biomaterials, noted that "the possibilities for making a real difference in terms of offering manufacturers a bio-based alternative to the use of petro-chemicals is truly exciting. This is a big win for sustainability on two counts—Domtar improves the efficiency of its pulp-making process, and at the same time the market gets a reliable, high-quality source of this underused material with so much potential." A wide range of potential applications for BioChoice lignin exists, including fuels, resins, and thermoplastics. Domtar produces a wide variety of fiber-based products including communication papers, specialty and packaging papers, and adult incontinence products. The foundation of its business is a network of wood fiber converting assets that produce paper grade, fluff, and specialty pulps, the majority which is consumed internally to manufacture paper and consumer products. In 2012, Domtar had sales of $5.5 billion from nearly 50 countries. It employs some 9,300 people. ##SHARELINKS##

|

|

Session T1 at PaperCon's Tissue360o Forum, April 29 - May 1, 2013, in Atlanta, Ga., USA, will define, dissect, and analyze the global tissue and hygienic products market, setting the stage for seven intensive technology sessions that follow over the next three days—chemistry, fiber, advanced production systems, water and energy, controls and measurement, yankee dryer, and converting developments. Sponsored by TAPPI's newest print publication, Tissue360o magazine, these eight Tissue Forum sessions provide the most comprehensive exploration of emerging market drivers and technology developments available anywhere for understanding and meeting challenges of the rapidly evolving tissue and hygienic products industry.

Uutela notes that the tissue business is booming today after recovering quickly and strongly from the 2009 recession. Globally, tissue consumption approached 32 million metric tpy in 2012 and for the first time exceeded the volume of newsprint. RISI expects the long-term growth to continue at an annual average rate of 4% or slightly above. During the past 10 years, China has been the prime motor for growth in the global paper and board industry, and so also in the tissue business, followed by Latin America, which also has shown strong expansion. In the next 10 years, large emerging markets such as Brazil, Turkey, and Russia will increasingly offer tissue companies new business opportunities. The North American tissue market is experiencing a new investment boom this year, expected to continue through 2014, Uutela continues. This time the main driver for new projects seems to be the need for ultra and premium grade tissue, partly as a reflection of major retailers' target to upgrade their private label offerings closer to the main brands in quality, although there is a clear trend toward higher quality in the away from home sector as well. "Market growth has flattened, particularly in terms of weight as the product light-weighting trend continues. Competition does not show any signs of alleviation, and it's amazing to see how a growing number of small, independent converters have been able to forge ahead based on their niche products, flexible service, and sub-contracting orders from the big players," Uutela says.

In her presentation, Gervais explores the combination of falling yields and rising costs of SOP (sorted office paper) to determine a breakeven cost of manufacture when compared with a virgin fiber furnish. She examines the impacts of this key issue and takes a look at other fiber resources and their future role in tissue manufacturing. More information about PaperCon 2013 is available online, including online registration. Additional information about the Tissue360o Forum program is also available online. ##SHARELINKS##

|

|

DreamWeaver International, Greenville, S.C., USA, and P.H. Glatfelter Co., York, Pa., have formed a partnership to develop and manufacture the next generation of high performance and affordable separators targeted for energy storage devices such as lithium-ion batteries and ultra capacitors. With this partnership, DreamWeaver will be able to leverage Glatfelter's state-of-the-art inclined wire capabilities and expertise in making advanced fiber-based engineered materials.

Glatfelter continues to optimize the use of its eight inclined-wire machines to produce a diverse range of products, including, non-woven energy storage materials for the capacitor and lead-acid battery markets. These new fiber-based materials possess superior porosity and excellent web uniformity in low basis weight and thickness. DreamWeaver battery separators combine microfibers and nanofibers in a porous substrate, which is ideal for battery separation application. DreamWeaver Silver™ is a general purpose product with excellent power capability and DreamWeaver Gold™ has very high temperature stability (up to 300oC) without significant thermal shrinkage. The partnership will focus on developing and manufacturing the current generation of DreamWeaver products and jointly developing future generations. "DreamWeaver's technology is a natural fit, allowing us to extend our presence in the growing energy storage market with innovative and proprietary technology," said Martin Rapp, VP and GM of Glatfelter's Composite Fiber Business Unit. "Glatfelter offers over a century of experience in manufacturing advanced web materials. This collaboration aims at developing and producing the next generation of high quality, competitively priced material demanded by the energy storage market," said Dr. Brian Morin, DreamWeaver's president and COO. "We believe Glatfelter has the capability needed to serve our customers, with the right mix of technological expertise, manufacturing capability, and foresight to help us become a leading supplier of battery separators worldwide." ##SHARELINKS##

|

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013, in Atlanta, Ga., USA, and co-located with 2013 PaperCon and the Tissue Forum. Both the Tissue Forum and Tissue Properties & Manufacturing Course are being sponsored by TAPPI's Tissue360o magazine.

This is a great opportunity to get the most out of your conference experience. The Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties, and the effect of manufacturing. This course precedes the Tissue 360° Forum at PaperCon, and is an excellent educational compliment to these technical sessions. The course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters, and marketers with 0-5 years of experience in tissue manufacturing. More information about the Tissue Properties & Manufacturing Course is available online. ##SHARELINKS##

|

|

The OpEx Maintenance and Reliability Workshop at TAPPI PaperCon 2013 in Atlanta, Ga., USA, on April 30, will include a special joint session with the Recycled Paper Trade Association (RPTA) that explores Operator Driven Reliability (ODR) from an up-close, mill case-study perspective. During this session, Christer Idhammar with IDCON examines what has been tried with ODR, who's succeeded, what's failed, and why—all based on mill case study results.

