Over the Wire

TAPPI

Fortress Paper Ltd., Vancouver, B.C., Canada, this week reported that it will sell its wholly owned subsidiary, Dresden Papier GmbH in Germany to Glatfelter Gernsbach, Ukraine, a subsidiary of P.H. Glatfelter, York, Pa., USA, for EUR 160 million (approximately $209 million). The Dresden mill produces non-woven wallpaper base paper. Fortress Paper Ltd., Vancouver, B.C., Canada, this week reported that it will sell its wholly owned subsidiary, Dresden Papier GmbH in Germany to Glatfelter Gernsbach, Ukraine, a subsidiary of P.H. Glatfelter, York, Pa., USA, for EUR 160 million (approximately $209 million). The Dresden mill produces non-woven wallpaper base paper.

The transaction is expected to close in the second quarter of this year, but no later than June 30. It is subject to certain customary conditions, including governmental anti-trust approvals in Germany and the Ukraine. Chadwick Wasilenkoff, president and CEO of Fortress Paper, said that "the sale of the Dresden mill is an important step in Fortress Paper becoming a more focused global leader in the dissolving pulp industry. The transaction was part of our strategic plan to achieve significant liquidity to enhance future growth opportunities. We are very pleased to have been able to reach an agreement with P.H. Glatfelter and look forward to the finalization of the sale. We would also like to acknowledge the contributions of the Dresden management team over the years and wish them every success in the future." Dante C. Parrini, Chairman and CEO of Glatfelter, noted that "Glatfelter's agreement to acquire Dresden Papier demonstrates our commitment to building leading positions in niche global growth markets for specialty papers and fiber-based engineered materials. Dresden Papier has built a preeminent position in nonwoven wallpaper materials – as both the cost and quality leader because of its innovative products, proprietary manufacturing techniques, and long-standing customer relationships. "The acquisition of Dresden Papier will add another industry-leading nonwovens product line to our Composite Fibers business, and broaden our relationship with leading producers of consumer and industrial products. Despite the ongoing economic challenges in parts of Europe, we believe the global nonwoven wallpaper business will continue to grow at a compound annual growth rate of at least 10%. This acquisition will also provide additional operational leverage and growth opportunities for Glatfelter globally, particularly in large markets such as Russia and China, and other developing markets in eastern Europe and Asia." In 2012, Dresden's revenues were EUR 117 million (approximately $151 million), and earnings before Interest, Taxes, depreciation, and amortization (EBITDA) were EUR 30 million (approximately $38 million). Dresden employs some 146 people at its 60,000 metric tpy facility in Heidenau, Germany. Fortress Paper operates internationally in three distinct business segments: dissolving pulp, specialty papers, and security paper products. The company operates its dissolving pulp business at the Fortress Specialty Cellulose Mill in Canada, which is also in the process of expanding into the renewable energy generation sector with the construction of a cogeneration facility. Fortress is also seeking to expand its dissolving pulp capacity with the recent acquisition of the Fortress Global Cellulose Mill at Lebel-sur-Quévillon, Qué., Canada, which it intends to convert into a dissolving pulp mill and where it also intends to restart a cogeneration facility. The company operates its specialty papers business at the Dresden mill. Its security paper products business is at the Landqart mill in Switzerland, where it produces banknote, passport, visa and other brand protection and security papers, and at its Fortress Optical Facility in Canada, where it produces optically variable thin film. ##SHARELINKS##

|

|

UPM, Helsinki, Finland, has received the Sustainability Award 2013 for Breakthrough Innovation in Technology in Rotterdam, the Netherlands. The award which recognizes the innovation that is taking place in the development of truly sustainable and renewable fuels is presented by the World Biofuels Markets Congress & Exhibition. UPM Biofuels received the Sustainable Biofuels Award due to its success in developing an innovative production process for an advanced renewable diesel, UPM BioVerno. The award was judged by an elite panel of independent industry experts.

UPM was the winner of the Breakthrough Innovation in Technology Award because of the UPM BioVerno product characteristics corresponding to traditional fuel with the greenhouse gas emissions being reduced by up to 80%. According to Event Director Claire Poole, "the Sustainable Biofuels Awards recognize the tremendous innovation that is taking place in the development of truly sustainable and renewable fuels, and the key success factor of this novel drop-in fuel is sustainability. The feedstock is wood-based, non-food origin, with no indirect land use change. A truly sustainable achievement." Petri Kukkonen, VP of UPM Biofuels Business, noted that "during the last few years we have made progress with remarkable R&D work and important investments for developing wood-based biofuels. UPM aims to become a major player in advanced biofuels so this recognition confirms that we have managed to make significant progress in this field." UPM BioVerno is a high quality transport fuel that works well in modern vehicles and is fully compatible with existing fuel distribution systems. It has been tested for its properties, functionality, and emissions in various laboratories including VTT (Technical Research Centre of Finland) and FEV (Forschungsgesellschaft für Energietechnik und Verbrennungsmotoren GmbH) in Germany. BioVerno decreases greenhouse gas emissions significantly, the company said. The greenhouse gas reduction of approximately 80%,it added, is calculated for the whole lifecycle, taking into account all energy used in the plant and utilities used in production. BioVerno is produced from crude tall oil (CTO), a residue from the chemical pulping process. The main phases of the process are pretreatment of crude tall oil, hydrotreatment, recycle gas purification, and fractionation. Converting CTO to biofuel is an innovative way to use that residue without changing the main process, which is pulp production. This method makes additional use of an existing UPM residue, and also avoids any raw materials that could be used for food production, UPM explains. "Coming from the forest industry we benefit from our profound experience in forest biomass and extensive resources that can be used effectively for developing biofuels business and executing large scale biofuel projects," said Heikki Vappula, president of the Energy and Pulp Business Group of UPM. Currently, UPM is building a hydrogenation biorefinery on its Kaukas paper and pulp mill site in Lappeenranta, Finland. The biorefinery will produce 100,000 metric tons of renewable diesel for transport, equating to 120 million liters annually. The investment of EUR 150 million is the first industrial scale investment in this field globally. Site construction will be completed in 2014. ##SHARELINKS##

|

VTT Technical Research Centre of Finland has developed a process that enables recycled paper and cardboard to be used as a raw material for nonwovens. Hygiene and home care products, such as nappies, sanitary towels, and cleaning cloths, are among the many items that can be manufactured from the biodegradable nonwovens. The manufacturing costs of cardboard-based nonwovens are around 20% lower than for nonwovens produced from wood raw materials. The forest industry will be among those likely to benefit from new business opportunities opened up by nonwovens based on recycled paper and cardboard, VTT notes. VTT Technical Research Centre of Finland has developed a process that enables recycled paper and cardboard to be used as a raw material for nonwovens. Hygiene and home care products, such as nappies, sanitary towels, and cleaning cloths, are among the many items that can be manufactured from the biodegradable nonwovens. The manufacturing costs of cardboard-based nonwovens are around 20% lower than for nonwovens produced from wood raw materials. The forest industry will be among those likely to benefit from new business opportunities opened up by nonwovens based on recycled paper and cardboard, VTT notes.

