| Archive | Advertise | tappi.org | January 2024 |

![]() Print this article | Send to Colleague

Print this article | Send to Colleague

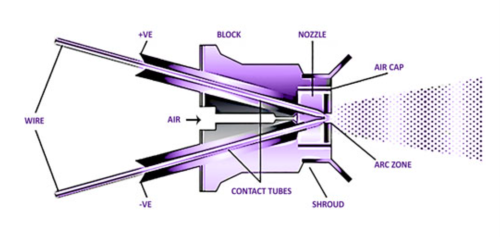

Thermal spray coatings are now common on cast and steel yankee dryers. Of the yankee dryers with thermal spray coatings (TSC), approximately 90% are expected to be electric arc spray (EAS) applications. The EAS process uses cored wires that are formed by wrapping a metal sheath around powdered metals. Cored wires were developed in the US in 1954 and have been utilized for yankee dryer surface coatings since 1995. This Technical Information Paper (TIP) will only discuss cored wire thermal spray coating of yankee dryers.

Key points include an overview of the EAS process including key variables, project safety, quality control and long-term maintenance.

Date of Publication: January 31, 2024

Purchasing Link: https://imisrise.tappi.org/TAPPI/Products/01/0108042509.aspx

Working Group Members:

Clive Butler – Chair, A.Celli

Adam Offerdahl, Toscotec North America

Bernard Hoeger, GrandBay, Trinidad Tissues Ltd

Buddy Lovick, GAPAC

Don Adams, Procter & Gamble

Jerry Jessick, Fusion Integrated Solutions

Jeffery Peters, BTG

Neli Jeske, GAPAC

Simone Pieruccini, Toscotec Italy

Ted Johnson, Triosim

Tommy Kallerdahl, Valmet

If you would like to share your experience with Standards, TIPs or ISO TC 6, please write to standards@tappi.org and the TAPPI Standards team will be happy to interview you.

TAPPI Standards guidelines require that all TAPPI members receive notification of any proposed new Standard or TIPs. This message is being sent to you because you are a TAPPI member; have purchased TIPs or Standards products from TAPPI; or because you have previously expressed interest in this topic.

TAPPI is the leading technical association for the worldwide pulp, paper and converting industry.

15 Technology Parkway South | Norcross, GA 30092 | www.tappi.org

1-800-332-8686 (US) | 1-800-446-9431 (Canada) | +1-770-446-1400 (Worldwide)