Also during the joint session, Tony Kenneson-Adams of RockTenn will look in-depth at how his Solvay recycled containerboard mill in Syracuse, N.Y., set up its ODR program and the pitfalls they experienced along the way. Rounding out the joint OpEx/RPTA session, Jim Davis of Performance Consultants Associates illustrates how to effectively support ODR programs by building "The Perfect Maintenance Storeroom." More information about PaperCon 2013 and the OpEx Maintenance and Reliability Workshop, including registration procedures, is available online. Also available online is the 2013 OpEx Workshop program. ##SHARELINKS##

|

|

Below is the latest listing of job openings in the TAPPI Career Center. The current listing includes job openings for a variety of positions including process engineers, power and recovery assistant superintendent, chief engineer, executive director, production manager, sales manager, mill manager, engineering intern, and HR manager. Specific job openings at companies and locations in the TAPPI Career Center include:

More information about these jobs is available online. ##SHARELINKS##

|

|

Wood fiber prices trended downward in local currencies in many of the key pulp-producing countries of the world in the fourth quarter of 2012, according to the report Wood Resource Quarterly (WRQ), Seattle, Wash., USA. However, as a result of the weakening U.S. dollar, wood fiber prices actually increased in U.S. dollar terms in a number countries and the Softwood Wood Fiber Price Index (SFPI) was up slightly (+0.1%) in the 4Q/12 to $100.13/odmt. The biggest increases from the 3Q to the 4Q occurred in Eastern Canada, Finland, France, and New Zealand.

Price declines in local currencies were mainly the result of an increased supply of softwood fiber in regions with extensive lumber production. In the U.S. Northwest, chip prices fell as much as 27% during 2012 and pulp mills in the region had some of the lowest softwood fiber costs in the world in the 4Q/12. Additional volumes of residual chips from increased lumber production, reductions in pulp production and pulp mill outages, and large supplies of pulp logs were all factors that contributed to the dramatic turnaround in fiber costs during 2012. A similar trend was seen in Western Canada, where prices in the 4Q/12 were down 22% from late 2011, reaching their lowest levels in three years. Hardwood fiber price movements were mixed, with hardwood pulp log prices generally trending downward in many of the key hardwood pulp-producing regions in both local currencies and in U.S. dollar terms. This resulted in a decline in the Hardwood Wood Fiber Price Index (HFPI) to $104.80/odmt in the 4Q/12. This was down 1.5% from the previous quarter and 7.8% from the 4Q/11. The biggest decline in hardwood fiber prices occurred in Brazil where Eucalyptus log prices have fallen continuously for more than a year from early 2011, when they were at their all-time highs. In the 4Q/12, prices in U.S. dollar terms were back down to the same levels as in early 2009. Few regions in the world currently have lower hardwood costs than Brazil. More information is available online. ##SHARELINKS##

|

|

Cascades Tissue Group, Candiac, Que., Canada, this past week announced that its Antibacterial paper towel has secured a "4-Star" Environmental Leader Technology Review Score and has been named a 2013 Edison Awards Finalist in the Consumer Packaged Goods: Cleaning Solutions category. The paper towel was launched in 2010 in the Canadian Away-from-Home market and in 2012 in the U.S.

The Antibacterial paper towel provides a simple and effective way to further reduce bacterial contamination and transmission, Cascades notes, pointing out that it almost instantly kills more than 99.99% of harmful bacteria. By integrating a safe active ingredient into a dry format, the green-colored paper towel compensates for people's imperfect hygiene habits without changing how they wash or dry their hands. "We are honored the Cascades Antibacterial paper towel is gaining such tremendous recognition among so many other great products and services," said Suzanne Blanchet, CEO of Cascades Tissue Group. "While our Antibacterial paper towel breaks new ground in terms of innovation, we're also very excited about the positive social impact it can have on human health. Without even changing habits, everyone can now help control the spread of bacteria." ##SHARELINKS##

|

|

CMPC Celulose Riograndense, Brazil, has awarded Pöyry, Finland, the engineering, procurement, and construction management (EPCM) services for the balance of plant (BOP) in the expansion of its Guaiba pulp mill in Rio Grande do Sul state, Brazil. The assignment consists of and involves integrating the different processes of the mill. The engineering and project management services, the value which has not been disclosed, will start immediately.

The capacity of the new state-of-the-art pulp mill is 1.3 million metric tpy, and the startup is planned for the first quarter of 2015. The bleached eucalyptus pulp production line is the largest investment in CMPC's history. Pöyry has been involved in the project since October 2010, when CMPC awarded it an assignment for feasibility studies and basic engineering. The company was also awarded preparatory work for the mill infrastructure. Now Pöyry will be responsible for overseeing that the different parts of the plant will be efficiently developed and connected together. ##SHARELINKS##

|

|

For the seventh straight year, International Paper, Memphis, Tenn., USA, was named as one of the World's Most Ethical Companies by The Ethisphere Institute, New York, N.Y. Despite a record number of global nominees, IP secured a spot on the list by maintaining its focus on the ethical business practices and standards that have defined the company since its inception more than 100 years ago.

"This is an important recognition that encompasses all that we do at International Paper. We are a company of substance in the more than 24 countries where we operate – and we are strengthened by the results of our employees who do the right things for the right reasons," said Chairman and CEO John Faraci. Alex Brigham, executive director of Ethisphere, noted that "not only did more companies apply for the World's Most Ethical Companies recognition this year than any year in the past, which demonstrates that ethical activity is an important part of many of these companies' business models, but we are also seeing more companies be proactive and create new initiatives that expand ethics programs and cultures across entire industries, such as industry-based ethics associations and other activities." Through in-depth research and a multi-step analysis, Ethisphere reviewed nominations from companies in more than 100 countries and 36 industries. The methodology for the World's Most Ethical Companies includes reviewing codes of ethics, litigation, and regulatory infraction histories; evaluating the investment in innovation and sustainable business practices; looking at activities designed to improve corporate citizenship; and studying nominations from senior executives, industry peers, suppliers, and customers. IP is a global producer of packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia, and North Africa. Its businesses include industrial and consumer packaging and uncoated papers, complemented by xpedx, the company's North American distribution company. The company employs some 70,000 people and is strategically located in more than 24 countries. Its net sales for 2012 were $28 billion. ##SHARELINKS##

|

The first state-of-the-art tissue machine in Morocco has started up at Jeesr Industries in Berrechid, close to Casablanca. The Metso-supplied Advantage DCT 100+ line smoothly came on stream according to plan and has been producing high quality paper from the very start. The first state-of-the-art tissue machine in Morocco has started up at Jeesr Industries in Berrechid, close to Casablanca. The Metso-supplied Advantage DCT 100+ line smoothly came on stream according to plan and has been producing high quality paper from the very start.