Nonwovens are essentially consumer goods that once used will end up in a landfill site along with other community waste. In the metropolitan area alone, an estimated 10,000 metric tons of nappies and sanitary towels are disposed of each year. The principle raw material in nonwovens manufacture is biologically non-degradable polyester. Up to now, market entry for bio-based nonwovens derived from wood has stalled because of prohibitive production costs. "Now for the first time we can make use of recycled paper and cardboard as a nonwovens raw material," says Ali Harlin, research professor at VTT. "The new process means that bio-based nonwovens are now more competitive on price in comparison with plastic-based products. The manufacturing costs of cardboard-based nonwovens are around 20% lower than for nonwovens produced from wood raw materials. New business opportunities should open up fairly rapidly, since the technology required for manufacturing nonwovens from recycled materials is already in place." Every year Europe generates around 60 million tons of recycled paper, of which cardboard makes up around 40%. The demand exists for new applications and technology for exploiting recycled paper due to the EU's objective of raising the proportion of recycled paper to 70%. The method developed by VTT could extend future possibilities for re-use, particularly in the case of cardboard, which is more cost-effective as a raw material than fine paper. Cleansing the cardboard of filler material, lignin, and hemicellulose is a key part of nonwovens manufacture. VTT has matched several fiber-processing methods in the preparation of dissolving pulp to assist in obtaining pure cellulose from the recycled cardboard. The dissolving pulp produced in the research project was regenerated using VTT's patented carbamate technology, which is safer and more environmentally friendly than the traditional viscose process, VTT notes. The nonwovens were manufactured with foam forming technology that uses little water. Around 1.9 million metric tons of various types of nonwovens were manufactured in Europe in 2011. Strong growth in the global market for nonwovens is forecast to continue for the foreseeable future. Apart from hygiene, health, and cleaning products, the nonwovens have further applications in, among others, the construction industry, VTT explains. ##SHARELINKS##

|

|

The opening session at this year's OpEx Workshop at PaperCon in Atlanta, GA., USA, on April 30, features three special presentations that set the stage for the day's program exploring the latest thinking and developments in pulp and paper maintenance and reliability operations. Keynote speaker John Yolton with SKF, a highly respected paper industry reliability expert, will explore "The Continuing Journey to Asset Reliability Improvement." As Yolton notes, "with the NAM pulp and paper market contracting, only the most reliable equipment can provide a competitive advantage. Data demonstrates that there is clearly a return on investment for those ‘best' within the pool of competitors."

What do the "best" do to achieve this extra measure of competitiveness? Yolton's presentation will identify and discuss the primary issues associated with the Top 3%, e.g., the "best" and the "rest." "It might surprise you to find that ‘soft' issues play an important and vital role in the transformation and journey from the ‘rest' to the ‘best,'" Yolton says. His presentation includes a case study analysis at Daishowa-Marubeni International's 500,000 metric tpy chemical pulp mill in Canada. The opening session also includes presentations by Bill Wick of American Industrial Metrology on "A Holistic Approach to Paper Machine Alignment" and Dave Cutnaw of SKF on "Maintenance and Asset Reliability Strategies—Developing a Foundation for Success." More information about PaperCon 2013 and the OpEx Maintenance and Reliability Workshop, including registration procedures, is available online. Also available online is the 2013 OpEx Workshop program. ##SHARELINKS##

|

|

TAPPI's newest publication, Tissue360° magazine, and TAPPI tissue experts have organized a comprehensive technical forum for PaperCon 2013 in Atlanta, Ga., USA, April 28 – May 1. Covering all aspects of tissue making, the Tissue Forum includes eight information- and data-packed sessions beginning Monday afternoon and continuing through Wednesday morning of PaperCon. The program is open to all full PaperCon registrants.

The Forum's eight sessions focus on tissue and hygiene product market trends and developments, the latest chemical, fiber, water, energy, control, and converting technologies, and explore new and emerging production technologies, with a special full-session look at yankee dryer issues and concerns. All material presented at Tissue Forum has been carefully selected and reviewed by TAPPI members with extensive tissue expertise, and most of the presentations include a written paper. In Session T1 beginning after the lunch break on Monday, Esko Uutela of RISI presents a data-rich analysis of the global tissue business and trends in North America. Complementing Uutela's presentation, Lindsay Gervais of Poyry International examines the fiber side of the tissue industry with a detailed report on developing cost, quality, and sustainability issues in the global tissue arena. Session T2 on Monday afternoon covers "Chemistry Solutions for Tissue Making" with a paper by Yuping Luo of Kemira Chemicals that examines the newest generation of wet strength resins for towel grades, and a close-up look at new approaches to evaluating and enhancing tissue softness by Timothy Patterson of Ashland Water technologies.. Session T3 on Tuesday morning examines "Fiber Usage and Supply for Tissue" from four different fiber type perspectives. Fernando Pescatori Silva of Eldorado Brasil updates attendees on eucalyptus fibers. Xuejun Zou of FPInnovations provides a current overview of softwood kraft pulps for tissue making, and Medwick Byrd of North Carolina State University looks at nonwood raw materials as a possible fiber source for tissue and specialty products. The recycled fiber sourcing side is covered by Dave Anderson of SCA. Leading up to lunch, Session T4 explores "Water and Energy Strategies for Tissue," with presentations by Thomas Jenn of Kimberly-Clark on conducting tissue machine audits to reduce fiber losses and improve pulp yield, maximizing post pressure roll solids with advanced press fabric structures by Roger Banks of AstenJohnson, and engineering effective void volume in tissue production by Glen Harvey of Xerium Technologies. Session T5 begins Tuesday afternoon with a focus on Premium Tissue Manufacturing Technologies. Dennis Jewitt of Metso Paper discusses advanced technologies for structured tissue products, Roberto Zane of Voith Paper explores premium tissue technologies that are enhancing the conventional tissue world, and tissue consultant Ed Graf reports on "air dried tissue" (ADT), an alternative to TAD and similar technologies. Session T6, completing Tuesday afternoon, provides a special review and analysis of the latest tissue control techniques. Doeung Choi of Ashland Water Technologies examines the use of process simulation in structured tissue and towel making, John Feola of Cristini North America presents a roundup of the latest process control tools to boost tissue machine performance, and Richard Falcoff of Alicona Corp. looks at 3D optical micro-measurement technology to quantify surface roughness with ISO traceable Sa values. Wrapping up the Forum on Wednesday morning, Session T7 (CEU's provided) focuses directly on "Yankee Reliability," beginning with a presentation by Clive Butler of PMT on diagnosing surface chatter. Sam Archer of Nalco then looks more closely at the impact of chatter on yankee surface reliability, Jerry Vandoros of Kadant covers yankee doctor considerations for improving safety and reliability, and John Yolton of SKF explores reliability best practices in the global tissue industry. Session T8 on "Converting Efficiencies" features presentations by John Cork of Ibis International on process air filtration for tissue converting and Karl Hilden of Papertech on solving tissue production and converting problems using event capturing camera systems. Completing the Forum's final session on Wednesday morning, Futura analyzes key factors for enhanced converting performance. ##SHARELINKS##

|

|

TAPPI's 2013 Tissue Properties and Manufacturing Course, to be held in conjunction with PaperCon 2013, covers the fundamentals of manufacturing and provides an excellent overview of this dynamic market segment. The two-day course will be held on April 27-28, 2013 in Atlanta, Ga., USA, and precedes PaperCon and the Tissue360° Forum.

"Tissue manufacturing is technically innovative and rapidly growing and the Tissue Course provides an excellent overview of manufacturing operations, equipment, and tissue sheet properties," notes Larry N. Montague, TAPPI president and CEO. "Course participants will be able to also take advantage of the Tissue360° Forum and all of the networking opportunities available during PaperCon." This course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties, and the effect of manufacturing processes on them. It provides an excellent educational compliment to the Tissue360° Forum sessions. Attendees will learn about a wide range of key topics including: tissue properties and tests; stock prep and refining; chemicals (wet end and yankee); wet end operations; TAD and yankee drying; creping; calendaring; and converting. A no-charge webinar featuring some of the course content will be held on March 6, "Tissue Manufacturing for Softness." More information about this course is available online. The Tissue360° Forum and PaperCon 2013 feature the industry's largest technical program in addition to a number of special events, seminars, and tracks on a wide range of topics and industry segments, numerous networking opportunities, keynote presentations, and a trade show exhibit. ##SHARELINKS##

|

|

Wood fiber prices trended downward in the local currencies in many of the key pulp-producing countries of the world in the fourth quarter of 2012. However, as a result of the weakening U.S. dollar, wood fiber prices actually increased in U.S. dollar terms in a number of countries and the Softwood Wood Fiber Price Index (SFPI) was up slightly (+0.1%) in the fourth quarter to $100.13 per oven dry metric ton (ODMT). The biggest increases from the third quarter to the fourth quarter occurred in Eastern Canada, Finland, France, and New Zealand, according to the Wood Resource Quarterly, Seattle, Wash., USA.

