| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | September 2017 |

Are You Overlooking Converting?

Bruce Janda, Innovaspec The North American tissue business has become one of the most dynamic sectors in the paper industry. No one could have imagined 20 years ago that the number of tissue producing companies would be growing markedly today, instead of shrinking due to expected consolidation. The number of tissue operating companies has increased by 39 percent in the last 10 years. The next two years will see the addition of more than 455,000 tpy of tissue capacity. We appear to be in the middle of an explosion of new tissue capacity additions as we continue to hear frequent announcements about new machines. This will require tissue makers to improve our game to remain relevant. One thing does appear to have stayed the same: the reduced attention our industry tends to give to converting versus new tissue machines and their technology. The big equipment makes for better conversation and bragging rights from the engineering department to Wall Street, but the fact remains that tissue products are built in converting, where the most value is added. If you ask any customer who buys tissue for the distribution channels—from retail to hotels, restaurants, and factories—they mostly care about your converting equipment. They want to know what pack sizes, sheet counts, packaging options, embossing, printing, and palletizing options they can get. It is not easy to engage them in much conversation about the tissue machine equipment and process details except for how soft it makes the tissue.

The cost of a tissue machine causes us to pay strict attention to its quality, runnability and productivity measures. Converting often gets less attention but it has a larger role to play. Tissue converting efficiency rates remain very low (40-70 percent) compared to tissue machines. This is attributed to poor operations practices, extensive setup times, maintenance issues and equipment failures. Low tissue converting efficiency is a large bottleneck and represents a large potential improvement area for overall tissue manufacturing results.

However, the quality and variability of base sheet properties also have a large effect on converting product quality, runnability and productivity that is less well understood and measured. The tissue base sheet jumbo rolls coming into converting have variable and nonuniform properties that are rarely measured but can have a large effect on converting productivity. Matching tissue making and converting operations for best collaborative quality and productivity is the key to successful tissue manufacturing. This is one of the greatest opportunities for the North American tissue industry.

Scientists Frederic Parent, Javad Saberian, and Nina Geng at FPInnovations, a Canadian not-for-profit center for forest sector research and innovation, have embarked on a program to measure tissue base sheet defects and variability to correlate with converting productivity. Typical tissue base sheet variations they cite include:

Tissue base sheet defects they consider include:

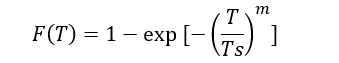

FPInnovations has developed an offline scanner to quantify and characterize base sheets CD variability. CD tension profiles can be linked directly to converting observations. Strength uniformity is another key variable and a tighter of higher uniformity of strength properties results in fewer breaks in converting. FPInnovations has also developed a uniformity factor "m" from the Weibull distribution of measured base sheet uniformity to describe the level of uniformity to compare to converting results. The factor "m" is determined from the equation shown below. The higher the m value, the better the tissue base sheet uniformity, which results in improved converting efficiency.

Initial results from the FPInnovations work look promising toward correlating converting efficiency to the m factor or base sheet uniformity. More work is required to better define the link between base sheet uniformity and converting efficiency but this is a good step forward.

Tissue making technology continues to evolve. TAD and other structured processes for base sheets will soon account for 40 percent of the tons produced in North America. This is another area where converting needs more attention. The strength and stretch relationships in structured tissue are dramatically different from conventional tissue. The softer and bulkier base sheets make for higher value products but require much more skill and understanding to maintain acceptable converting plant results.

The converting process and equipment required to successfully convert structured tissue base sheets requires adjustments and or updates to be successful. Converting process equipment has been changing to meet these challenges. Understanding these requirements is key to selecting equipment and converting process adjustments to result in good converting efficiency and product quality.

Improve Converting Skills With Targeted Course

Get answers to all your converting questions at TAPPI’s Tissue 202 Roll Converting Operations course in Green Bay, WI September 19-21. This course includes a distinguished panel of converting process and equipment experts from six different companies who will cover the entire roll forming process. The course covers the need to adjust to structured tissue base sheets with lab time spent on pilot converting equipment comparing operations settings for conventional tissue versus TAD.

The course will cover the base sheet and how its properties affect converting, including common sources of defects and causes on the tissue machine. Discussion will include converting safety and dust collection, as well as embossing and its effect on product properties and runnability. The course also covers log building and sawing operations, chemical selection for adhesive, and other converting applications in converting. Line integration, quality measurement and packaging are new additions to the curriculum this year. Key learning outcomes are:

Keep your tissue manufacturing moving forward with improved converting skills. Engage the panel of experts to boost your knowledge. Tissue converting success requires more than just making little rolls out of big ones.

|