"This investment is very important to us and we are of course pleased to see that the machine is operating according to our targets and that Metso have fulfilled our expectations," Souheil Badaa, chief marketing officer, Novatis Group, said. Jeesr Industries is a privately owned company, which is part of the Novatis Group, a producer and supplier of various consumer goods, including baby diapers, for the Moroccon market. "We are very satisfied with what the Jeesr team and Metso have achieved here. The facility has a compact and efficient layout and both of our crews have done a great job to ensure a smooth startup as well as a continued optimal production," Gunnar Söderqvist, project manager, Metso, noted. Metso's delivery included a complete production line with stock preparation equipment, an Advantage DCT 100+ tissue machine, and a rewinder and wrapping equipment. The production line is optimized to produce top-quality tissue paper at low energy and water consumption levels. The delivery also includes an extensive automation package with Metso DNA machine, process, and integrated drive controls and a Metso IQ quality control system with Metso IQ Fiber Weight Measurement. The new production line is designed to produce around 30,000 metric tpy of high-quality facial, toilet, and towel grades mainly for the Moroccon market. The raw material for the new line is virgin pulp. In the photo (l-r), in front of the first tissue roll from the new line, are Abdallah Badaa, president and CEO of Novatis/Jeesr Group, Souheil Badaa, chief marketing officer of Novatis/Jeesr Group, and Khalid Berbiche, deputy GM of Jeesr Industries. ##SHARELINKS##

|

|

The Ethisphere Institute, New York, N.Y., USA, this week announced that Kimberly-Clark Corp., Dallas, Texas, has again ranked among the "World's Most Ethical Companies" in 2013. K-C received multiple honors and awards for its governance, citizenship, and sustainability practices over the past year, which further supported this week's Ethisphere ranking:

"At Kimberly-Clark, we strive to live a culture of integrity in all that we do," said Tom Falk, chairman and CEO of Kimberly-Clark. "This distinction from Ethisphere reflects on the actions of more than 58,000 Kimberly-Clark employees worldwide who pursue authenticity, accountability, innovation, and caring in countless business decisions every day. I am grateful for this opportunity to recognize their efforts." The research-based Ethisphere Institute is an international think-tank dedicated to the creation, advancement, and sharing of best practices in business ethics, corporate social responsibility, anti-corruption, and sustainability. Ethisphere Magazine, which publishes the globally recognized World's Most Ethical Companies Ranking, is the quarterly publication of the Institute. ##SHARELINKS##

|

|

Metsä Group, Finland, reports that the new gasification plant at its Joutseno pulp mill in Finland started up this past week. The Joutseno pulp mill is the world's largest single-line softwood pulp mill.

The company notes that the new gasification plant improves the efficiency of renewable energy usage by replacing natural gas used with biofuel made from tree bark. The gasification plant makes the pulp mill the first carbon dioxide-neutral facility in Finland during normal operations. Technology used in the gasification plant is a new application for the Finnish pulp industry. The innovative and comprehensive solution uses surplus heat from the mill in drying tree bark. The plant considerably improves the mill's energy-efficiency and further improves the mill's environmental performance. Similar development work is under way at Metsä Fibre's other mills as well, and all Metsä Fibre's mills will become carbon dioxide-neutral in the coming years. Metsä Fibre is a significant supplier of bioenergy in Finland. Its mills account for approximately one fifth of all wood-derived electricity generated in Finland. ##SHARELINKS##

|

|

Resolute Forest Products, Montreal, Que., Canada, this week announced the indefinite idling of a newsprint machine at its Calhoun, Tenn., USA, mill. The idling comes as a result of a decrease in demand for newsprint, coupled with high operating costs for the machine, which produced 215,000 metric tpy. The decision follows Resolute's March 11 acquisition of the 49% interest in Calhoun Newsprint Co. owned by The Herald Publishing Co., its joint-venture partner.

The Calhoun mill, which currently employs 610 workers, will continue to operate the two specialty paper machines and the pulp dryer. The announcement will affect approximately 150 positions at the mill. The company will provide severance to affected employees according to the local labor agreement or the corporate policy for salaried employees. Outplacement assistance will be made available through government agencies. Resolute owns or operates more than 40 pulp and paper mills and wood products facilities in the U.S., Canada, and South Korea, and power generation assets in Canada. ##SHARELINKS##

|

|

Sappi Fine paper Europe and SCA Hygiene Products, Stockholm, Sweden, have joined forces in the field of wood sourcing in Germany. Both SCA and Sappi are holding a 50% share in the joint venture that will be rebranded proNARO GmbH and move its registered office from Hönsbach, Germany, to Stokstadt, Germany.

proNARO is strategically focused on the wood sourcing process of pulp operations in Alfeld, Stockstadt, Mannheim, and Ehingen in Germany and is also involved in biomass activities. The annual buying volume is 2.8 million solid cubic meters of wood. "This is another meaningful step in the co-operation between SCA and Sappi and secures a wood supply on a long-term basis for our pulp production in a cost efficient, sustainable, and professional way," said Randy Rotermund, director Supply Chain & Procurement of Sappi Fine Paper Europe. "Wood as a raw material is the most important cost factor for pulp production and therefore of immense meaning for the industries' competitiveness. Cooperation with Sappi opens up new possibilities and chances for our wood sourcing organization and logistics and provides significant cost savings," added Andy Woodburn, VP of SCA's Supply Tissue Business Unit, AFH Professional Hygiene Europe. ##SHARELINKS##

|

|

SCA, Stockholm, Sweden, has been recognized for the sixth consecutive year by Ethisphere as one of the 2013 World's Most Ethical Companies. The annual list from leading international think-tank Ethisphere Institute highlights organizations that show leadership in promoting ethical business standards. The 2013 WME companies are those that truly embrace ethical business practice and demonstrate industry leadership, forcing peers to follow suit or fall behind.

"At SCA we push beyond statements about how we do business ethically and translate those words into actions every day. That means we demonstrate respect for the environment by investing in sustainable business practices and we follow a detailed code of conduct in the way we work with employees, our customers, and our suppliers," said Don Lewis, president of SCA Americas. "We are proud and honored that the ethical foundation our company is built on has been recognized with a place on the World's Most Ethical Companies list for the sixth consecutive year. This recognition signifies our deep commitment to ethical business practices and the unwavering dedication to these same high standards from employees at every level." Out of a record number of nominations for the award, SCA earned the coveted recognition by implementing and maintaining upright business practices and initiatives that are instrumental to the company's success, benefit the community, and raise the bar for ethical standards within the industry. The 2013 list is the largest list since the award's inception in 2007. SCA is a global hygiene and forest products company that develops and produces sustainable personal care products, tissue, and forest products. With sales in 100 countries, SCA has 37,000 employees and had revenue in 2012 of $13 billion. With nine manufacturing facilities across North America, the company's Americas headquarters is in Philadelphia, Pa., USA. ##SHARELINKS##

|

|

Wausau Paper, Mosinee, Wis., USA, this week reported to have reached an agreement with Starboard Value LP and its affiliates regarding the composition of the company's board of directors. Wausau has agreed to nominate two new directors recommended by Starboard, John S. Kvocka and George P. Murphy, neither being employed by or affiliated with Wausau or Starboard. The nominations will be included in the company's 2013 proxy statement and submitted for stockholder approval at the company's 2013 Annual Meeting.

