VAA Round Robin — Preparing Homogeneous Samples (Part 2 of 5)

Print this Article | Send to Colleague

In a testing program, there are four main sources of potential variability. The three most common variables investigated are people, equipment and processes. However, one of the first sources in the evaluation should be the asphalt mixture – it is consistent. Unless painstakingly prepared in a lab, the odds of getting a 100% repeatable mix from an asphalt plant are slim to none. Just a few differences in gradation or AC content can influence results.

For past round robin lab studies, materials were sampled from a mini-stockpile (see picture below). The contractor would dump material on the ground and technicians would fill bags or boxes with mix for distribution. Depending on the asphalt mixture, some variability was expected – particularly mixes with larger top-sized aggregate. The main benefit for this approach was time and cost; however, the down side was the introduction of the fourth variable – mix differences resulting

from production.

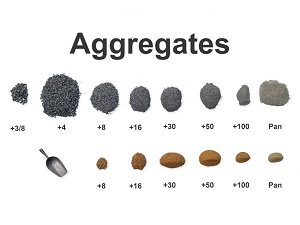

To remove the sample variable for this Round Robin, the VAA decided to spend the time and money to eliminate mix variability in order to concentrate on the people, equipment and process variability. For this effort, a SM-9.5A virgin mix with only 2 aggregate sources was designed. The two aggregate sources selected were – granite and natural sand. Each aggregate was sieved down on individual sieves and then combined to create the mix. This was to control the gradation and specific gravity for the individual samples.

To keep everything consistent, all the samples were mixed by the same technician and every sample was mixed for one minute, then placed in a waxed lined box for distribution.

To monitor and control the lab production process, the third party lab that produced all the samples ran random quality control tests during production. There were five (5) samples tested for each of four (4) specific test (Gmm, Gmb, AC, and Gradation). The results for each test were compared to the design and evaluated for variability. Once completed, the results were averaged to develop a target for evaluating each sample result submitted. Then, a D2S (Difference in 2 Samples) analysis was used to determine if a sample met the acceptable tolerance for each individual test. The D2S limits were provided by VDOT and are used in the department’s MITS/PLAID system. The table below contains the limits.

| Test | Target | D2S |

| Gmm(Rice) | 2.433 | 0.024 |

| Gmb (Bulk Specific Gravity) | 2.341 | 0.042 |

| Asphalt Content | 6.30 (Furnace Correction Factor 0.38) | 0.33 |

Since a great deal of time and effort was used to prepare the samples, mixture variability was minimized in this Round Robin. Therefore, differences between the participating labs results and the target values can be attributed to differences in technicians, equipment and/or testing procedures. Large variability, even when the D2S analysis passes, points to a potential problem that needs to be addressed.

In the December edition of Asphalt News, results from the most basic test – Maximum Specific Gravity, or Rice will be discussed. Also, if you did not participate and still want to or if you want to retest, it’s not too late. VAA still has a few samples available. Contact Mike Dudley at VAA.