| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | May 2018 |

Voith’s ProTect™ Unit Provides Press Fabric Measurements

Voith recently introduced a product that greatly improves personnel safety when measuring performance of press felts. Historically, a GP employee or a PM press felt representative would take a hand-held scanning device and while the paper machine was running walk across the width of the paper machine taking press felt measurements. This was deemed an unsafe practice within GP and industry. Essentially, no one is allowed inside the operating window of a running paper machine.

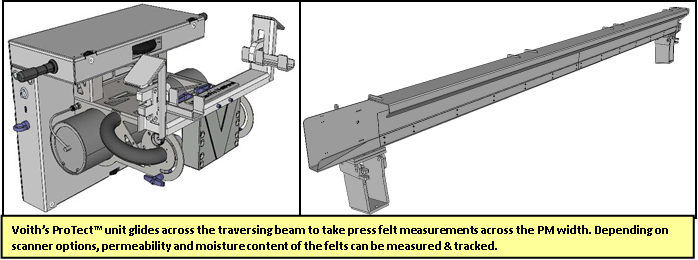

What Voith developed is a carrier system called ProTect™ that essentially takes their handheld scanning device (or that of other suppliers) and provides a safe way to carry out this important task. Voith engineered a fixed traverse beam that mounts across the paper machine and adds self-propelled equipment that holds the scanner to take press felt measurements safely. The scanner itself is purchased separately. While not in use, the portable hardware is typically removed and placed on a charging station. What Voith developed is a carrier system called ProTect™ that essentially takes their handheld scanning device (or that of other suppliers) and provides a safe way to carry out this important task. Voith engineered a fixed traverse beam that mounts across the paper machine and adds self-propelled equipment that holds the scanner to take press felt measurements safely. The scanner itself is purchased separately. While not in use, the portable hardware is typically removed and placed on a charging station. These fixed beams are made of stainless steel and have an insertion area outside the operating area of the PM. Further, separate beams can be purchased to provide access to additional felt locations on a paper machine or to other paper machines. This allows one portable ProTect unit to service several positions within a paper machine or multiple paper machines.

Of equal interest is what can a scanner offers besides press felt wear? Depending on its configuration, these instruments can measure permeability and moisture content of the felts.

Permeability: Permeability is measured by the resistance to a high-pressure water stream. By measuring the water permeability of the felts, clogging and wear are easily discovered and the potential to optimize the pressing with regards to paper quality and dewatering is made possible. The instrument also measures felt length as well as giving measurement positions in relation to the machine width. The instrument can be used to optimize the conditioning system as well as for quick troubleshooting. Regular measurements with these instruments can lead to optimized use of cleaning chemicals, increased felt life, efficient dewatering, high and uniform product quality, and reduced machine downtime.

Moisture measurements: These are completed using a microwave signal. Regular measurements with these instruments are the key to optimal dewatering in the press section and lead to fewer problems with machine disturbances and downtime – which in turn means big cost savings. By measuring the felt’s water content, before and after the press, dewatering can be easily optimized. Effective dewatering in the press section can reduce energy consumption in the drying section and increase production considerably; a 1 percent increase of dry content in the press section gives a 4 percent reduction in energy use in the dryer section. To optimize dewatering, action should be taken in the press section to avoid additional energy costs in the dryer section – something that quickly pays for itself. Typical range is 0-3,000 gH2O/m² for moisture content and 50-3000 mL/min for permeability. To learn more on this innovation, contact Wyatt Boyett, Voith’s business manager for this product: Wyatt.Boyett@voith.com, www.voith.com.

|