In connection with the nominations, Starboard, which owns approximately 14.8% of the outstanding shares of Wausau's common stock, has agreed to vote all of its shares in favor of each of the board's nominees at the 2013 Annual Meeting. A total of four director nominees will stand for election at the 2013 Annual Meeting, including the two Starboard recommended candidates. If all nominees are elected, the Wausau Board will be expanded to nine directors, comprised of seven independent directors, Thomas J. Howatt, non-executive chairman of the board, and Henry C. Newell, Wausau's president and CEO. The board is presently comprised of eight members. Dennis Kuester, having attained the mandatory age of retirement, will not stand for election at the company's 2013 Annual Meeting. "We are pleased to have reached this agreement with Starboard," said Hank Newell, president and CEO of Wausau Paper. "Wausau Paper is well positioned to capitalize on the investments we have made in the tissue business and we look forward to working productively with our new board members, John Kvocka and George Murphy, with a shared commitment to enhancing stockholder value. We are confident that their significant industry experience will be an asset to Wausau." Jeff Smith, CEO of Starboard, said that "we are pleased to have worked constructively with management and the board of Wausau and are confident that the addition of John Kvocka and George Murphy will bring a fresh perspective to the board and serve the best interests of Wausau and its stockholders. We look forward to enhanced value for the benefit of all stockholders." Wausau Paper produces and markets specialty papers for industrial, commercial, and consumer end markets as well as a complete line of away-from-home towel and tissue products. ##SHARELINKS##

|

|

Iggesund Paperboard, Sweden, producer of the paperboard Invercote, is inviting designers from around the world to participate in a unique learning experience. From those who apply, 20 will be chosen to join the Iggesund Design Experience in Sweden in late August of this year.

"We tried this for the first time in 2012 and the appreciation and enthusiasm we got from the participating designers was overwhelming. So we'll do it again", says Staffan Sjöberg, public relations manager at Iggesund Paperboard. Participants will visit the Swedish forests to discover more about how they function and are managed, and they will see how paperboard is made. They also will find out how they can use paperboard to raise their creativity to new heights while also making the right choices from a sustainability standpoint. The Iggesund Design Experience will discuss sustainable design and material selection and will question experts in such fields as forest management, water pollution/purification, and food safety in packaging. Participants will return home with new insights into how to make their designs stand out from the crowd not only graphically but also from a sustainability point of view, Iggesund explains. "We usually receive significantly more applications to our events than we can accommodate. To ensure a wide range of participants, we must therefore create a shortlist based on such factors as design speciality and geographic location," Sjöberg notes. Iggesund Paperboard will be the host for four days filled with experiences of nature, insights into product knowledge, and discussions about sustainability, together with fellow designers from around the world. The event itself will be completely free of charge but participants will need to pay their own travel expenses to and from Stockholm, Sweden. "The designers will invest their time—and in return we will give them some unforgettable days in the heart of Sweden," Sjöberg says. This new activity was inspired by the huge response Iggesund received from the design world for its Black Box Project, which gave well-known designers free rein to create unique solutions using Invercote as a starting material. More information and a registration form for the Iggesund Design Experience are available online at In the photo, a group of international designers visits a nursery where a major part of Iggesund's more than 30 million annual seedlings are being grown.

##SHARELINKS##

|

|

Orient Paper, Inc., Baoding, China, a producer of diversified paper products in North China, reports that it has begun finalizing the renovation plan for its existing 150,000 metric tpy corrugating medium production line. The width of the machine will be expanded from 3.2 meters to 5.6 meters, and production capacity will be expanded to 250,000 metric tpy.

In preparation for the construction, Orient Paper said that it will demolish certain facilities. It expects to sign the paper machine construction contract with an equipment supplier when the layout design is finalized later this month. Founded in 1996, Orient Paper uses recycled paper as its primary raw material in the production of three types of paper products, packaging papers (corrugating medium), offset printing papers, and other paper products, including digital photo paper, and household/tissue paper that the company is currently expanding into. With production operations based in Baoding in North China's Hebei Province, the company is located strategically close to the Beijing and Tianjin region, home to a growing base of industrial and manufacturing activities and one of the largest markets for paper products consumption in the country. Orient Paper's production facilities are controlled and operated by its wholly owned subsidiary Shengde Holdings, Inc., which in turn controls and operates Baoding Shengde Paper Co., and Hebei Baoding Orient Paper Milling Co., for manufacturing digital photo, printing, and packaging paper. ##SHARELINKS##

|

|

Xerium Technologies Inc., Raleigh, N.C., USA, has announced the full commercial availability of SMART® 5.0 Technology. SMART 5.0 provides real-time nip analysis, including three-dimensional measurement and display of machine direction nip width, advanced capability for shoe press nips, and enhanced connectivity software to connect directly to mill DCS and PI machine control systems.

As Xerium notes, roll covers are critical to the quality and cost of paper as it is produced. Xerium introduced SMART roll cover products in 2008 as the industry's first real-time electronic roll cover. Since then the company has implemented the product line globally and includes it as an available value-add feature of all roll cover types – rubber, polyurethane, and composite. Harold Bevis, Xerium president and CEO, said that "SMART 5.0 is a significant next step in real-time electronic roll covers. The nip is modeled and displayed graphically in 3D so that machine operators can dial in their machines to get maximum results. The data feeds are straight-forward to integrate into overall machine controls. We are well underway with our machine integration approaches. This is a productivity advancement worth looking into." ##SHARELINKS##

|

|

International Paper Co., Memphis, Tenn., USA, reportedly has implemented a $50/ton price increase on solid bleached sulfate (SBS) coated paperboard grades. The increase becomes effective with shipments beginning March 28.

