| Archive/Subscribe | TAPPI.org | Advertise | TAPPI Press Catalog | May 2020 |

Fabio Perini and MTC Offer Prompt Delivery for Converting and Packaging Machines and Lines

The fear generated by the coronavirus and the closures in several countries to fight the pandemic have triggered a rush to buy, or "panic buying" as the British call it. Not only food products such as pasta, milk, flour, eggs, water, but also toilet paper and tissue products are disappearing from the shelves.

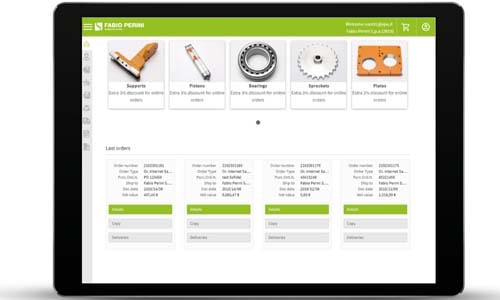

Many companies in the tissue industry around the world have increased production to the maximum, however exposing machines to high risk of failure, and some of them do not have the ability to produce more. This is why Fabio Perini and MTC, Körber companies in the tissue division, thanks to their leadership in the sector, their financial stability, and their strong worldwide presence, have decided to make available in a short time a selection of standard machines and lines for converting and packaging. "In addition to the health emergency that we are facing globally, as a company we are committed to further develop our activities in order to respond promptly to the current production needs of the market,” comments Mauro Luna, global sales director, Fabio Perini. “In this historical moment the advantage of being able to deliver converting and packaging machines in a fast way is certainly an added value that we can offer our customers." Several machines and lines are available such as, for example, for converting, the Constellation S8 and Proxima S6 or for folded products the Star M2 Napkin Folder, for packaging the A6T and CMW208 packaging machines. All can be delivered worldwide in less than four months. On the website: northamerica.fabioperini.com/equipment, customers can find the available technologies with features and benefits and the possibility to contact directly the company's sales team for information and quotes. The fast procurement and delivery of spare parts is also very important because it minimizes downtime. Fabio Perini, through the Spares Online e-commerce platform, provides over 80,000 spare parts, all available for fast delivery. On the webshop, available 24/24 from all devices, the customer can keep track of the order phases: check stock availability and delivery dates in real time, print commercial documents and track the order until it is delivered to his plant. The webshop also allows the creation of wishlists for repetitive orders and enables to receive personalized offers and promotions.

"During this period the production of equipment is pushed to its maximum with demands that far exceed normal use,” notes Gianfranco Agnusdei, global customer service director, Fabio Perini. “Unexpected equipment failure can lead to costly downtime and delays. Investing in and storing spare parts can help maximize production time and keep operations running smoothly. It is therefore critical to have an adequate supply of OEM spare parts that can help maximize operations." |