| Archive | Subscribe | Printer-Friendly Version | Advertise | tappi.org | TAPPI Press Catalog | November 2024 |

|

New or Revised Standards, TIPs, and Useful Methods

T 1014 om-24 Moisture sensitivity of fiber glass mats (Revision) Special thanks to the SSIG members below for being the Working Group Chairs in the recently published reviews of TAPPI Standards: Brian Traynor - WGC for T 1014 The TAPPI Standards Department would also like to express its gratitude to all volunteers who participated in the review of those Standards as SSIG members. Eleven TAPPI Standards approved as American National Standards The following TAPPI Standards have been approved as American National Standards by the ANSI Board of Standards Review: New American National Standards: Approved reaffirmation of current American National Standards: Notices of the approvals of the TAPPI Standards as American National Standards were placed in the November 8th, 2024, and November 15th, 2024 editions of ANSI Standards Action. Check here the list of TAPPI Technical Information Papers (TIPs) recently published: TIP 0416-20 Recovery boiler sootblowers: practical guidelines (Revised) We extend our special appreciation to the following volunteers who served as Working Group Chairs in the recently published reviews of TAPPI TIPs: Danny Tandra - WGC for TIP 0416-20 Special note: Documents appearing in the TAPPI online version of the Standards and TIPs are updated once a month (usually around the 30th). So it is possible that there is a delay between the publication announcement and the posting online. If you are a subscriber to the online access to Standards and TIPs and you are in a hurry for new documents that have not yet been posted, you can send a request for TIPs to tip@tappi.org or for Standards to standards@tappi.org. STAR of the Month

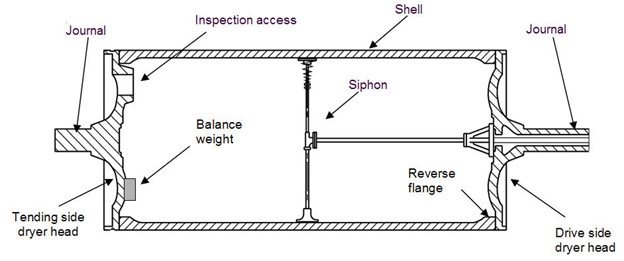

This TIP intends to provide guidelines that may be used to increase the maximum allowable working pressure of American Society of Mechanical Engineers (ASME) certified cast iron paper machine dryers. This process, in which no physical change is made to the dryers, is defined as an “alteration” by the National Board Inspection Code. Machine capacity may be increased by increasing dryer steam pressure. This benefit may be accompanied by an increase in machine speed.

Date of Publication: October 31, 2024 Purchasing Link: http://imisrise.tappi.org/TAPPI/Products/01/0108042014.aspx Working Group Members: Margaret Gorog – Chair, Houghton Cascade Holdings LLC If you would like to share your experience with Standards, TIPs or ISO TC 6, please write to standards@tappi.org and the TAPPI Standards team will be happy to interview you. TAPPI Standards in Ballot

Listed below are TAPPI Standards that have recently gone out for ballot to the corresponding Standard-Specific Interest Group (SSIG). The date in parentheses is the closing date for voting. T 480 om-20 Specular gloss of paper and paperboard at 75 degrees (December 12, 2024) The TAPPI Standards regulations require public review of standards that are up for ballot. Send a message to standards@tappi.org if you want to request a copy of the draft in ballot. If you would like to participate in the SSIGs that review and vote on the Standards, please contact TAPPI Standards Department at standards@tappi.org. TAPPI TIPs under review

Listed below are TAPPI TIPs that were recently submitted to the Working Group for review. The date when the Work Item was opened is shown for each TIP, as well as the Subject Category under which the TIP is assigned and the Working Group Chair's (WGC) name. The target completion date for the review of each TIP is one year after the opening of the Work Item. 0402 - Corrosion & Materials Engineering If you would like to participate in the Working Group to review any of these TIPs, please write to tip@tappi.org. SSIG Members Needed

The Standard-Specific Interest Groups (SSIGs) for the following Standards are in need of additional members. These groups may or may not have ballots currently open. T 266 om-24 Determination of sodium, calcium, copper, iron and manganese in pulp and paper by atomic absorption spectroscopy Participating in a SSIG is free and open to anyone interested. Join now! If no progress is made on balancing these SSIGs, then the respective methods may be considered for withdrawal at the next Q&SMC meeting. If you have an interest in becoming a member of either of these SSIGs please contact standards@tappi.org Members for Working Groups of TIPs Needed

Volunteers for the following working groups of Technical Information Papers (TIPs) are needed. All Working Groups of TIPs require a minimum of 3 TAPPI members from 3 different companies in order to review a TIP. The following TIPs do not have an assigned Working Group Chair (WGC) or working group members to complete the review: Working Group Chairs Needed: TIP 0404-20 Physical characterization of press fabrics: basis weight, air permeability, and pressure uniformity Working Group Members Needed: TIP 0402-13 Guidelines for specification and inspection of electric resistance welded (ERW) and seamless boiler tube for critical and non-critical service If you would like to join a Working Group of a TIP, please write to tip@tappi.org for more information. Members for Working Groups of Useful Methods Needed