IP is a supplier of packaging and paper with operations in North America, Europe, Latin America, Russia, Asia, and North Africa. Its businesses include industrial and consumer packaging and uncoated papers, complemented by xpedx, the company's North American distribution company. The company employs some 70,000 people and has operations in more than 24 countries. ##SHARELINKS##

|

|

Vaskiluodon Voima Oy, Finland, has inaugurated the world's largest biomass gasification plant, which was supplied by Metso, in Vaasa, Finland. The plant was inaugurated by the Finnish Minister of Labor Lauri Ihalainen this past Monday, March 11.

Vaskiluodon Voima's plant is ground-breaking in many ways, as this is the first time in the world that biomass gasification is being adopted on such a large scale for replacement of fossil fuels. Metso's delivery included fuel handling, a large-scale dryer and a circulating fluidized bed gasifier, modification work on the existing coal boiler, and a Metso DNA automation system. The bio-gasification plant was constructed as part of the existing coal-fired power plant, and the produced gas will be combusted along with coal in the existing coal boiler. The contract for the new plant was announced in June 2011, and Metso started construction at Vaskiluoto in April of the following year, making the actual construction phase fairly short. "The operational experiences so far indicate that the 140-MW bio-gasification plant functions as planned, and the produced gas burns cleanly in the coal boiler and reduces emissions," says Mauri Blomberg, managing director, Vaskiluodon Voima. Nearly half of the coal used by the plant can now be replaced with gasified biomass. This makes the solution highly environmentally friendly, enables the flexible use of different fuels, and significantly extends the life of the current power plant. "The commissioning of the gasification plant is a major step in our company's target of using mainly domestic fuels for heat and electricity production. This can be considered a complete energy turnaround," says Rami Vuola, chairman of Vaskiluodon Voima and CEO of EPV Energia Oy, joint owner of Vaskiluodon Voima. Vaskiluodon Voima Oy is equally owned by the energy companies EPV Energia Oy and Pohjolan Voima Oy. The company's power plants, located in Vaasa and Seinäjoki, produce electricity and district heating. ##SHARELINKS##

|

|

Schweitzer-Mauduit International, Alpharetta, Ga., USA, a producer of specialty papers and packaging primarily for the tobacco industry, announced that Stephen (Steve) Dunmead has joined the company as COO. In this role, Dunmead assumes responsibility for the strategic and operational leadership of SWM's Paper and Reconstituted Tobacco Leaf (RTL) divisions, including the company's global research and development, sales and marketing, operational excellence, and sustainability initiatives.

Dunmead has more than 20 years of operational, technical, and management experience, particularly with companies pursuing growth initiatives. His background includes substantial hands-on experience and expertise in research and technical roles, as demonstrated by the 25 U.S. patents he holds on advanced materials and specialty chemicals. Dunmead was named Inventor of the Year by Dow Chemical in 1994 and again in 1996. According to SWM's Chairman and CEO Frédéric Villoutreix, "this is a very exciting time for SWM. Our Paper and RTL businesses have very good growth opportunities over the next several years, including the ramp-up of capabilities in China, with our second joint venture expected to open in 2014. In addition, this change will help to better focus our resources on innovation and organic growth opportunities in non-tobacco market adjacencies that already comprise a portion of our revenue base. This includes highly engineered products supporting electrical, laminating, filtration, and medical applications. Adding Steve to our team augments our internal expertise and will help us make the most of these organic opportunities, while keeping a keen focus on our core operations. We are fully committed to ensuring SWM's long-term continued success and maximizing customer and shareholder value. We welcome Steve to our executive team and look forward to his contributions." Otto Herbst, previously COO and EVP of Global Papers, will continue to lead as EVP, managing the company's paper business. ##SHARELINKS##

|

|

Kimberly-Clark Corp., Dallas, Texas, USA, has named Clive Sirkin VP and chief marketing officer, reporting to Tony Palmer, president of global brands and innovation. Sirkin joined K-C in 2007 and has held a number of marketing leadership positions.

"Since joining K-C, Clive has been instrumental in building strong, healthy brands and businesses around the world," Palmer said. "As CMO, Clive will continue the ongoing transformation of our marketing function as a core driver of our growth agenda." A native of South Africa, Sirkin graduated from the University of Witwatersrand in Johannesburg with a bachelor of commerce degree in economics and marketing. He spent the first part of his career in finance and operational roles. In 1989, Sirkin joined advertising giant Leo Burnett and spent the next 16 years in a variety of increasingly responsible roles, ending his time at the agency as group managing director, Leo Burnett Worldwide. Prior to joining K-C, Sirkin consulted with consumer packaged goods firms and specialized in helping clients transform marketing processes to commercialize their brands more effectively and efficiently. ##SHARELINKS##

|

TAPPI member Nick Triantafillopoulos, Ph.D., says he believes strongly in one's "ethical obligation to give back through service," especially to an organization that has played a pivotal role in your career. That's why he has been an active member since 1981 when he was just beginning his pulp and paper career path and eager to make a difference in the industry he loves. "Membership has meant an opportunity to develop not only technical and leadership skills, but also a network of technical experts and friends." This tight-knit relationship with his profession and TAPPI is still going strong. "Part of engaging in TAPPI is the opportunity to play a leadership role in volunteerism," he said. Besides teaching training courses, organizing symposia, progressing through committee chairs, writing a division newsletter, and editing articles for TAPPI Journal, Nick says helping to execute change in the volunteer programs taught him the inherent challenges and satisfaction of seeing a new, morphed organization created. Find out more by reading this month's Member Spotlight. Spotlight participants are recommended by fellow members and staff. If you would like to nominate a member just send his or her name (or names) to MemberSpotlight@tappi.org. We will forward a Spotlight Questionnaire to fill out and return. We look forward to seeing you in the Spotlight! ##SHARELINKS##

