When The Heat Is On - What Do We Learn? (Part 5 of 5)

Print this Article | Send to Colleague

If you can’t stand the heat, get out of the kitchen! For the asphalt producer, their lab is the kitchen and the heat is always on. Most labs have three to four ovens, and the NCAT ignition oven by far is the hottest. While a kitchen oven is used to bake, the ignition oven is designed to burn off asphalt and leave the rocks behind.

The two primary components of asphalt mix are Aggregate and Asphalt Cement (AC). Yet when asphalt properties or performance measures are discussed, these components are often overlooked and the focus is on other test results. The way to ensure good performance is to maintain proper control of the aggregate gradation and AC content during the production process.

To measure the asphalt content and aggregate gradation the materials must first be separated. Prior to the invention of the NCAT Furnace, the standard process to measure the AC of a sample was with solvent extractions, typically the reflux method. Unfortunately, this method utilized hazardous chemicals and took the better part of a day to complete a test result. The NCAT Furnace reduced testing time significantly and removed the hazardous chemicals from the laboratory. Now technicians can measure the AC in a mix in less than an hour and verify the gradation in another hour or two.

The NCAT Furnace is the standard in Virginia for measuring Asphalt Content in an asphalt mixture sample. The furnace temperature heats to 538°C (1000°F) which ignites and burns all the asphalt binder and additives from the sample. An automated weighing system monitors the weight loss to determine when the test is complete. The total weight loss (minus a correction factor) will show the amount of asphalt cement that was in the sample. The furnace correction factor is established during the mix design phase and accounts for any material loss other than asphalt cement that will occur during the violent burn inside the furnace.

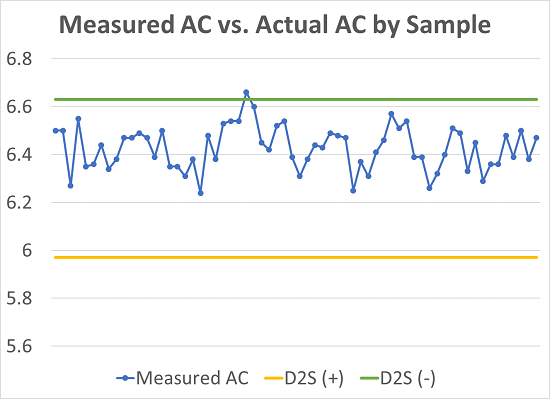

For this Round Robin, a virgin aggregate blend was mixed with 6.30% asphalt cement. There were 5 production samples tested to establish a furnace correction factor of 0.38. There were sixty-four (64) samples submitted that were tested in different furnaces across the state. Each individual sample, after applying a single oven correction factor from the mix design process, was compared to the target AC of 6.30% with the VDOT D2S tolerance of 0.33%. Therefore, to have an acceptable AC; test results had to be between 6.63% and 5.97% (see graph) in the one-to-one comparison. From the individual lab results, the average of the sixty-four samples submitted was 6.43% with a standard deviation of 0.091. Additional investigation is necessary to determine why the average of the 5 QC samples is different than the production samples.

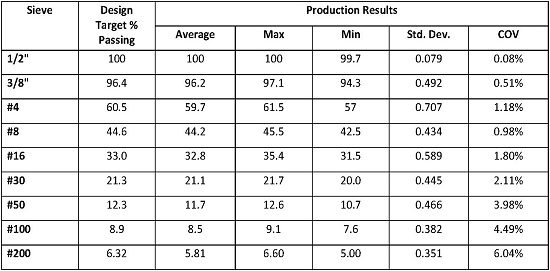

The gradation results were also compared to the targets established from the production QC samples. Because of the number of sieves compared, a graph or table is not included in this article. However, all sample gradations compared to the QC gradations meet VDOT’s D2S requirements. Additionally, the Round Robin evaluated the variation on each sieve. The table below shows the low coefficient of variation on each sieve.

Based on the feedback and benefits each participating lab has shared, the Virginia Asphalt Association plans to conduct a second Round Robin in 2018. The focus of that Round Robin will be sampling procedures and proper splitting of bulk samples to assess the potential for variation. Stay tuned for more information as it becomes available.