Volunteers for the following working groups of Useful Methods (UMs) are needed. All Working Groups of UMs require a minimum of 3 TAPPI members from 3 different companies in order to review a UM. The following UMs do not have an assigned Working Group Chair (WGC) to initiate the review: UM 3 Determination of useful fiber in bagasse Working Group Members Needed: Standards Coming Up For Review

The system for review and development of TAPPI Standards requires an announcement of review dates so that any interested TAPPI parties may access the drafts, submit comments, and/or join the Standard-Specific Interest Group (SSIG) to cast an official vote. Listed below are the Standards that will be up for review in 2025. The date indicated is the target date on which the draft will be distributed to the Standard-Specific Interest Group (SSIG) for that particular Standard. T 1215 sp-21 The determination of instrumental color differences (May 17, 2025) Any interested individuals who wish to be part of the voting for any Standard should send a message to standards@tappi.org and request voting membership on the corresponding SSIG, prior to the target ballot date, if possible. Anyone who joins the SSIG before the target balloting date will receive a notice of the ballot. U.S. TAG to ISO TC 6

Next TC 6 Meeting(s) – Need to pre-register to attend. If you are a member of any working group (WG), please think about attending at least one of these meetings, or if you can’t please inform HOD of any important issues you may have. If you would like to attend the next plenary meetings virtually, please reach out to isotc6@tappi.org. TC 6 (Paper, board and pulps) TC 6/SC 2 (Test methods and quality specifications for paper and board) ISO TC6 has new leadership: David Loebker of Procter & Gamble is now serving as Chair, with Nicholas Riggs of Industrial Physics as Vice-Chair. Additionally, Scott A. Graham from L&W Products has joined ISO TC6. If you would like to know more or join the U.S. TAG to ISO TC 6, please write to isotc6@tappi.org. General Announcements

Getting started is easy. Do you have just a general idea for a Standard, or are you farther along and have a substantial draft? If you just have a general idea for a Standard or TIP, complete the New Idea Submission form. TAPPI will review your idea and identify an appropriate committee or group to work on your suggestion. If you are further along, send an initial draft to standards@tappi.org. From there, the TAPPI Standards Manager will guide you through the appropriate process to finalize and approve the new document. Withdrawal of TAPPI T 575 om-13 The Official Method T 575 om-13 Roughness of paper and paperboard, stylus (Emveco-type) method has been withdrawn due to a lack of timely completion of the review and the stylus referenced in the Standard is no longer manufactured. Withdrawn Standards are available free for TAPPI members and for a $10 charge to nonmembers. To initiate a Work Item to revise and reinstate a withdrawn Standard, contact standards@tappi.org. Did You Know

... that to participate in the balloting process for TAPPI Standards you must sign up for the Standard-Specific Interest Groups (SSIGs)? Drafts are available for anyone to review, but to vote you must be a member of the SSIG. Each Standard has its own SSIG – so you have to sign up for each Standard that you have an interest in. Links to all of the SSIGs (by subject category) can be found on the SSIG Join Page. When you click on a Subject Category, it will display links to related SSIGs. Acronyms You May Need to Know

For details on these commonly used acronyms in the development of TAPPI Standards and TIPs, please see the Standards Guidelines and the TIP Guidelines, or send your questions to standards@tappi.org.

Searching and Ordering TAPPI Standards, TIPs, and Useful Methods

Details on how to search and order TAPPI Standards, TIPs, and Useful Methods can be found on the TAPPI website’s Search and Order page. All individual TIPs or Standards are available for electronic or paper delivery. For electronic delivery, the documents are e-mailed in PDF format. Hard copy documents can be mailed or faxed, but shipping and handling costs will apply. For Individual TIPs, order Item Number: 0108____ (Insert TIP number) For Individual Standards, order Item Number: 0104T____ (Insert Standard number) For individual Useful Methods, order item number: 0104UM_____ (Insert UM number) List price: $53; TAPPI member price: $35. There are no shipping or handling charges for electronic documents. The TAPPI CD of Standards, TIPs, and UMs has been discontinued since 2021. An Individual or Company License for access to the continually updated collection of Standards, TIPs, and UMs via the web is the best way to always have a current set of documents accessible. A print-on-demand version of either the Standards, TIPs, or UMs, current and updated as of the date printed, is also available. For information and quotes on company licenses, contact TAPPI Press (press@tappi.org) or +1-770-209-7277. For regular orders (including individual online licenses), contact Member Connection at 1-800-332-8686 (US), 1-800-446-9431 (Canada), or +1-770-446-1400 (international), or order online at www.tappi.org. Individual Access or Company license Join a SSIG Develop a TIP TIPs Guidelines |

TAPPI Standards guidelines require that all TAPPI members receive notification of any proposed new Standards or TIPs. This message is being sent to you because of your affiliation with TAPPI; have purchased TIPs or Standards products from TAPPI; or because you have previously expressed interest in this topic.

TAPPI is the leading technical association for the worldwide pulp, paper and converting industry.

15 Technology Parkway South | Suite 115 | Peachtree Corners, GA 30092 | www.tappi.org

1-800-332-8686 (US) | 1-800-446-9431 (Canada) | +1-770-446-1400 (Worldwide)

TAPPI Privacy Policy