|

|

Nominations for the major TAPPI 2014 awards are due by August 1, 2013. The awards that may be presented in the upcoming year are: Gunnar Nicholson Gold Medal Award - The Association's highest technical honor may be presented annually to recognize an individual or individuals for preeminent scientific and engineering achievements of proven commercial benefit to the world's pulp, paper, board, and forest products industries and the other industries that TAPPI serves. Herman L. Joachim Distinguished Service Award - The Association's highest award for service may be presented annually to recognize leadership and service that have significantly and demonstrably contributed to the advancement of the Association. Paul W. Magnabosco Outstanding Local Section Member Award - The highest honor for Local Sections may be presented annually to recognize an individual for outstanding leadership and exceptional service to one or more Local Sections, which have resulted in significant and demonstrable benefits to the Local Section members. TAPPI Fellow - TAPPI Fellows are individuals who have been members of TAPPI for not less than 10 years prior to the nomination, and who have contributed meritorious service to the Association and/or the paper and related industries. Retiring members of the TAPPI Board of Directors become Fellows automatically at the end of their term. The TAPPI Awards and Honors page has links to these awards that will show the qualifications required and links to the nomination forms that must be completed. You may submit all nomination forms by email to standards@tappi.org, or you may fax them to the attention of the awards department at +1-770-446-6947, or send them by mail to TAPPI, Awards Department, 15 Technology Parkway South, Peachtree Corners, GA 30092, USA. ##SHARELINKS##

|

|

The TAPPI - PPSA Safety Management Leadership course is designed to build leadership commitment and engagement for a culture of safety excellence. This partnership with the Pulp & Paper Safety Association brings you the best safety practices in the industry. The Safety Management Leadership Course will be held April 10-11, 2013, at the TAPPI Training Facility in Peachtree Corners, near Atlanta, Ga., USA. This course delivers curriculum to help you learn the fundamentals of record-keeping, incident investigation, risk management, cultivating a safety culture, managing change safely, and measuring performance. Take a look at the expert panel of instructors. The course is designed for anyone that is involved in workplace safety. Course registration is limited to only 20 participants, so please register today at the course website. TAPPI and PPSA members save, and early registration discounts are available. ##SHARELINKS##

|

|

Establishing and Maintaining Effective Labor/Management Committees Thursday, March 28, 2013 12:00 - 1:00 pm EST This is a free webinar, but you must register to attend. Labor management committees (L/M committees) foster better communication, understanding, and enhance labor-management partnerships to enable the management and labor to collaborate on workplace problems in a timely manner. But how do you establish and maintain one? Attend this one-hour webinar and learn how to build consensus, establish the committe, and effectively train members. This webinar is a preview of "Effective Labor/Management Relationships," sponsored by PIMA and PPMA; part of the PIMA Management Program of PaperCon taking place April 28 - May 1 in Atlanta, Ga., USA. Learn more about this webinar. Learn more about PaperCon. ##SHARELINKS##

|

|

##SHARELINKS##

|

|

Tissue360 Forum @ PaperCon 2013 Monday, April 29 - Wednesday, May 1 Atlanta, Ga., USA TAPPI's new Tissue publication, Tissue360o magazine, and TAPPI tissue experts have organized Tissue360 Forum, a comprehensive technical forum covering all aspects of tissuemaking. You will hear about the latest tissue technology, market trends, and pick-up some runnability/operational tips. The program is open to all full PaperCon registrants. Program Overview: Hygenic Products Market Overview Session Chairs: Ken Patrick, Tissue360o Chemistry Solutions for Tissue Making Session Chair: Gary Furman, Nalco Water and Energy Strategies for Tissue Session Chair: Tom Jenn, Kimberly-Clark Premium Tissue Manufacturing Technologies Session Chair: Soren Eriksson, Metso Tissue Controls and Measurement Session Chair: Rene Naranjo, AstenJohnson Yankee Reliability (CEUs provided) Session Chair: Al Coons, Clearwater Paper Converting Efficiencies Session Chair: Kevin Brennan, Ashland Water Technologies See the full Tissue360 Forum program. PaperCon will take place April 27 through May 1, 2013 in Atlanta, Ga., USA. Designed by industry professionals, PaperCon brings together CEOs, mill managers, superintendents, scientsits, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other such event provides such a comprehensive program, networking opportunites, and trade fair among such a distinguished group of industry leaders. Learn more about PaperCon 2013. ##SHARELINKS##

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013 in Atlanta, Ga., co-located with PaperCon 2013 and the Tissue Forum. This is a great opportunity to get the most out of your conference experience. This Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties and the effect of manufacturing. The course precedes the Tissue Forum at PaperCon 2013 and is an excellent educational component to these technical sessions. This course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters and marketers with 0-5 years of experience in tissue manufacturing. Go to the course website to learn more. ##SHARELINKS##

|

|

PaperCon, April 27 - May 1 in Atlanta,Ga., USA, will include two focused, peer-reviewed sessions within the PIMA Management Program that examine recent developments and usage techniques in Information Technology (IT). Session M6: "Traditional DCS and IT Converge: How to Position Yourself to Take Full Advantage of the Opportunities," chaired by Paul Stecher, SVP and CIO, RockTenn, is geared to DCS control engineers, superintendents, and IT support, and will focus on high speed network and traffic isolation approaches, security considerations, and the latest data integration techniques. Session M8: "Using Industry Proven Software Tools to Drive Mill Efficiencies", chaired by Jim Pigott, MAJIQ, will include three presentations: "Integrating Forecasting to Costing in Dollars and Sense" presented by David Pawelke, MAJIQ; "Thoughts on Paper: Connecting the Supply Chain" presented by Jim Black, OSI Soft; and "Vertically Integrated Real-time Costing for Pulp and Paper Mills," presented by Fredric Karlsson, Enterprise Performance Solutions. Learn more about these sessions and the PIMA Mangement Program at PaperCon. Learn more about PaperCon 2013. ##SHARELINKS##

|

|

Introduction to Nonwovens Tutorial Monday, April 29 3:30 - 5:00pm EST This tutorial will be led by Behnam Pourdehimi, executive director of the Nonwovens Institute at North Carolina State University. As far as business segments that are growing and vibrant, the Nonwovens industry certainly meets those criteria. But Nonwovens means different things to different people. The Nonwovens Institute at North Carolina State University will share an insightful tutorial about the industry, what it includes, which areas are mature, and which are growing. This tutorial is part of the NETInc Innovative Nonwovens Conference, April 29 - May 1, in Atlanta, Ga., USA. This is the only technical conference developed by engineers and technologists to help you understand the innovation behind the science and how it impacts the market. Learn more about NETInc. ##SHARELINKS##

|

|

With more than 80 technical presentations and 50 posters, the 2013 TAPPI International Conference on Nanotechnology for Renewable Materials is packed with the latest applications of renewable nanomaterials. The conference will take place June 24-27, 2013, at the KTH Royal Institute of Technology in Stockholm, Sweden. Register by April 29 for the best rates! This year's conference features keynote presentations that focus on the steps needed to deploy emerging nanotechnologies into the bioeconomy. Hear from these recognized global leaders:

