| Archive | Subscribe | Printer-Friendly Version | Advertise | tappi.org | TAPPI Press Catalog | July 2023 |

TAPPI Standards and TIPs News!

Join a Working Group Today

Don't miss the chance to vote on Standard reviews.

Click here to join any Standard-Specific Interest Group (SSIG)

|

New or Revised Standards, TIPs, and Useful Methods

Check here the list of TAPPI Technical Information Papers (TIPs) recently published:

We extend our special appreciation to the following volunteers who served as Working Group Chairs in the recently published reviews of TAPPI TIPs:

Special note: Documents appearing in the TAPPI online version of the Standards and TIPs are updated once a month (usually around the 30th). So it is possible that there is a delay between the publication announcement and the posting online. If you are a subscriber to the online access to Standards and TIPs and you are in a hurry for new documents that have not yet been posted, you can send a request for TIPs to tip@tappi.org or for Standards to standards@tappi.org. STAR of the Month

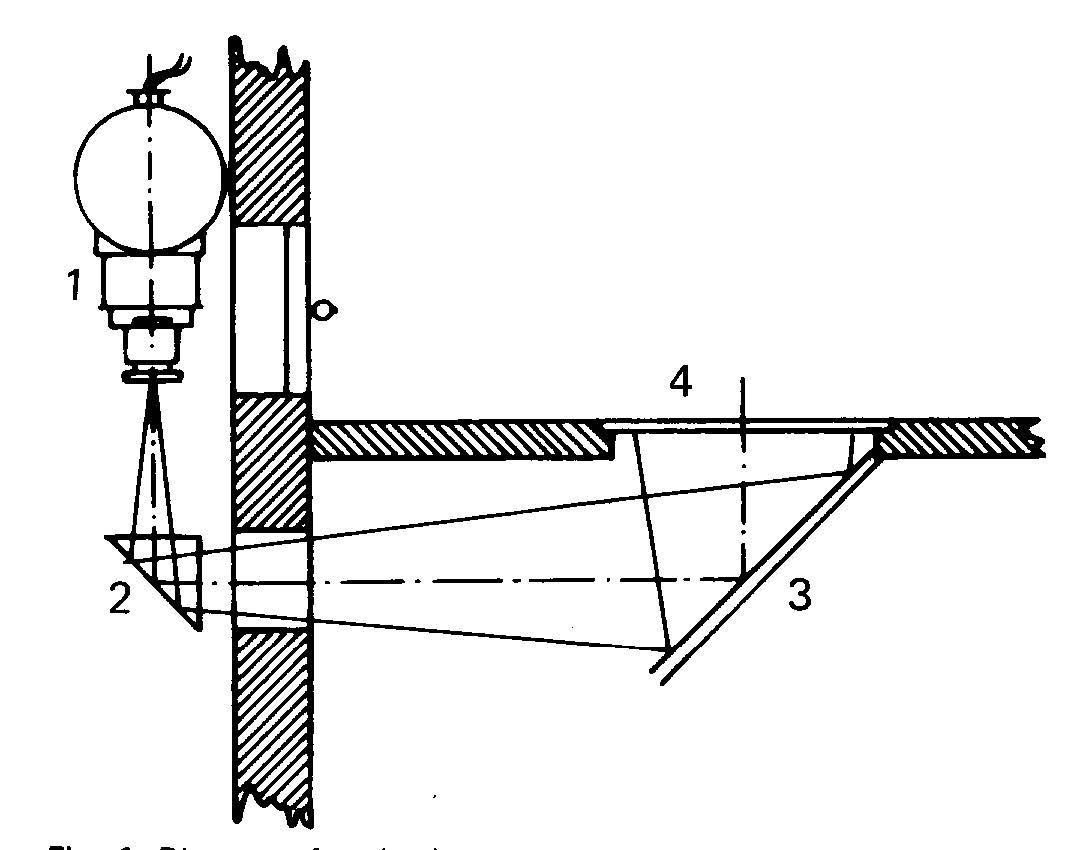

