Heavy Vehicle Simulator Testing

Print this Article | Send to Colleague

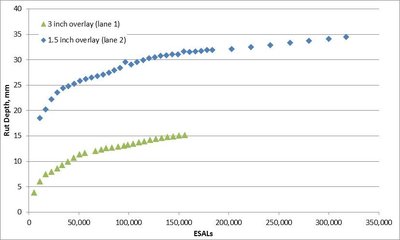

At this pace, the machine is able to apply about 30,000 passes (30,000 ESALs) per week. The testing has been progressing well while kinks are being worked out of the HVS, instrumentation, and data collection plans. One of the biggest lessons learned so far is that, with concentrated loading, the subgrade needs to be stiffer than what VDOT might typically use. The chart below shows that the HVS is measuring rut depths (via an on board laser profiler) of more than 1/2-inch and in some instances more than 1-inch. In addition to the rut depth, other instruments imbedded within the pavement structure include pressure cells and strain gauges. The measurements from these instruments will be used to help quantify performance of a pavement built with CCPR and thinner overlays than those used at the National Center for Asphalt Technology (NCAT) test track and I-81. Future testing will consider changes in mix design approaches as well as resistance to cracking.