Price declines in the local currencies were mainly the result of an increased supply of softwood fiber in regions with extensive lumber production. In the U.S. Northwest, chip prices fell as much as 27% during 2012 and pulp mills in the region had some of the lowest softwood fiber costs in the world in the fourth quarter. Additional volumes of residual chips from increased lumber production, reductions in pulp production and pulp mill outages, and large supplies of pulp logs were all factors that contributed to the dramatic turnaround in fiber costs during 2012. A similar trend was seen in Western Canada, where prices in the fourth quarter of 2012 were down 22% from late 2011, reaching their lowest levels in three years. Hardwood fiber price movements were mixed, with hardwood pulp log prices generally trending downward in many of the key hardwood pulp-producing regions in both local currencies and in U.S. dollar terms. This resulted in a decline in the Hardwood Wood Fiber Price Index (HFPI) to $104.80/ODMT in the fourth quarter. This was down 1.5% from the previous quarter and 7.8% from the fourth quarter of 2011. The biggest decline in hardwood fiber prices occurred in Brazil where Eucalyptus log prices have fallen continuously for more than a year from early 2011, when they were at their all-time highs. In the fourth quarter of 2012, prices in U.S. dollar terms were back down to the same levels as where they were in early 2009. Few regions in the world currently have lower hardwood costs than Brazil. ##SHARELINKS##

|

|

Global attention towards the paper industry of Russia has increased in recent years, according to a new report being offered by Research and Markets, Dublin, Ireland, titled Russia Paper Market Forecast & Opportunities, 2017. Several factors have helped the paper industry in Russia gain a competitive advantage in the recent years.

About 20% of the world's total forest land cover is present in Russia only, which ensures the continuous supply of forest fiber to the paper industry. Some of the growth drivers for the paper industry in Russia are rising GDP, increasing industrial output, high export, government fund infusions, high disposable income, and urbanization. Russia's Ilim Group, which has a joint venture with International Paper (Memphis, Tenn., USA) is a market leader in terms of paper production in Russia. The players present in the Russian paper market are set to increase their production capacity in coming years to take full advantage of available abundant raw materials in Russia. According to the new report, revenues generated by the paper industry in Russia are expected to grow at a healthy rate, much higher than in the previous three years, reaching $6.4 billion by 2017. The share of the northern region of Russia in the total production of paper and paperboard was more than 25% in 2011, which was the highest of all regions. This is mainly due to the fact that the northern region is heavily forested, offering huge wood fiber volumes to the paper industry. ##SHARELINKS##

|

Andritz, Graz, Germany, has delivered the world's largest, high-precision steel yankee dryer to the Zellstoff Pöls AG mill in Austria, for installation on Europe's largest kraft paper machine. The PrimeDry steel yankee (6.7 meter dia., weight 150 metric tons) was manufactured in two parts for transport purposes. The yankee is made entirely of steel, providing higher performance and enhanced safety compared with a cast iron yankee. It is currently being assembled and welded, and will be lifted into the machine room this June with a 600 metric ton crane. Andritz, Graz, Germany, has delivered the world's largest, high-precision steel yankee dryer to the Zellstoff Pöls AG mill in Austria, for installation on Europe's largest kraft paper machine. The PrimeDry steel yankee (6.7 meter dia., weight 150 metric tons) was manufactured in two parts for transport purposes. The yankee is made entirely of steel, providing higher performance and enhanced safety compared with a cast iron yankee. It is currently being assembled and welded, and will be lifted into the machine room this June with a 600 metric ton crane.

Andritz is supplying a PrimeLine paper machine to Zellstoff Pöls for the production of specialty paper. The new 5.4 meter wide machine, with a capacity of 80,000 metric tpy and a design speed of up to 1,000 meters per minute, will produce very high-strength paper grades used for shopping bags, high-grade medical packaging, and food packaging. Andritz's scope of supply includes the stock preparation plant, an approach flow system, the complete fourdrinier paper machine, a calender, and the automation systems. Startup is scheduled for the end of this year. With this investment, Zellstoff Pöls—the largest manufacturer of high-quality, ECF bleached kraft pulp using softwoods from central and southeast Europe—is extending its existing paper production capacity. The total investment amounts to EUR 115 million. ##SHARELINKS##

|

C&S Paper, China, has brought two new 28,000 metric tpy tissue machines online at its mill in Jiangmen city, Guangdong province. The identical units, supplied by Toscotec, Italy, have a wire width of 3.6 meters and a design speed of 1,600 meters per minute. C&S Paper, China, has brought two new 28,000 metric tpy tissue machines online at its mill in Jiangmen city, Guangdong province. The identical units, supplied by Toscotec, Italy, have a wire width of 3.6 meters and a design speed of 1,600 meters per minute.

C&S Paper has the construction of four more tissue machines well underway, with startup planned for later this year. These new machines will boost the company's total tissue capacity to around 520,000 metric tpy. Two machines with a combined capacity of around 59,000 metric tpy will begin production in the second half of 2013 at the C&S Paper site in Chengdu city, Sichuan province. One will have a trim width of 3.55 meters, and a design speed of 1,650 meters per minute. It will produce tissue at a rate of 32,000 metric tpy. The other one will have a trim width of 2.85 meters and a design speed of 1,700 meters per minute. Its capacity will be around 27,000 metric tpy. ##SHARELINKS##

|

|

CMPC Celulose Riograndense, Brazil, has completed a commercial agreement with Minerals Technologies Inc. (MTI), Bethlehem, Pa., USA, to provide Fulfill E-325 to its paper mill in Guaiba, Brazil. This is Minerals Technologies' first such agreement in South America for the new, high-filler technology.

MTI now has 13 agreements with paper mills that have adopted the Fulfill E-325 technology introduced in late 2010. MTI notes that the FulFill brand offers papermakers a variety of efficient, flexible solutions that allow papermakers to increase loading levels of precipitated calcium carbonate (PCC), which replaces higher cost pulp, and increases PCC usage. "We are very pleased that this premier paper company, with which we have been supplying PCC at Guaiba since 2007, will adopt our new FulFill technology. FulFill will provide CMPC a competitive advantage and allow them to continue producing quality paper but at a lower cost," said Joseph C. Muscari, executive chairman of Minerals Technologies. "We now have commercial agreements with papermakers in Asia, Europe, South Africa, and North and South America, which validates the revitalization of our research and development pipeline and our commitment to advance our technology leadership throughout our global satellite network." CMPC Celulose Riograndense is one of the largest regional producers of bleached pulp using short eucalyptus fiber. The company's industrial unit, located in Guaíba, in the metropolitan region of Porto Alegre, runs a state-of-the-art cellulose pulp mill, with modern resources for environmental protection. It has an installed capacity of 450,000 metric tpy of pulp, aimed at the manufacture of personal hygiene paper and specialty paper. Part of the pulp production is directed to the on-site paper machine to produce 60,000 metric tpy of printing and writing paper, mainly sold in the domestic market. CMPC Celulose Riograndense is a subsidiary of Chilean-based Empresas CMPC S.A. ##SHARELINKS##

|

|

Forestal y Papelera Concepción S.A., Chile, has ordered a Metso (Finland) Advantage NTT 200 tissue production line for its mill close to Concepción. A packaging board producer, Forestal y Papelera Concepción is entering the tissue business and is preparing to start up its first tissue production line.