Looking for Additional Nanotechnology Events? Check out the TAPPI Flexible Packabing Symposium: New Technologies, preceding the ICE USA Exposition on April 8 at the Orange County Convention Center in Orlando, Fla. Sessions include Innovations in Nanocomposites, Innovations in Barrier, and Brand Launch, Shelf Appeal, and Authentication. Learn more. ##SHARELINKS##

|

|

The TAPPI International Best Practices on the Corrugator Seminar will be held April 9-11, 2013, in conjunction with SinoCorrugated 2013 in Shanghai, China. The three-day course features an in-depth technical program designed to teach participants about each element in the corrugating process and how to improve box plant operations and box quality. The Best Practices on the Corrugator Seminar is an introductory to intermediate level course that teaches participants how to understand each element in the corrugating process and how to run each component with optimum settings for peak performance to increase productivity, improve quality, and minimize waste. Both old and new equipment will be covered. Participants will also develop an understanding of the critical properties of the raw materials that are vital to guarantee acceptable quality board. Among the key topics to be addressed are: theory of corrugated board production and solutions to common operational problems; distinguishing key features of paperboard/starch adhesive and how to control warp; operating the corrugated production line; controlling and minimizing downtime; maximizing production line efficiency and maintaining quality standards. Find out more about the Corrugator Best Practices Seminar. ##SHARELINKS##

|

|

The NETInc Innovative Nonwovens Conference, April 29 - May 1, 2013, in Atlanta, Ga., USA, is the only technical conference developed by engineers and technologists to help you understand the innovation behind the science and how it impacts the world. Program topics include: Nanotechnology, Binders and Additives, Building Sciences, Health Care and Medical Applications for Nonwovens, Manufacturing Technology, Process Management Technology, and an Intro to Nonwovens Tutorial. With several focused tracks, NETInc offers peer reviewed papers, expert speakers, and exclusive networking opportunities. NETInc participants can also enjoy the full PaperCon program and exhibits, Tissue360 Forum, RPTA P-T Seminar and the OpEx Reliability Workshop with their registration. Learn more about NETInc. ##SHARELINKS##

|

Edited by: A. Mimms, M.J. Kocurek, J.A. Pyatte, and E.E. Wright Liberally illustrated with more than 130 diagrams and photographs, this book includes basic formulas and diagrams to explain the structure of wood, variables affecting the quality and handling of wood chips, pulping chemistry and equipment, the pulping process, and black liquor recovery. It includes a glossary of frequently used terms. Kraft Pulping. View the Table of Contents Preview Sample Pages Product code: 0101R171 Member Price: $58.00 Non-Member Price: $87.00 ##SHARELINKS##

|

|

You still have time to register for TAPPI's Shipping, Receiving and Warehousing Workshop, April 9-10, and be a part of this dedicated group of mills, carriers, warehouses and printers as they gather to discuss and examine positive changes in the industry and innovative ways to reduce roll damage. David Schirmer, Vice President and General Manager of Hearst Enterprises will Keynote. Schirmer is responsible for paper procurement for divisions of Hearst Corp. including Hearst Magazines and Hearst Newspapers and is one of principles of Newsprint Purchasing LLC. ##SHARELINKS##

|

|

Join leading experts in the field of flexible packaging and new technology developments as they share their insights on the emerging areas of nanotechnology within packaging, April 8, at the TAPPI PLACE Flexible Packaging Symposium: New Technologies, an ICE USA pre-conference seminar at the Orange County Convention Center in Orlando, Fla., USA. This three-session event is a first-ever collaboration between two of TAPPI's premier technical divisions - PLACE (Poloymers, Laminations, Coatings and Extrusions) and the Nanotechnology Division. Sessions include Innovations in Nanocomposites, Innovations in Barrier, and Brand Launch, Shelf Appeal, and Authentication. Featuring presenters from Verso Paper, Enercon Industries, Cloeren, NOVA Chemicals, IMERYS, and more! View the preliminary program. Learn more and register. ##SHARELINKS##

|

|

Strengthen your understanding of the corrugating process, and linerboard and medium performance properties and manufacture with TAPPI's Linerboard Medium & Corrugated Box Manufacture Course, April 15-16, at the Holiday Inn in Neenah, Wis., USA. With an emphasis on helping attendees improve corrugating box performance and runnability, this popular introductory to intermediate level course is ideal for process engineers and operators in linerboard and medium manufacturing facilities and corrugating and converting plants. Instructors Michael J. Kocurek, Professor Emeritus, of Paper Science & Engineering at North Carolina State University, and Jon Porter, Senior Trainer / Process Specialist for Fosber America will address:

Register by March 15 to take advantage of the Early Bird registration discount. Join TAPPI or renew your membership for the best rates! ##SHARELINKS##

|

|

Guidelines for the Safe Operation of Steam Heated Paper Machine Dryers Guidelines for the Safe Operation of Steam Heated Paper Machine Dryers. ##SHARELINKS##

|

|

Attention Production Managers, Superintendents, Senior Operators, Regional Engineers, Quality Control, and Maintenance Technicians in Corrugated Plants and Sheet Plants - Your chance to save on registration for this course is drawing near! Register by March 16 for the best rates. Take advantage of the Early Bird Registration. The TAPPI Troubleshooting "Flexos" and "Die Cutters" Sustain Board Caliper & Improve Printing Course is scheduled for April 16-18, 2013, in Neenah, Wis., USA. Join industry veteran Dick Target, founder of On Target Consultants, as he helps attendees identify and address downtime issues and develop a better understanding of machine calibration and how to maintain proper board caliper during the converting process. Target will use an easy to understand format to help attendees improve the basic manufacturing process. Topics will include: methods to minimize caliper loss in the converting process; one-box set-up techniques; and waste reduction techniques. View the course schedule. ##SHARELINKS##

|

The highly-regarded Executive Panel on Monday, April 29, will illuminate how industry leaders are thinking and driving innovation in their companies. See who's speaking. Designed by industry professionals, PaperCon (April 27 - May 1 in Atlanta, Ga., USA) will bring together CEOs, mill managers, superintendents, scientists, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other event provides such a comprehensive program with networking opportunities and trade fair among such a distinguished group of industry leaders. ##SHARELINKS##