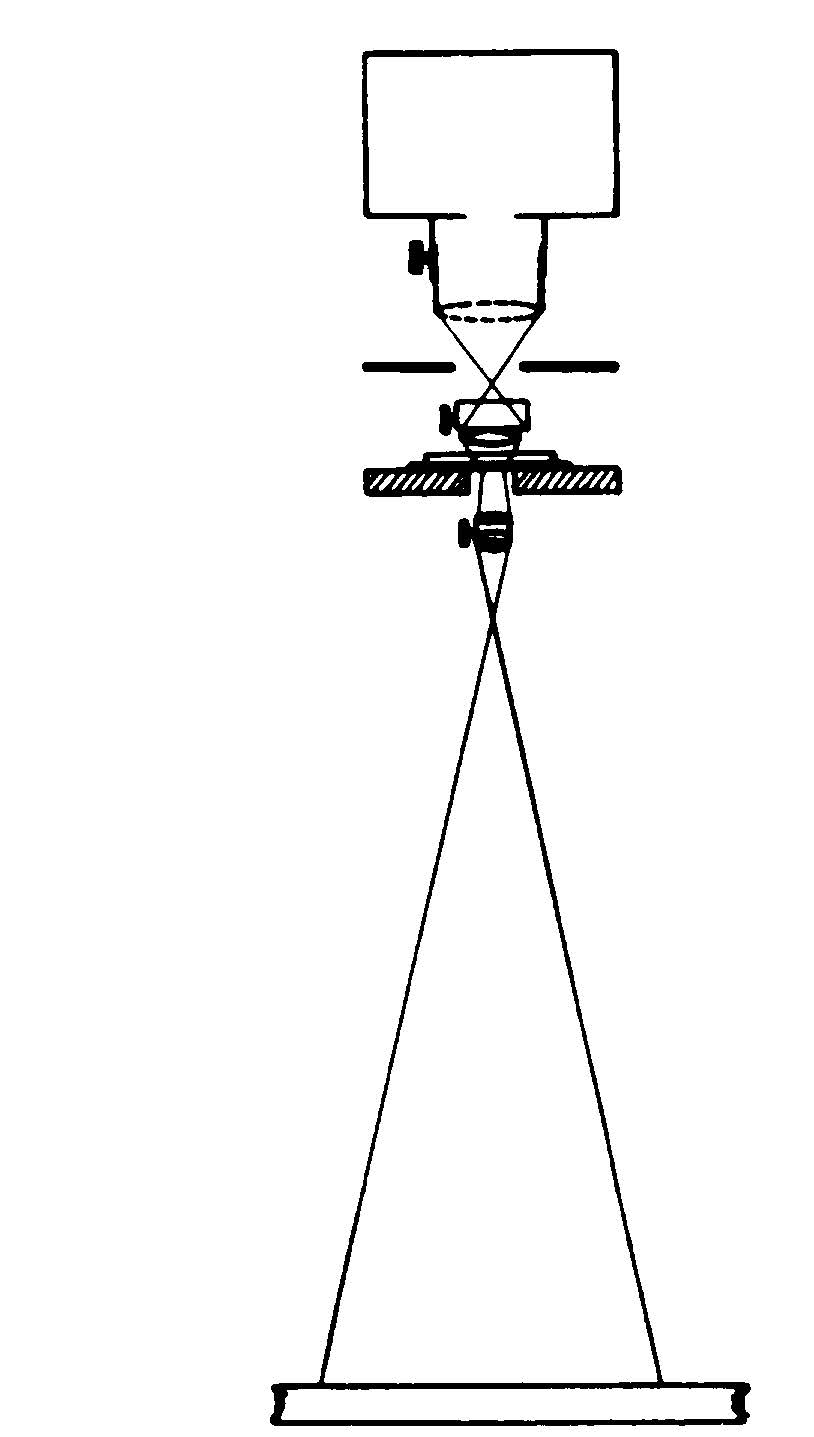

TAPPI/Standards T 232 cm-23: Fiber Length of Pulp by Projection Scope: 1.1 This is a projection method (1) by which the weighted average fiber length of a pulp may be measured relatively quickly and easily.

Do you have an idea for a NEW TAPPI Standard or Technical Information Paper? We want to hear about it! Please fill out and submit the New Idea Submission form. TAPPI Standards in Ballot

TAPPI TIPs under review

Listed below are TAPPI TIPs that were recently submitted to the Working Group for review. The date when the Work Item was opened is shown for each TIP, as well as the Subject Category under which the TIP is assigned and the Working Group Chair's (WGC) name. The target completion date for the review of each TIP is one year after the opening of the Work Item. 0106 – Coating Pigments 0304 – Process Control & Quality Assurance 0305 – Production 0404 – Water Removal 0416 – Steam & Power/Energy Management If you would like to participate in the Working Group to review any of these TIPs, please write to tip@tappi.org. Proposed New TIPs