The new line will be the world's second tissue line based on Metso's Advantage NTT concept and the first with a 5.5-meter paper width. It will have a capacity of 70,000 metric tpy of bathroom tissue, napkin, and towel grades, and is scheduled to start up at the end of 2014. The value of the order has not been disclosed. The Advantage NTT technology enables premium bulk and softness properties at the same time as it provides energy savings compared with conventional or other structured tissue grades. The Advantage NTT concept is a flexible production tool and quickly enables change between production of conventional and premium tissue and towel products. It also features very high production capacity. "Collaborating with top level companies who can supply equipment that ensures quality and support of great expertise has always been important to us. When we now are entering the tissue business, after operating in the newsprint and packaging paper segments, we are aiming for the top level products. Therefore Metso's Advantage NTT tissue line was the best choice for us," says Guillermo Swett, CEO, Forestal y Papelera Concepción. Metso's scope of supply will include a complete Advantage NTT 200 tissue machine with a width of 5.5 meters, equipped with an OptiFlo II TIS headbox, a Metso cast iron yankee cylinder, an Advantage AirCap yankee hood, and an Advantage SoftReel reel. The tissue line will also be equipped with an Advantage WetDust dust management system, sheet control, tail threading equipment, and complete stock preparation systems. The line will be fully automated and optimized to enhance final product quality. Forestal y Papelera Concepción S.A. (FPC), an innovative company highly experienced in the manufacture of paper, was founded in 1995. Since 2009 it is mainly producing recycled fiber-based packaging paper. The company's new tissue production line and converting facilities will deliver jumbo rolls and converted tissue products for the South American and U.S. market. ##SHARELINKS##

|

|

Hayat Kimya A.S., Turkey, has ordered two complete tissue production lines from Metso, Finland. Each line will include an Advantage DCT 200 TS tissue machine, and they will be installed at the company's new mill sites near the city of Alabuga, Tatarstan, in Russia, and in the city of Mersin in southern Turkey. Startup of the tissue machine to be installed in Russia is planned for the second half of 2014, and the second tissue machine will start up in Turkey at the end of 2015. The value of the order has not been disclosed.

The order follows the successful startups of two similar tissue lines supplied by Metso in 2010 and 2011.The tissue machine located at the mill in Yeniköy near the city of Izmit, Turkey, holds the world record in speed for tissue machines at 2,210 meters per minute. "Metso has been a reliable and trustworthy partner for our previous installations and we are pleased to continue our good cooperation also in this new project," says Lütfi Aydin, director, Paper Group, Hayat Kimya. Metso's scope of delivery includes two complete tissue production lines featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. Each machine will be equipped with an OptiFlo headbox, a Metso yankee cylinder, an Advantage ViscoNip press, an Advantage AirCap hood prepared for co-generation, an Advantage WetDust dust system, an Advantage Run sheet transfer system, and an Advantage SoftReel L reel. The stock preparation lines will consist of OptiSlush pulpers, OptiFiner conical refiners, and OptiScreen machine screens. Furthermore, the delivery will include an extensive automation package with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery. Both tissue machines will have a width of 5.6 meters and a design speed of 2,200 meters per minute. The new lines will have a design capacity of 70,000 metric tpy of high-quality facial, toilet, and towel grades. The raw material for the new lines will be virgin fiber. The production lines are optimized to save energy and to enhance final product quality. Hayat Kimya A.S. is part of the Hayat Group, which primarily operates in the chemicals, hygienic products, paper, and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 140,000 metric tpy and a converting capacity of 100,000 metric tpy. Through the new investment and ongoing projects, the total production capacity of Hayat Kimya will reach 350,000 metric tpy. ##SHARELINKS##

|

|

Holmen Paper, Stockholm, Sweden, this week reported that it plans to cease production on PM 51 at its Braviken Paper Mill outside of Norrköping, Sweden, during the third quarter of this year, reducing the mill's production of newsprint by 200,000 metric tpy. At the same time, the mill's staff will be cut by 180 people.

"We're forced to shut down parts of our newsprint production," said Henrik Sjölund, head of Holmen Paper. "Falling demand, pressure on prices, excessively high costs of raw materials, and last but not least, the strong Swedish krona, makes this measure inevitable. It's extremely regrettable that it has to affect so many of our employees." The restructuring process is a further step in the strategy of concentrating Holmen Paper's Swedish operations on specialty paper, Holmen notes. "This spring, we'll be introducing book paper from Braviken while further refining the specialty products that are already being produced today," Sjölund adds. "The measures are part of our change strategy in which we're developing unique specialty paper that makes the production processes of our customers more cost efficient." Following the restructuring program, Braviken Paper Mill is estimated to have 360 employees and two paper machines with an annual capacity of just under 600 000 metric tons of printing paper. When the changes currently underway at Holmen Paper have been completed, it is estimated that the Swedish units will be able to produce 1,150,000 metric tpy of printing paper, of which 75% will be specialty paper, a portion that is expected to grow further. Production is 90% based on virgin fiber. At the mill in Madrid, slightly more than 300,000 metric tons of newsprint is produced, based on recovered paper and recovered water. The combined workforce in the business area is approximately 1,000 employees. Operating profit for the first quarter is expected to be affected by an impairment loss on non-current assets (SEK 100 million) and a provision for restructuring costs (SEK 40 million). ##SHARELINKS##

|

|

The Koryazhma Mill of OJSC Ilim Group, St. Petersburg, Russia, reports that it is investing more than $22 million to rebuild recovery boiler No. 6 at the thermal power station. The project goal is to increase the efficiency and improve environmental performance of the recovery operations.

Ilim Group's business assets, located in the Leningrad, Arkhangelsk, and Irkutsk Oblasts, are the largest mills in the Russian forest products industry, accounting for more than 65% of the total pulp production in Russia and more than 21% of the Russian board production. The total annual pulp and paper production volume of the company is more than 2.6 million metric tons. International Paper Co., Memphis, Tenn., USA, is a strategic partner of Ilim Group, owning 50% of its shares. Ilim Group employs 19,000 people. ##SHARELINKS##

|

|

NewPage Corp., Miamisburg, Ohio, USA, this week announced the launch of WherePaperWorks.com, a new website specifically designed as a comprehensive and easy-to-use online resource for converters, brand owners, and end users of specialty papers. The new website features content on specialty paper applications, segments, and innovation, including a downloadable calendar of industry events.

Created with the user experience firmly in mind, the website has been designed using the latest technology so that it is compatible with today's browsers and mobile devices. The site also includes news and social media content feeds, as well as a wide array of product information to help customers understand the complete range of specialty paper solutions at NewPage. NewPage is a producer of printing and specialty papers in North America, with $3.5 billion in net sales in 2011. The company owns paper mills in Kentucky, Maine, Maryland, Michigan, Minnesota, and Wisconsin, with a total annual production capacity of some 3.5 million tons of paper. ##SHARELINKS##

|

|

Norske Skog, Norway, this week said that it will temporarily idle one newsprint machine (PM 2) at its Norske Skog Skogn mill in Norway, beginning June 1. PM 2 has a production capacity of 130,000 metric tpy. Skogn has an annual capacity of 550,000 metric tons.

"The temporary closure of capacity at the Skogn mill is required, both to create a better balance between demand and supply for newsprint in Europe, and to avoid unprofitable production at Skogn. Despite years of great efforts by the staff to reduce costs, the decision is unfortunately unavoidable due to factors including the strong Norwegian krone," said Sven Ombudstvedt, president and CEO of Norske Skog. The one machine still in operation at Norske Skog Tasman (New Zealand) will reduce production by removing 15,000 metric tons from the market, as a direct consequence of the energy price development in New Zealand, the company noted. ##SHARELINKS##

|

Södra, Sweden, reports that it is ceasing efforts to sell its Södra Cell Tofte mill in Sweden due to bids it has received being too low. This decision will now be reported to the county. If no solution is found during the month-long qualifying period, the company plans to stop production on May 1. Södra, Sweden, reports that it is ceasing efforts to sell its Södra Cell Tofte mill in Sweden due to bids it has received being too low. This decision will now be reported to the county. If no solution is found during the month-long qualifying period, the company plans to stop production on May 1.

"We have been working to find a buyer for the Tofte mill for almost six months now, and we have been in contact with a large number of potential buyers during that time. However, we are forced to conclude that we have received a limited number of bids, and that the levels of the bids made are too low to make it worthwhile continuing with the sale," said Gunilla Saltin, acting CEO of Södra and president of Södra Cell. The company explains that it has been attempting for some time now to achieve profitability at Södra Cell Tofte, but it has not been possible to turn the tide despite a number of measures being implemented. This was why a process began in October 2012 to find a buyer. This past February, Södra announced its intention to liquidate its holding in Södra Cell Tofte and reported that a sale process had begun. Contact was made with a large number of potential buyers all over the world, but no sufficient bids led the company to cancel the sale process. The Tofte mill was purchased by Södra in 2000. Its production capacity totals 400,000 metric tpy of chemical paper pulp. It employs about 300 people. ##SHARELINKS##

|

|

Syktyvkar Tissue Group, Russia, has placed a repeat order with Metso, Finland, for a new tissue machine to be installed at the company's new site in Semibratovo, located some 220 km from Moscow. Start up of the machine is scheduled for mid-2014. The value of the order was not disclosed.

