This TIP provides a review of the theory of thermocompressor operation as well as some practical guidelines and common mistakes on typical applications.This TIP provides a review of the theory of thermocompressor operation as well as some practical guidelines and common mistakes on typical applications.

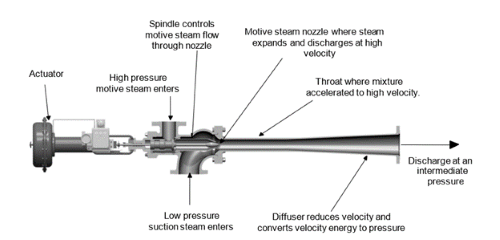

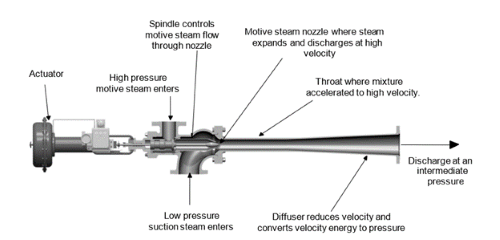

Thermocompressors are widely used in paper machine steam and condensate systems. A thermocompressor is a jet ejector that uses high-pressure motive steam to recompress lower pressure steam. Typical applications include re- circulating blowthrough steam in a group of dryers or a Yankee cylinder, or boosting low-pressure steam for use in a system requiring higher operating pressures.

Please note that it is essential to establish proper design conditions, since thermocompressors are custom built for each application. An incorrectly designed unit can be unstable, uncontrollable, and waste significant amounts of steam.

The intention of this TIP is not to provide an engineering guideline for detailed design of thermocompressors or thermocompressor systems – this is a task that should be reserved for companies or individuals with specialized tools and expertise in these applications – but rather to provide an overview of thermocompressor application and operation.

Date of Publication: September 29, 2023

Purchasing Link: https://imisrise.tappi.org/TAPPI/Products/01/0108040466.aspx

Working Group Members:

Mike Soucy – Chair, Kadant Johnson Systems

Dick Reese, Dick Reese and Associates

Christian Coffman, Fulton Systems

Pekka Kormano, International Paper

Zeke Eskender, International Paper

Alan Ives, Kadant Johnson LLC

Mark Rivard, Valmet Ltd

Alain Genereux, WestRock

Thank you to the Working Group Chair and Working Group Members for your contribution to this important industry resource!