The scope of the proposal for a new Technical Information Paper is shown below, as well as the assigned Subject Category, the date when the Work Item was opened, the title of the new proposal and the name of the Working Group Chair (WGC). 0420 – Maintenance and Mechanical Engineering 0425 – Yankee Dryer 0425 – Yankee Dryer 0425 – Yankee Dryer 1101 – Process Control If you would like to join the Working Group or review the final draft for this new proposal, please write to tip@tappi.org Members for Working Groups of TIPs Needed

Volunteers for the following working groups of Technical Information Papers (TIPs) are needed. All Working Groups of TIPs require a minimum of 3 TAPPI members from 3 different companies in order to review a TIP. The following TIPs do not have an assigned Working Group Chair and Working Group Members to initiate the review. Working Group Chairs Needed:

Working Group Members Needed:

If you would like to join a Working Group of a TIP, please write to tip@tappi.org for more information. General Announcements

Stay Sharp with TAPPI Training, eLearning and Webinars: Use your TAPPI Member benefits to catch-up on your professional development requirements, stay ahead of the competition, learn something new or just amaze your co-workers with some new-found knowledge. Whether you've got personal goals in mind, are focused on career development, or leading your team through continuous improvement, TAPPI has you covered with TAPPI Academy. Your membership investment gives you access and discounts to:

TAPPISAFE Not a TAPPI Member? Got Questions? Pass along the good news with our Refer a Friend Program. Did You Know

... that to participate in the balloting process for TAPPI Standards you must sign up for the Standard-Specific Interest Groups (SSIGs)? Drafts are available for anyone... that to participate in the balloting process for TAPPI Standards you must sign up for the Standard-Specific Interest Groups (SSIGs)? Drafts are available for anyone to review, but to vote and comment you must be a member of the SSIG. Each Standard has its own SSIG – so you have to sign up for each Standard that you have an interest in. Links to all of the SSIGs (by subject category) can be found on the Subject Category for Standards web page. Visit tappi.org/JoinStandards to join now. Acronyms You May Need to Know

TIP = Technical Information Paper Q&SMC = Quality and Standards Management Committee SSIG = Standard-Specific Interest Group SARG = Standards Advisory Review Group WI = Work Item WG = Working Group WGC = Working Group Chair om = Official Method pm = Provisional Method sp = Standard Practice cm = Classical Method ss = Standard Specification sg = Standard Guideline gl = Standard Glossary wd = Withdrawn Standard UM = Useful Method Searching and Ordering TAPPI Standards, TIPs, and Useful Methods

Details on how to search and order TAPPI Standards, TIPs, and Useful Methods can be found on the TAPPI website’s Search and Order page. All individual TIPs or Standards are available for electronic or paper delivery. For electronic delivery, the documents are e-mailed in PDF format. Hard copy documents can be mailed or faxed, but shipping and handling costs will apply. For Individual TIPs, order Item Number: 0108____ (Insert TIP number) For Individual Standards, order Item Number: 0104T____ (Insert Standard number) For individual Useful Methods, order item number: 0104UM_____ (Insert UM number) List price: $49; TAPPI member price: $32. There are no shipping or handling charges for electronic documents. The TAPPI CD of Standards, TIPs, and UMs has been discontinued for 2021. An Individual or Company License for access to the continually updated collection of Standards, TIPs, and UMs via the web is the best way to always have a current set of documents accessible. A print-on-demand version of either the Standards, TIPs, or UMs, current and updated as of the date printed, is also available. For information and quotes on company licenses, contact TAPPI Press (press@tappi.org) or +1-770-209-7277. For regular orders (including individual online licenses), contact Member Connection at 1-800-332-8686 (US), 1-800-446-9431 (Canada), or +1-770-446-1400 (international), or order on line at www.tappi.org. ---------------------------------------------------------------------------------------------------------------- Search and Order Individual Access or Company license Join a SSIG Develop a TIP Standards Guidelines TIPs Guidelines |

TAPPI Standards guidelines require that all TAPPI members receive notification of any proposed new Standards or TIPs. This message is being sent to you because of your affiliation with TAPPI; have purchased TIPs or Standards products from TAPPI; or because you have previously expressed interest in this topic.

TAPPI is the leading technical association for the worldwide pulp, paper and converting industry.

15 Technology Parkway South | Suite 115 | Peachtree Corners, GA 30092 | www.tappi.org

1-800-332-8686 (US) | 1-800-446-9431 (Canada) | +1-770-446-1400 (Worldwide)

TAPPI Privacy Policy