The order follows the previous Metso installation of an Advantage DCT 100 tissue machine in 2007 and a major tissue machine rebuild during 2012. "Metso's delivery will include a complete high-speed tissue production line featuring an Advantage DCT 100 HS tissue machine equipped with an OptiFlo headbox, a Metso cast iron yankee cylinder, and an Advantage AirCap yankee hood. Metso will also supply stock preparation equipment, including an OptiFiner conical refiner, OptiScreen cleaning and screening technology, and converting broke equipment. In addition, Metso's scope of supply will include an electrification package, pumps, agitators, instruments, a vacuum system, and white water handling. The delivery will include basic and detail engineering for the new tissue machine and services for installation and startup of the machine. Furthermore, Metso will supply Metso DNA automation for process, machine, and drive controls, and Metso IQ quality controls. The new line will have a width of 2.7 meters and an operating speed of 2,000 meters per minute, and it will add another 30,000 metric tpy of bathroom tissue, napkin, and towel grades to the company's existing production. Today Syktyvkar Tissue Group is one of the best known companies on the Russian market for tissue products with a market share of around 10%. The company employs 385 people and produces some 45,000 metric tpy of tissue. The company's headquarters and existing production facilities are located in Syktyvkar, capital of the republic of Komi in the northwestern part of Russia. ##SHARELINKS##

|

|

The Mayr-Melnhof Group, Austria, has started up its new packaging plant in Poland. According to EUWID Pulp and Paper, Germany, test runs at the site in Bydgoszcz started earlier this month and will reach full capacity in the course of the month.

The plant produces corrugated folding cartons and is located near Mayr-Melnhof's existing plant in the same town. The company's overall capacity in Bydgoszcz will be about a third higher due to startup of the new machine. EUWID also reported that, according to a statement by the city of Bydgoszcz, Mayr-Melnhof has invested more than PLN 50 million (EUR 12 million) to build the plant, which is the company's third plant in Poland. Mayr-Melnhof reportedly plans to hire 100 people.

##SHARELINKS##

|

|

Mondi, South Africa, has ordered environmental upgrades from Andritz (Graz, Austria) for its mills in Slovakia, Sweden, and the Czech Republic. The orders are part of Mondi's program to increase energy efficiency and environmental protection.

For Mondi SCP, Ružomberok, Slovakia, Andritz will deliver a High Energy Recovery Boiler (HERB). In terms of its power-to-heat ratio, the new boiler will be one of the most efficient recovery boilers in the world. It will replace an existing boiler, increase the mill's electricity production significantly, provide conditions for operation with a minimized amount of fossil fuels, and will also enable an increase of pulp production. The delivery also includes an evaporation plant retrofit. The evaporator will represent the latest technology including seven-effect heat economy, enhanced internal condensate purification, and 85% black liquor concentration. Startup of the boiler and the rebuilt evaporation plant is scheduled for the end of 2014. At Mondi's Dynäs mill in Väja, Sweden, two existing lime kilns will be replaced by a new Andritz lime kiln. Based on its LimeFlash technology, operating costs will be reduced due to lower fuel consumption. Startup is planned for the fourth quarter of 2013. For Mondi's Štětí, Czech Republic, mill, Andritz will build a packaging paper machine (PM 7) to produce various amountw of bleached kraft grades. PM 7 will start up in the latter part of 2014. In addition, the mill's PM 5 will receive an upgrade of its dryer section this October. ##SHARELINKS##

|

Cortec, St. Paul, Minn., USA, has introduced its Bio Wrap® Creped premium corrosion inhibiting paper. The paper employs Cortec's Vapor phase Corrosion Inhibiting (VpCI®) technology for protecting metals in an enclosed package. Cortec, St. Paul, Minn., USA, has introduced its Bio Wrap® Creped premium corrosion inhibiting paper. The paper employs Cortec's Vapor phase Corrosion Inhibiting (VpCI®) technology for protecting metals in an enclosed package.

The "environmentally safe," non-toxic, biodegradable crepe paper combines multi-metal corrosion protection with the benefits of crepe paper. As a result of the creping, the tensile strength is increased and a high degree of pliancy is achieved, Cortec notes. Bio Wrap Creped paper provides cushioning and surface protection for wrapped parts and a "pooling" effect for oiled parts. It is cost efficient and environmentally more advantageous than bubble films, packaging peanuts and other cushioning materials, the company says. The paper used in Bio Wrap does not contain any nitrites, phosphates, or silicates. It is effective against the most aggressive environments including humidity, SO2, H2S, and galvanic corrosion from dissimilar metals. It eliminates the need of a variety of papers for all of the different types of metals and alloys, the company adds. Bio Wrap is fully recyclable and repulpable. It protects products for storage and shipment in a variety of ways—end closures for shipping tubes, insert strips for recessed areas in large packages, and as sheet liners or separators between products. Typical applications include metal producing, metal forging, die casting, metalworking, finished products, electrical and electronic components, and controls. ##SHARELINKS##

|

|

Gorham Paper and Tissue, Gorham, N.H., USA, has launched four category-specific paper brands: Optix™ for packaging, Helix™ for engineered, Vertix™ for converting, and Iconix™ for printing. The portfolio features close to 30 customized specialty papers available with options in weight, color, furnish, and functional properties.

"The new brands reinforce our strategy to direct our product development expertise and manufacturing flexibility to more challenging technical markets. They communicate our depth of capability, segment our offering, and simplify our extensive lineup," said Brian McAlary, VP of sales and marketing." The Gorham specialty papers include:

Gorham specialty papers are available in a basis weight range of 18 lb.–143 lb. and with furnish options (white, natural, and a variety of colors), recycled content up to 100%, and chain of custody certification to SFI, FSC, and PEFC standards. ##SHARELINKS##

|

|

Tembec, Montreal, Que., Canada, this week officially launched its Kallima Coated Cover C2S 14 pt - the latest extension of its line of bleached paperboard products. This new product release, Tembec notes, stems from its continuous investment in research and development operations.

Tembec point out that with the new 14 pt caliper coated two-side cover grade, printers can benefit from savings of up to 20% due to Kallima's basis weight advantage achieved through its unique high-bulk, low-density construction. Kallima's on-press reliability, visual performance, and savings potential make it ideal for business cards, post cards, direct mail, POP displays, advertising collateral, and pocket folders. Kallima Coated Cover C2S 14 pt is available in rolls and sheets (skids only), and is fully compatible with post press production effects such as die cutting, UV and aqueous coating, folding, scoring, embossing, debossing, and foil stamping. It is FSC-certified and available with 10% recycled content upon request. Tembec is currently taking pre-orders for deliveries in late April. Tembec is a producer of lumber, pulp, paper, and specialty cellulose. Its principal operations are in Canada and France. The company has some 3,700 employees and annual sales of approximately $2 billion. ##SHARELINKS##

|

|

Ziegler Paper Mill, Grellingen, Switzerland, a producer of high quality, woodfree fine papers and specialty papers, this week introduced two new printing and writing paper products. Z-Advance (60-200 gsm) is an easy-to-use, high-speed paper that is treated online and specially developed for drop-on-demand inkjet applications (pigmented ink systems). First-rate color density and low shine-through make the paper an ideal choice, particularly in the lower weight range, the company notes. Z-Advance is particularly suitable for trans-promotional, transactional printing, and direct mail applications with pigmented inks. Printed matter is immediately ready for further processing after printing, and has excellent smear and water resistance, Ziegler adds.