|

|

PaperCon Session: Insights into Effective Labor/Management Relationships Panelists: ##SHARELINKS##

|

|

PaperCon Programs Now Available Customize your learning and networking experience at PaperCon to best fit your professional needs. Bring back ideas, innovation that will help you be more effective and efficient. Papermakers program will give you everything you need to know about paper machine performance evaluations, running mill trials, and product certification. Eight peer-reviewed Coating sessions focus on scientific developments and practical tips. Highlighs include opacity enhancement with Ti02 and advancements in barrier coating. PIMA Management sessions provide excellent insight for mill managers, production managers, and executives. This year's sessions will help you develop effective labor/management relationships and show you how to motivate today's employees. The Tissue360 Forum provides a comprehensive peer-reviewed technical program unlike any other. You will learn about fiber, water, and energy savings, the latest softness and strength additives, and forming concepts. The OpEx Reliability Workshop will help you improve reliability and maintenance in your mill. Operator driven reliability, alignment, education, and mill processes will be addressed by leading reliability experts. The Young Professionals Program (YP) offers those new to the industry an unbelievable opportunity to gain basic industry knowledge and meet experienced industry leaders. ##SHARELINKS##

|

|

The Introduction to Traditional and Emerging Printing Technology Course will be co-located at the 2013 PaperCon Conference, April 27-29, 2013, in Atlanta, Ga., USA. This is an introductory course on printing methods and applications, designed for those who need to understand print quality, attend print trials, trouble shoot print problems or are generally new to printing operations. It will be taught by printing experts from TAPPI's Coating and Graphic Arts Division and is an excellent complement to the Coating Program at PaperCon. As an added bonus, the course will include a tour of Hewlett-Packard's new state-of-the art facility where production laser and inkjet presses will be demonstrated. Course attendees may also join the Coating and Graphic Arts Opening Session where printing visionary Frank Romano is giving the keynote address. Learn more and register online. ##SHARELINKS##

|

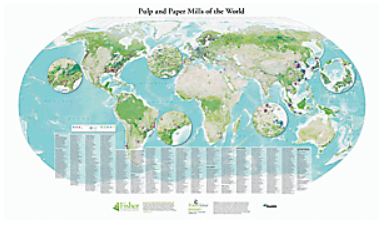

One of TAPPI's most exciting new products is the wall-sized, laminated 2013 Pulp & Paper "Mills of the World" Map. A winning combination of high quality print and paper stock along with brilliant colors makes this the perfect map to frame and hang in your office. The "Mills of the World" map features include:

Each map will be shipped in a protective tube, ready for display. ##SHARELINKS##

|

Are you ready to go further, faster in your safety career? The Certified Occupational Safety Specialist (COSS) class can take you there. The COSS Class is Unique Not only will you learn how to read and understand the OSHA 1910 and 1926 CFRs and help your company avoid OSHA citations that cost millions of dollars, but more importantly, by learning how to work safely on a job site, you can teach your company how to lower fatalities and near misses. Almost 47% of COSS graduates responding to our survey indicate that, since taking COSS, their company's injury rate and/or OSHA recordables have decreased by as much as 25% and others attest to as much as a 100% decrease! Request a Course Outline & Syllabus for more information. The class also addresses the psychology of safety, the true cost of an accident, hazard recognition, how to start up a health and safety program, behavior based safety, system safety, and much more! What Will You Receive? Upon successfully completing the class, you will obtain your national Certified Occupational Safety Specialist (COSS) designation, your OSHA 10-hr. card of completion in construction, and your OSHA 10-hr. card of completion in general industry. National Program Recognitions COSS is currently one of only 37 programs in the world recongnized and accredited by the American Petroleum Institute (API). In addition, the certifying body for construction education for colleges, universties and technical/trade schools, American Council for Construction Education (ACCE), has also recongnized our program. COSS is the only non-degree program to receive this national endorsement. Lastly, COSS has been established as a mandatory course for students in the Construction Management Program at Louisiana State University. Program Content The program consists of 40 hr. of hands on, face-to-face learning, which is delivered by an Authorized OSHA outreach trainer in both construction and general industry. Case studies and workshops are used extensively to bring learning objectives into focus. Guest speaker from areas such as OSHA and other governmental agencies are used to enhance the learning experience. Student presentations, daily quizzes, practical reviews, and a comprehensive final exam will allow you to demonstrate your competency. Prerequisites The only prerequisite for the COSS class is you must have a high school diploma or equivalent. In each class, we tend to have a mix of non-experienced, first time safety persons, as well as safety professionals who have been in the safety field for 20+ years. But, we have learned that regardless of the numbers of years of experience you have in safety, everyone leaves the COSS class with a wealth of knowledge! Visit the COSS website for FAQs, testimonials and a list of clients that have taken COSS. Register now. If you would like more information on the COSS program, contact Beth Gordon at 877-610-2677 ##SHARELINKS##

|

Leading off Session T1, Esko Uutela of RISI examines the tissue, towel, and personal hygiene products arena in North America and worldwide in term of current and projected capacities as well new and emerging trends that will shape markets into the foreseeable future. Lindsay Gervais of Pöyry Management Consulting then looks specifically at the critical fiber side of tissue and hygiene products, assessing the decline of recycled fiber quality and availability and the outlook for virgin and other fiber sources, as well as nonwovens resources that will determine the future direction of these product markets.

Leading off Session T1, Esko Uutela of RISI examines the tissue, towel, and personal hygiene products arena in North America and worldwide in term of current and projected capacities as well new and emerging trends that will shape markets into the foreseeable future. Lindsay Gervais of Pöyry Management Consulting then looks specifically at the critical fiber side of tissue and hygiene products, assessing the decline of recycled fiber quality and availability and the outlook for virgin and other fiber sources, as well as nonwovens resources that will determine the future direction of these product markets.  Gervias adds that amidst a backdrop of falling demand for printing and writing paper in mature markets, a key concern for several tissue manufacturers is the availability, quality, and cost of recovered paper. "But at what point does recycled paper become uneconomical compared with other fiber options?" she asks.

Gervias adds that amidst a backdrop of falling demand for printing and writing paper in mature markets, a key concern for several tissue manufacturers is the availability, quality, and cost of recovered paper. "But at what point does recycled paper become uneconomical compared with other fiber options?" she asks.