VAA Round Robin – Are You Too Bulky or Lean? (Part 4 of 5)

Print this Article | Send to Colleague

The new year brings resolutions — I’m going to drink less, travel more, lose weight, and so on. After a holiday season filled with eating, most of us are a little bulky after all. In the asphalt world, however, bulky is not necessarily a bad thing — it helps us know if we have the proper amount of air voids in the compacted mix. Last month’s article was about the Theoretical Maximum Specific Gravity or Rice value of an asphalt sample; this month we will discuss the Bulk Specific Gravity and the Round Robin results.

So, what is the Bulk Specific Gravity (Gmb)? Is it heavier or lighter than the Maximum Specific Gravity or Rice? Simply put, it is defined as the ratio of a sample’s mass, including any water permeable voids, compared to the mass of an equal volume of water at the same temperature. In layman’s terms, you are measuring the air voids in a compacted sample. By knowing the Bulk Specific Gravity and the Rice value, the percentage of air voids can be calculated. And remember, the Bulk is always less than the Rice since the Rice has no air voids.

Technicians use volumetric properties to gauge the quality of a mix, but in reality these values are simply calculations based on a few lab tests which are primarily focused on the bulk specific gravity result. The Gmb is involved in most key calculations including air voids, VMA and indirectly VFA. Correct and accurate bulk specific gravity determinations are vital to be able to properly design and control an asphalt mixture.

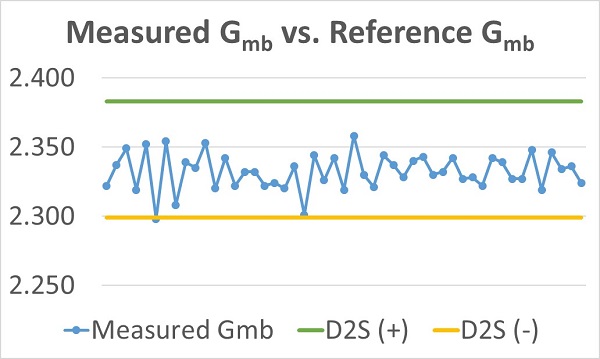

For this Round Robin, 49 samples were submitted using four different models of gyratory compactors. Using five samples randomly selected during the production of the samples as quality control (QC), an average Gmb of 2.341 was established and became the reference value. The samples ranged from a low of 2.335 to a high of 2.346 with a standard deviation of 0.004. The same technician, using the same equipment, was used to minimize technician and equipment variability impacts, therefore focusing on mix variability during production.

While during normal mix testing, a VDOT split sample would be compared to the contractor’s results. Through proper truck sampling and quartering methods in the lab, the two split samples are considered equal and only technician and equipment variability would lead to differences in results. Unfortunately, some material variability still exists. For this Round Robin effort as discussed in a previous article, all mixes were "identical" since they were produced in the lab on a sample by sample basis.

To analyze the 49 samples, the VDOT D2S tolerance for the Bulk Specific Gravity Test of 0.042 was used. Each individual sample was compared to the reference Gmb value of 2.341, so to have an acceptable Gmb the result had to be between 2.299 – 2.383 (see graph). By observing the graph, all but two samples were within the D2S criteria. The reason for the failures was due to testing and technician errors. Even with the two borderline results, the average Gmb was 2.332 with a standard deviation of 0.013. This high level of repeatability or low standard deviation demonstrated the participating technicians’ ability to compact gyratory samples, perform the Bulk Specific Gravity test, and calculate the results.

If anyone has a question about their specific result, please contact Mike Dudley at MDudley@VAAsphalt.com. Stay tuned for next month when the Furnace Oven results will be discussed.