Z-Advance unique (80/90 gsm and 120/135 gsm) is a high-speed inkjet paper that is coated online and specially developed for drop-on-demand inkjet applications (pigmented ink systems). It is hallmarked by its low ink consumption, which is controlled by a new coating concept that fixes the ink directly to the surface of the paper. First-rate color density, low shine-through, excellent resolution, and very good ink drying results make the paper an ideal choice for demanding applications, Ziegler points out. Ziegler Paper Mill's PM 3 (about 72,000 metric tpy capacity) has a wire width of 331 cm. It produces papers with weight ranges from 40 to 400 gsm. ##SHARELINKS##

|

|

The Newark Group, Cranford, N.J., USA, has announced a 4% price increase on all sheets, cut-to-size panels, loose leaf panels, spines, and all specialty products manufactured by Newark Custom Paperboard (formerly BCI). The increase becomes effective with orders shipped on or after April 15.

"While continuous improvement in our processes is an ongoing effort, escalating external costs make this price change necessary," said Paul Spitale, VP of Sales, Newark Converting Divisions. ##SHARELINKS##

|

|

Minerals Technologies Inc., Bethlehem, Pa., USA, has elected Robert S. Wetherbee president and CEO, and Joseph C. Muscari, who has served as chairman and CEO since 2007, will remain with the company as executive chairman. Wetherbee, who was president of ATI Tungsten Materials in Nashville, Tenn., a business unit of Allegheny Technologies, joined the company on March 11.

"I am very pleased that we have someone of Bob Wetherbee's caliber join MTI as CEO," said Muscari. "He is an accomplished global business leader with more than 30 years of experience in general management, finance, operations, and marketing. I am confident that Minerals Technologies will continue on its high-performance track with Bob as CEO and I look forward to working with him." Before joining Allegheny Technologies, Wetherbee spent 29 years at Alcoa in positions of increasing responsibility, including president of two business units with more than $2 billion in revenues. He served as VP, market strategy for Alcoa from 2006 through 2010, where he focused on new product development and global market positioning for Alcoa's downstream value-added products. Before that, he was president of Alcoa Rigid Packaging, a $2.4 billion business with 2,250 people from 2004 to 2006. This business unit supplied global customers in the beverage and food can industry. From 2003 through 2004, Wetherbee served as president, Alcoa Mill Products, which had $2 billion in revenues and 3,600 people at nine locations that supplied customers in the aerospace, ground transportation, and building and construction industries. Wetherbee joined Alcoa in 1981 in finance, where he held various positions until 1991. Between 1991 and 2003, he served in roles of increasing responsibility in general management, including GM of the Americas' Closure business, CEO/president of eBusiness and Metalspectrum, and business development manager, Europe. Wetherbee holds a B.S. degree in Industrial Administration and Accounting from Iowa State University in Ames, Iowa. He served as co-chair of the Blue Green Alliance Corporate Advisory Council, a national partnership between labor unions and environmental organizations, and has been active in numerous community organizations throughout his career. ##SHARELINKS##

|

|

The TAPPI NET Division 2013 Innovations in Nonwovens Award, sponsored by the Herty Advanced Materials Development Center, is being awarded to Jaime Braverman of Kimberly-Clark Corporation in recognition of his innovation, dedication, initiative, and leadership. To be presented during the TAPPI Innovative Nonwovens Conference (NETInc), co-located with PaperCon 2013, April 29 - May 1, this award recognizes individuals at companies/universities/organizations who are moving the nonwovens industry forward and changing the world we live in through innovation. Jaime Braverman is currently program manager R&D within Global Nonwovens at Kimberly-Clark and is responsible for managing the development and commercialization of specialized nonwoven materials used in hygienic consumer products globally. He has more than 20 years of experience in research, development, manufacturing, and commercialization of hygienic products based on innovating nonwoven materials in North America, Latin America, and global markets. The Innovative Nonwovens Conference (NETInc), where the 2013 Innovation in Nonwovens Award will be presented, is the only technical conference developed by engineers and technologists to help industry professionals understand the innovation behind the science and how it impacts the market. ##SHARELINKS##

|

TAPPI welcomes our newest members - Eric Hobbs and Todd Palmer. Both Eric and Todd are Partners with Michael Best & Friedrich LLP. Founded in 1848 (that's not a typo!), Michael Best & Friedrich is 220 attorneys strong and has ties to the pulp and paper Industry. To learn more about Michael Best & Friedrich visit their website at www.michaelbest.com or contact Eric at eehobbs@michaelbest.com or Todd at tepalmer@michaelbest.com. ##SHARELINKS##

|

|

The Pulp and Paper Manufacturers Association (PPMA) has launched its first-ever Best Place to Work Award. The award is open to all companies in the forest products industry and will look not only at corporate life but also look at how employees feel about their work environments. In conjunction with Majority Opinion Research Group, PPMA has started taking nominations for this award and will continue to accept nominations through July 1, 2013. "This award is an exciting opportunity for PPMA to honor great companies. As an association that serves HR professionals, we know the value of the making your company a great place to work," said PPMA President Joe Thibaudeau, employee relations manager - Procter & Gamble - Green Bay, Wis., USA. The award will be presented to the winner at the annual PPMA conference on October 23-25, 2013, in Milwaukee, Wis., USA. The winner will have the chance to speak with conference attendees about what makes his or her company the "Best Place to Work." PPMA is a nonprofit association built around a community comprised of executives, managers, and human resource professionals from the pulp and paper industry. For its members, PPMA serves as a primary source of information on labor settlements and current human resource issues, governmenta,l and related operational issues. To nominate your company for the Best Place to Work Award, use the online form. ##SHARELINKS##

|

|

The Pulp and Paper Safety Association (PPSA) will host its 70th Annual Safety and Health Conference - "The Human Element of Safety," June 9-12, 2013 in Williamsburg, Va., USA. At the conference, presenters will address how human behavior will proactively help prevent, detect, and control events before they occur. Professionals from across the country know the importance of safety and attendees will hear from 18 speakers who will show the impact of addressing the human impact on safety. The conference will feature updates from OSHA, member company case studies, and PPSA's popular legal update. Among the confirmed speakers are representatives from MeadWestvaco, Weyerhaeuser Co., Domtar, Safe Start, International Paper, REM Safety Consulting, Michael Best & Friedrich Law Firm, Training Logic, Change Management Consulting, and BushCo. PPSA is a non-profit, non-political, international organization, devoted to the countinuous improvement of safety throughout all aspects of the paper industry. From forest products to paper mills, to converting plants, to recycle collections centers, our membership is grouped by category to ensure a fair and appropriate basis for comparison. Registration is currently open for this event. More information is available online. ##SHARELINKS##

|

|

Please send books to: ##SHARELINKS##

|

|

Fact: the current economy has affected many schools' endowment funds, resulting in decreased support of student scholarships. But here's the good news" TAPPI has scholarships to offer. You have a chance to apply for some green (funds to pay tuition, etc.) to fund a satisfying green career. The scholarships are available for graduate and undergraduate students with an interest in the pulp, paper, converting, and packaging industries. There are two general types of scholarships: William L. Cullison Memorial Scholarship for details. What this message means to you:

##SHARELINKS##

|

TAPPI member Nick Triantafillopoulos, Ph.D., says he believes strongly in one's "ethical obligation to give back through service," especially to an organization that has played a pivotal role in your career. That's why he has been an active member since 1981 when he was just beginning his pulp and paper career path and eager to make a difference in the industry he loves. "Membership has meant an opportunity to develop not only technical and leadership skills, but also a network of technical experts and friends." This tight-knit relationship with his profession and TAPPI is still going strong. "Part of engaging in TAPPI is the opportunity to play a leadership role in volunteerism," he said. Besides teaching training courses, organizing symposia, progressing through committee chairs, writing a division newsletter, and editing articles for TAPPI Journal, Nick says helping to execute change in the volunteer programs taught him the inherent challenges and satisfaction of seeing a new, morphed organization created. Find out more by reading this month's Member Spotlight. Spotlight participants are recommended by fellow members and staff. If you would like to nominate a member just send his or her name (or names) to MemberSpotlight@tappi.org. We will forward a Spotlight Questionnaire to fill out and return. We look forward to seeing you in the Spotlight! ##SHARELINKS##

|

|

Nominations for the major TAPPI 2014 awards are due by August 1, 2013. The awards that may be presented in the upcoming year are: Gunnar Nicholson Gold Medal Award - The Association's highest technical honor may be presented annually to recognize an individual or individuals for preeminent scientific and engineering achievements of proven commercial benefit to the world's pulp, paper, board, and forest products industries and the other industries that TAPPI serves. Herman L. Joachim Distinguished Service Award - The Association's highest award for service may be presented annually to recognize leadership and service that have significantly and demonstrably contributed to the advancement of the Association. Paul W. Magnabosco Outstanding Local Section Member Award - The highest honor for Local Sections may be presented annually to recognize an individual for outstanding leadership and exceptional service to one or more Local Sections, which have resulted in significant and demonstrable benefits to the Local Section members. TAPPI Fellow - TAPPI Fellows are individuals who have been members of TAPPI for not less than 10 years prior to the nomination, and who have contributed meritorious service to the Association and/or the paper and related industries. Retiring members of the TAPPI Board of Directors become Fellows automatically at the end of their term. The TAPPI Awards and Honors page has links to these awards that will show the qualifications required and links to the nomination forms that must be completed. You may submit all nomination forms by email to standards@tappi.org, or you may fax them to the attention of the awards department at +1-770-446-6947, or send them by mail to TAPPI, Awards Department, 15 Technology Parkway South, Peachtree Corners, GA 30092, USA. ##SHARELINKS##

|

|

The TAPPI - PPSA Safety Management Leadership course is designed to build leadership commitment and engagement for a culture of safety excellence. This partnership with the Pulp & Paper Safety Association brings you the best safety practices in the industry. The Safety Management Leadership Course will be held April 10-11, 2013, at the TAPPI Training Facility in Peachtree Corners, near Atlanta, Ga., USA. This course delivers curriculum to help you learn the fundamentals of record-keeping, incident investigation, risk management, cultivating a safety culture, managing change safely, and measuring performance. Take a look at the expert panel of instructors. The course is designed for anyone that is involved in workplace safety. Course registration is limited to only 20 participants, so please register today at the course website. TAPPI and PPSA members save, and early registration discounts are available. ##SHARELINKS##

|

|

Establishing and Maintaining Effective Labor/Management Committees Thursday, March 28, 2013 12:00 - 1:00 pm EST This is a free webinar, but you must register to attend. Labor management committees (L/M committees) foster better communication, understanding, and enhance labor-management partnerships to enable the management and labor to collaborate on workplace problems in a timely manner. But how do you establish and maintain one? Attend this one-hour webinar and learn how to build consensus, establish the committe, and effectively train members. This webinar is a preview of "Effective Labor/Management Relationships," sponsored by PIMA and PPMA; part of the PIMA Management Program of PaperCon taking place April 28 - May 1 in Atlanta, Ga., USA. Learn more about this webinar. Learn more about PaperCon. ##SHARELINKS##

|

|

Tissue360 Forum @ PaperCon 2013 Monday, April 29 - Wednesday, May 1 Atlanta, Ga., USA TAPPI's new Tissue publication, Tissue360o magazine, and TAPPI tissue experts have organized Tissue360 Forum, a comprehensive technical forum covering all aspects of tissuemaking. You will hear about the latest tissue technology, market trends, and pick-up some runnability/operational tips. The program is open to all full PaperCon registrants. Program Overview: Hygenic Products Market Overview Session Chairs: Ken Patrick, Tissue360o Chemistry Solutions for Tissue Making Session Chair: Gary Furman, Nalco Water and Energy Strategies for Tissue Session Chair: Tom Jenn, Kimberly-Clark Premium Tissue Manufacturing Technologies Session Chair: Soren Eriksson, Metso Tissue Controls and Measurement Session Chair: Rene Naranjo, AstenJohnson Yankee Reliability (CEUs provided) Session Chair: Al Coons, Clearwater Paper Converting Efficiencies Session Chair: Kevin Brennan, Ashland Water Technologies See the full Tissue360 Forum program. PaperCon will take place April 27 through May 1, 2013 in Atlanta, Ga., USA. Designed by industry professionals, PaperCon brings together CEOs, mill managers, superintendents, scientsits, process engineers, and suppliers for the largest pulp and paper technical program in the world. No other such event provides such a comprehensive program, networking opportunites, and trade fair among such a distinguished group of industry leaders. Learn more about PaperCon 2013. ##SHARELINKS##

|

The TAPPI Tissue Properties & Manufacturing Course will be held on April 27-28, 2013 in Atlanta, Ga., co-located with PaperCon 2013 and the Tissue Forum. This is a great opportunity to get the most out of your conference experience. This Tissue Properties course is designed for those who desire an introductory-to-intermediate level, comprehensive, and structured course on tissue properties and the effect of manufacturing. The course precedes the Tissue Forum at PaperCon 2013 and is an excellent educational component to these technical sessions. This course will be particularly helpful to non-technical professionals, technical process engineers, operators, suppliers, converters and marketers with 0-5 years of experience in tissue manufacturing. Go to the course website to learn more. ##SHARELINKS##

|

|

PaperCon, April 27 - May 1 in Atlanta,Ga., USA, will include two focused, peer-reviewed sessions within the PIMA Management Program that examine recent developments and usage techniques in Information Technology (IT). Session M6: "Traditional DCS and IT Converge: How to Position Yourself to Take Full Advantage of the Opportunities," chaired by Paul Stecher, SVP and CIO, RockTenn, is geared to DCS control engineers, superintendents, and IT support, and will focus on high speed network and traffic isolation approaches, security considerations, and the latest data integration techniques. Session M8: "Using Industry Proven Software Tools to Drive Mill Efficiencies", chaired by Jim Pigott, MAJIQ, will include three presentations: "Integrating Forecasting to Costing in Dollars and Sense" presented by David Pawelke, MAJIQ; "Thoughts on Paper: Connecting the Supply Chain" presented by Jim Black, OSI Soft; and "Vertically Integrated Real-time Costing for Pulp and Paper Mills," presented by Fredric Karlsson, Enterprise Performance Solutions. Learn more about these sessions and the PIMA Mangement Program at PaperCon. Learn more about PaperCon 2013. ##SHARELINKS##

|

|

Introduction to Nonwovens Tutorial Monday, April 29 3:30 - 5:00pm EST This tutorial will be led by Behnam Pourdehimi, executive director of the Nonwovens Institute at North Carolina State University. As far as business segments that are growing and vibrant, the Nonwovens industry certainly meets those criteria. But Nonwovens means different things to different people. The Nonwovens Institute at North Carolina State University will share an insightful tutorial about the industry, what it includes, which areas are mature, and which are growing. This tutorial is part of the NETInc Innovative Nonwovens Conference, April 29 - May 1, in Atlanta, Ga., USA. This is the only technical conference developed by engineers and technologists to help you understand the innovation behind the science and how it impacts the market. Learn more about NETInc. ##SHARELINKS##

|

|

With more than 80 technical presentations and 50 posters, the 2013 TAPPI International Conference on Nanotechnology for Renewable Materials is packed with the latest applications of renewable nanomaterials. The conference will take place June 24-27, 2013, at the KTH Royal Institute of Technology in Stockholm, Sweden. Register by April 29 for the best rates! This year's conference features keynote presentations that focus on the steps needed to deploy emerging nanotechnologies into the bioeconomy. Hear from these recognized global leaders:

