| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | December 2017 |

Lucart Boosts Production Performance with a New Tissue Rewinder

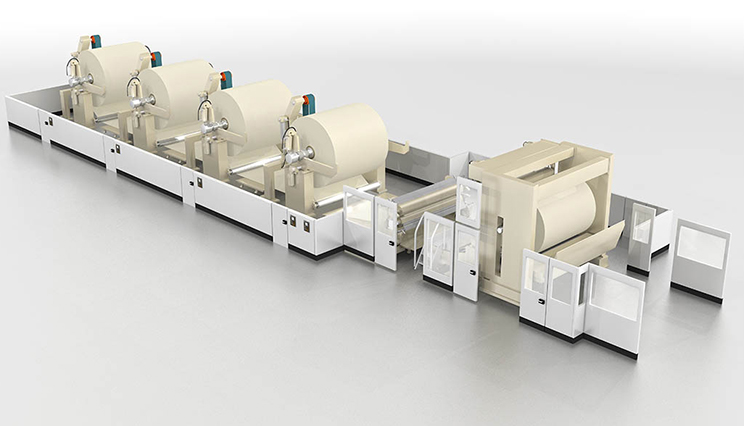

Lucart has recently started up a new tissue rewinder TT WIND-P at its facility in Laval sur Vologne, France. It was supplied supplied by the Italian machinery producer Toscotec.

The tissue rewinder model TT WIND-P features two unwind stands and handles parent rolls of 2,900 mm width and 2,600 mm diameter at the maximum speed of 1,400 m/min. Toscotec’s machinery is equipped with a slitting unit of 150 mm width, automatic control of all unwinding and rewinding operations and sectional drive system.

This turnkey project includes Toscotec’s proprietary automation and control system. This recently developed system is integrated into Toscotec’s rewinder technology and guarantees a significant increase in efficiency and productivity. Supervision during erection, commissioning and start-up was performed by Toscotec’s Service division YES – Your Expert Service.

The new state-of-the-art rewinder serves the PM 9 tissue machine and represents another important collaboration between Lucart and Toscotec after the rebuilding of PM 10 in late 2016.

Lucart’s president Alessandro Pasquini declared: "Toscotec has been working with us since 2008. They have grown to become a strong partner for Lucart and we are now cooperating on a number of interesting projects. This new rewinder at Laval sur Vologne mill has been performing well and meets our expectations."

Lucart’s history goes back to the 1930s when the Pasquini family decided to set up a papermaking factory in Villa Basilica (Lucca). Today, the group’s total production capacity is over 300,000 tons/year with 10 paper machines and 58 converting lines.

Toscotec is a turnkey project supplier to the global paper industry. Since 1948, Toscotec has offered complete production lines, plant retrofits, turnkey projects and individual machineries. The group serves all the leading paper producers with customized solutions, relying on the experience gained in over 60 years of activity.

For more info: www.toscotec.com

|