Looking for Additional Nanotechnology Events? Check out the TAPPI Flexible Packabing Symposium: New Technologies, preceding the ICE USA Exposition on April 8 at the Orange County Convention Center in Orlando, Fla. Sessions include Innovations in Nanocomposites, Innovations in Barrier, and Brand Launch, Shelf Appeal, and Authentication. Learn more. ##SHARELINKS##

|

|

The TAPPI International Best Practices on the Corrugator Seminar will be held April 9-11, 2013, in conjunction with SinoCorrugated 2013 in Shanghai, China. The three-day course features an in-depth technical program designed to teach participants about each element in the corrugating process and how to improve box plant operations and box quality. The Best Practices on the Corrugator Seminar is an introductory to intermediate level course that teaches participants how to understand each element in the corrugating process and how to run each component with optimum settings for peak performance to increase productivity, improve quality, and minimize waste. Both old and new equipment will be covered. Participants will also develop an understanding of the critical properties of the raw materials that are vital to guarantee acceptable quality board. Among the key topics to be addressed are: theory of corrugated board production and solutions to common operational problems; distinguishing key features of paperboard/starch adhesive and how to control warp; operating the corrugated production line; controlling and minimizing downtime; maximizing production line efficiency and maintaining quality standards. Find out more about the Corrugator Best Practices Seminar. ##SHARELINKS##

|

|

The NETInc Innovative Nonwovens Conference, April 29 - May 1, 2013, in Atlanta, Ga., USA, is the only technical conference developed by engineers and technologists to help you understand the innovation behind the science and how it impacts the world. Program topics include: Nanotechnology, Binders and Additives, Building Sciences, Health Care and Medical Applications for Nonwovens, Manufacturing Technology, Process Management Technology, and an Intro to Nonwovens Tutorial. With several focused tracks, NETInc offers peer reviewed papers, expert speakers, and exclusive networking opportunities. NETInc participants can also enjoy the full PaperCon program and exhibits, Tissue360 Forum, RPTA P-T Seminar and the OpEx Reliability Workshop with their registration. Learn more about NETInc. ##SHARELINKS##

|

Edited by: A. Mimms, M.J. Kocurek, J.A. Pyatte, and E.E. Wright Liberally illustrated with more than 130 diagrams and photographs, this book includes basic formulas and diagrams to explain the structure of wood, variables affecting the quality and handling of wood chips, pulping chemistry and equipment, the pulping process, and black liquor recovery. It includes a glossary of frequently used terms. Kraft Pulping. View the Table of Contents Preview Sample Pages Product code: 0101R171 Member Price: $58.00 Non-Member Price: $87.00 ##SHARELINKS##

|

|

You still have time to register for TAPPI's Shipping, Receiving and Warehousing Workshop, April 9-10, and be a part of this dedicated group of mills, carriers, warehouses and printers as they gather to discuss and examine positive changes in the industry and innovative ways to reduce roll damage. David Schirmer, Vice President and General Manager of Hearst Enterprises will Keynote. Schirmer is responsible for paper procurement for divisions of Hearst Corp. including Hearst Magazines and Hearst Newspapers and is one of principles of Newsprint Purchasing LLC. ##SHARELINKS##

|

|

Join leading experts in the field of flexible packaging and new technology developments as they share their insights on the emerging areas of nanotechnology within packaging, April 8, at the TAPPI PLACE Flexible Packaging Symposium: New Technologies, an ICE USA pre-conference seminar at the Orange County Convention Center in Orlando, Fla., USA. This three-session event is a first-ever collaboration between two of TAPPI's premier technical divisions - PLACE (Poloymers, Laminations, Coatings and Extrusions) and the Nanotechnology Division. Sessions include Innovations in Nanocomposites, Innovations in Barrier, and Brand Launch, Shelf Appeal, and Authentication. Featuring presenters from Verso Paper, Enercon Industries, Cloeren, NOVA Chemicals, IMERYS, and more! View the preliminary program. Learn more and register. ##SHARELINKS##

|

|

Strengthen your understanding of the corrugating process, and linerboard and medium performance properties and manufacture with TAPPI's Linerboard Medium & Corrugated Box Manufacture Course, April 15-16, at the Holiday Inn in Neenah, Wis., USA. With an emphasis on helping attendees improve corrugating box performance and runnability, this popular introductory to intermediate level course is ideal for process engineers and operators in linerboard and medium manufacturing facilities and corrugating and converting plants. Instructors Michael J. Kocurek, Professor Emeritus, of Paper Science & Engineering at North Carolina State University, and Jon Porter, Senior Trainer / Process Specialist for Fosber America will address:

Register by March 15 to take advantage of the Early Bird registration discount. Join TAPPI or renew your membership for the best rates! ##SHARELINKS##

|

|

Guidelines for the Safe Operation of Steam Heated Paper Machine Dryers Guidelines for the Safe Operation of Steam Heated Paper Machine Dryers. ##SHARELINKS##

|

|

PaperCon Session: Insights into Effective Labor/Management Relationships Panelists: ##SHARELINKS##

|

|

The Introduction to Traditional and Emerging Printing Technology Course will be co-located at the 2013 PaperCon Conference, April 27-29, 2013, in Atlanta, Ga., USA. This is an introductory course on printing methods and applications, designed for those who need to understand print quality, attend print trials, trouble shoot print problems or are generally new to printing operations. It will be taught by printing experts from TAPPI's Coating and Graphic Arts Division and is an excellent complement to the Coating Program at PaperCon. As an added bonus, the course will include a tour of Hewlett-Packard's new state-of-the art facility where production laser and inkjet presses will be demonstrated. Course attendees may also join the Coating and Graphic Arts Opening Session where printing visionary Frank Romano is giving the keynote address. Learn more and register online. ##SHARELINKS##

|

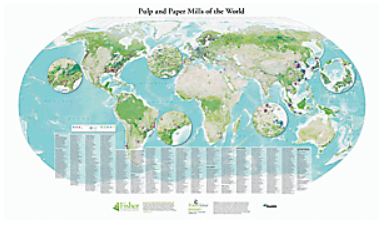

One of TAPPI's most exciting new products is the wall-sized, laminated 2013 Pulp & Paper "Mills of the World" Map. A winning combination of high quality print and paper stock along with brilliant colors makes this the perfect map to frame and hang in your office. The "Mills of the World" map features include:

Each map will be shipped in a protective tube, ready for display. ##SHARELINKS##

|

Are you ready to go further, faster in your safety career? The Certified Occupational Safety Specialist (COSS) class can take you there. The COSS Class is Unique Not only will you learn how to read and understand the OSHA 1910 and 1926 CFRs and help your company avoid OSHA citations that cost millions of dollars, but more importantly, by learning how to work safely on a job site, you can teach your company how to lower fatalities and near misses. Almost 47% of COSS graduates responding to our survey indicate that, since taking COSS, their company's injury rate and/or OSHA recordables have decreased by as much as 25% and others attest to as much as a 100% decrease! Request a Course Outline & Syllabus for more information. The class also addresses the psychology of safety, the true cost of an accident, hazard recognition, how to start up a health and safety program, behavior based safety, system safety, and much more! What Will You Receive? Upon successfully completing the class, you will obtain your national Certified Occupational Safety Specialist (COSS) designation, your OSHA 10-hr. card of completion in construction, and your OSHA 10-hr. card of completion in general industry. National Program Recognitions COSS is currently one of only 37 programs in the world recongnized and accredited by the American Petroleum Institute (API). In addition, the certifying body for construction education for colleges, universties and technical/trade schools, American Council for Construction Education (ACCE), has also recongnized our program. COSS is the only non-degree program to receive this national endorsement. Lastly, COSS has been established as a mandatory course for students in the Construction Management Program at Louisiana State University. Program Content The program consists of 40 hr. of hands on, face-to-face learning, which is delivered by an Authorized OSHA outreach trainer in both construction and general industry. Case studies and workshops are used extensively to bring learning objectives into focus. Guest speaker from areas such as OSHA and other governmental agencies are used to enhance the learning experience. Student presentations, daily quizzes, practical reviews, and a comprehensive final exam will allow you to demonstrate your competency. Prerequisites The only prerequisite for the COSS class is you must have a high school diploma or equivalent. In each class, we tend to have a mix of non-experienced, first time safety persons, as well as safety professionals who have been in the safety field for 20+ years. But, we have learned that regardless of the numbers of years of experience you have in safety, everyone leaves the COSS class with a wealth of knowledge! Visit the COSS website for FAQs, testimonials and a list of clients that have taken COSS. Register now. If you would like more information on the COSS program, contact Beth Gordon at 877-610-2677 ##SHARELINKS##

|